An all-optical laser ultrasonic measurement method for internal defects of materials

A technology of internal defects and laser ultrasound, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, can solve the problems of difficult detection of tiny internal defects, inability to accurately locate three-dimensional positions, and great influence on surface quality, so as to improve excitation Efficiency, ease of operation, effect of changing directionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

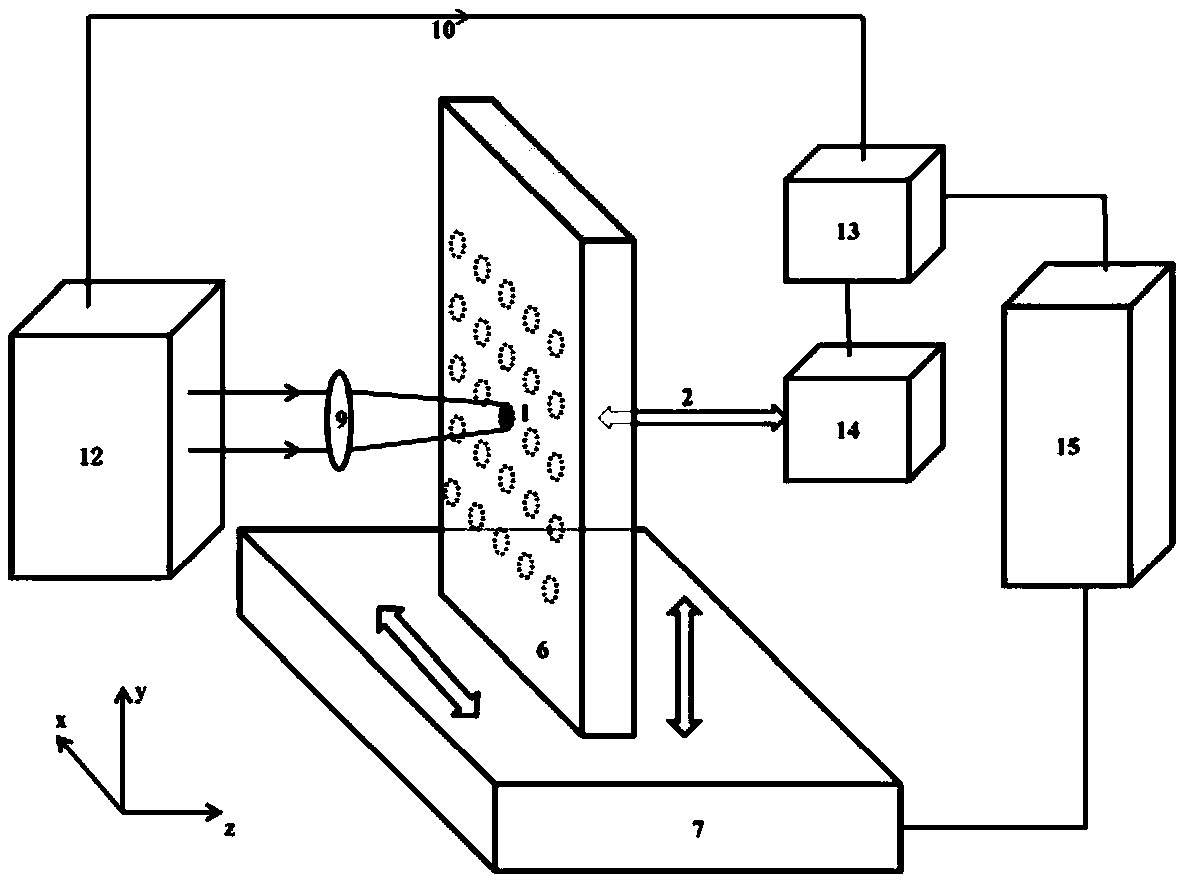

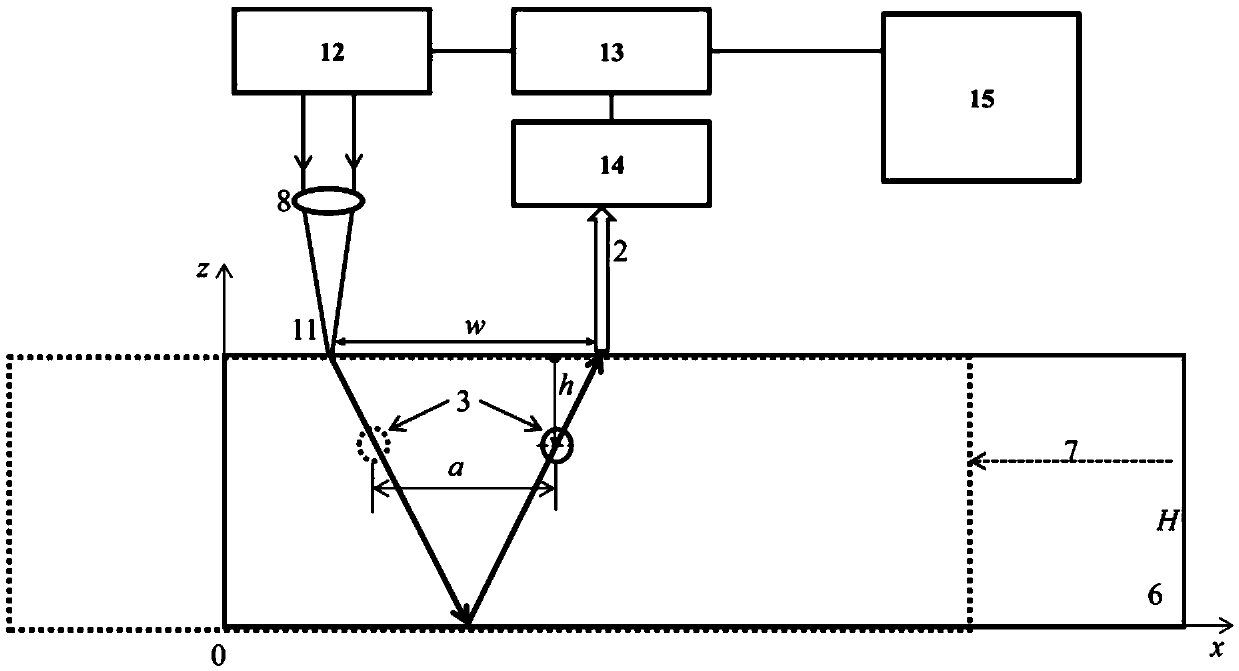

[0029] The invention is an all-optical laser ultrasonic measurement method for internal defects of materials, which comprises two steps,

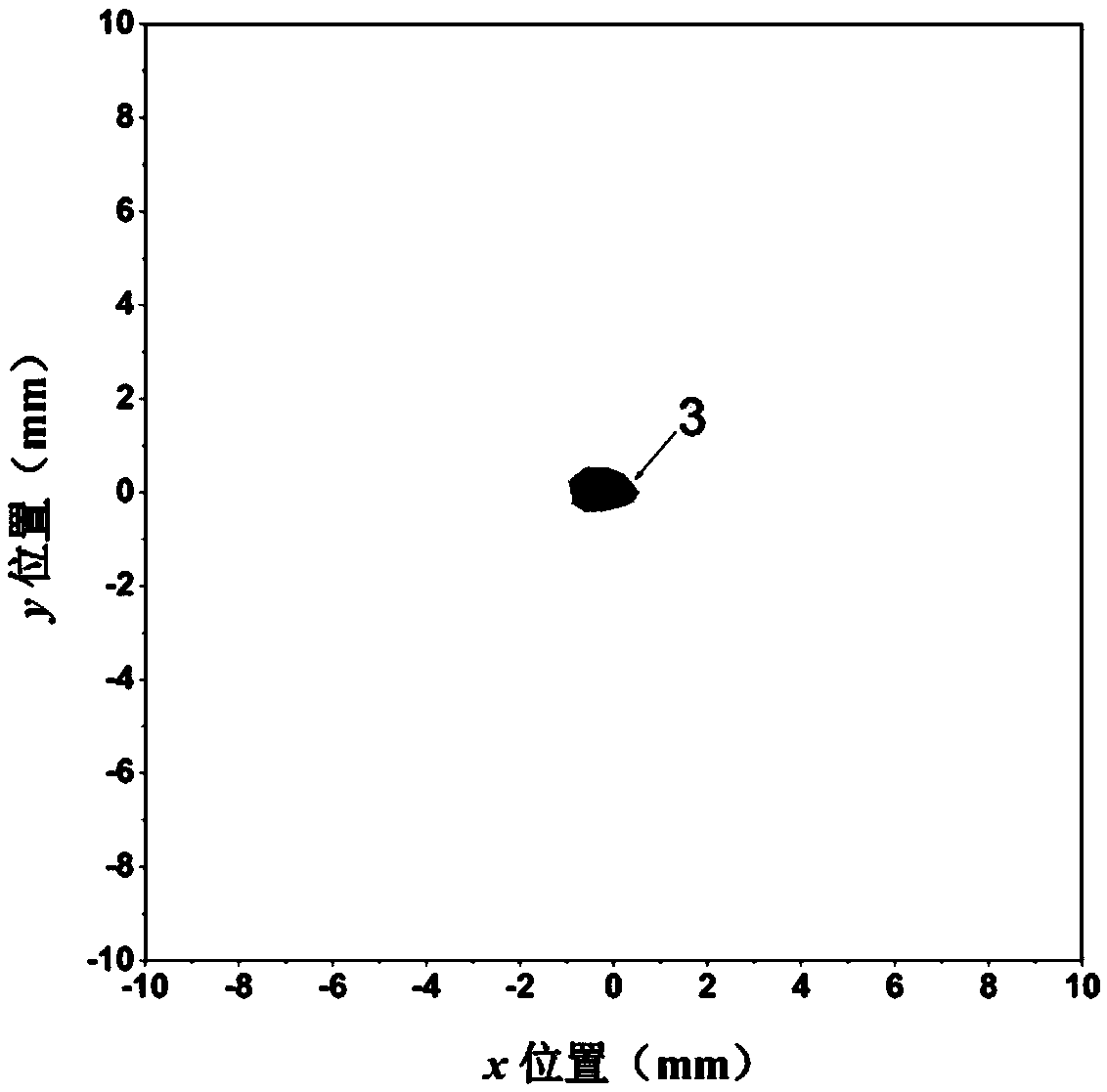

[0030] Step 1: Measure the two-dimensional position and size of the internal defect of the tested object 6 on the x-y plane;

[0031] Step 2: Determining the depth of the internal defect of the tested object 6 in the z direction.

[0032] Step 1 is as specific as figure 1 As shown in the figure, the pulsed laser circular spot 1 is used to irradiate the surface of the measured object 6 to excite the ultrasonic bulk wave, and the ultrasonic bulk wave propagates to the inside of the measured object 6, and the laser vibrometer 14 is used to excite the probe light 2 on the measured object 6. The ultrasonic body wave is detected at the center of the other side, and the detection waveform of the ultrasonic body wave detected by the laser vibrometer 14 is recorded by the oscilloscope 13 connected to the laser vibrometer 14, and the measured object...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com