Silver-loaded silver bromate visible-light-induced photocatalyst and preparation method thereof

A photocatalyst, silver bromate technology, applied in the field of photocatalytic materials, can solve the problems of high carrier recombination rate, poor visible light absorption, easy photocorrosion, etc., to improve electron mobility, improve photocatalytic performance, reduce centrifugal force effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

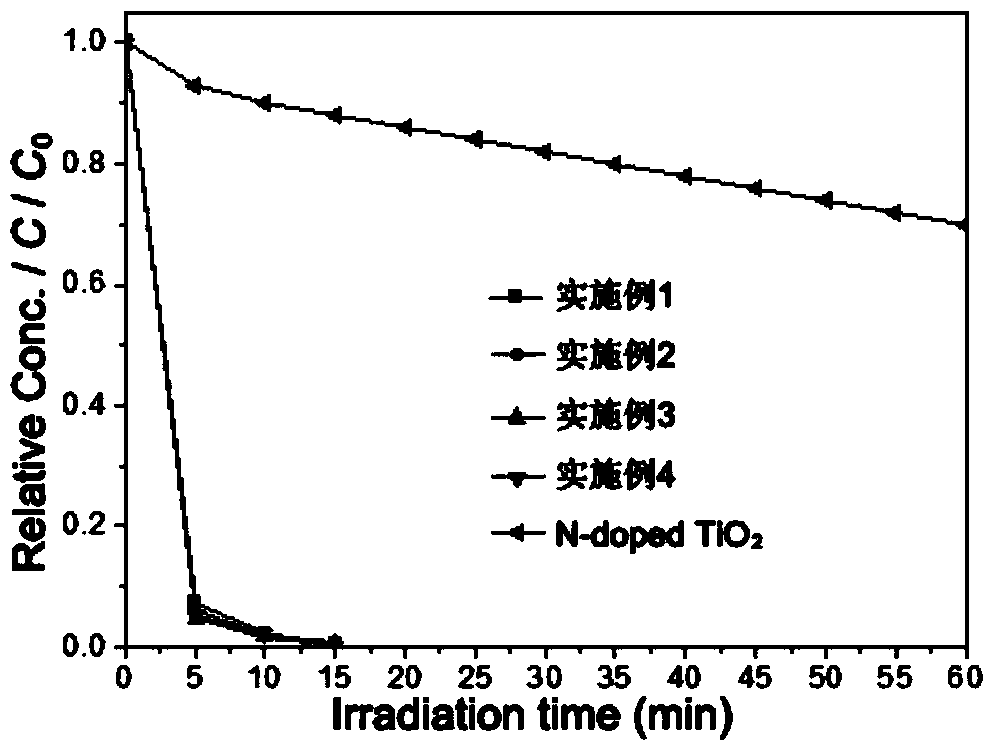

[0025] Weigh 5.02g of potassium bromate, dissolve it in 60mL of water, weigh 5.42g of silver nitrate, dissolve it in 60mL of water, add the silver nitrate solution into the potassium bromate solution at room temperature and under stirring, and continue stirring for 30min to obtain a white suspension; then warm up to 40 o C. Add 0.08g of glucose dissolved in 8mL of water to the suspension of silver bromate under stirring, stir for 1h, filter, wash, 50 o C dried for 4h to obtain a gray powder.

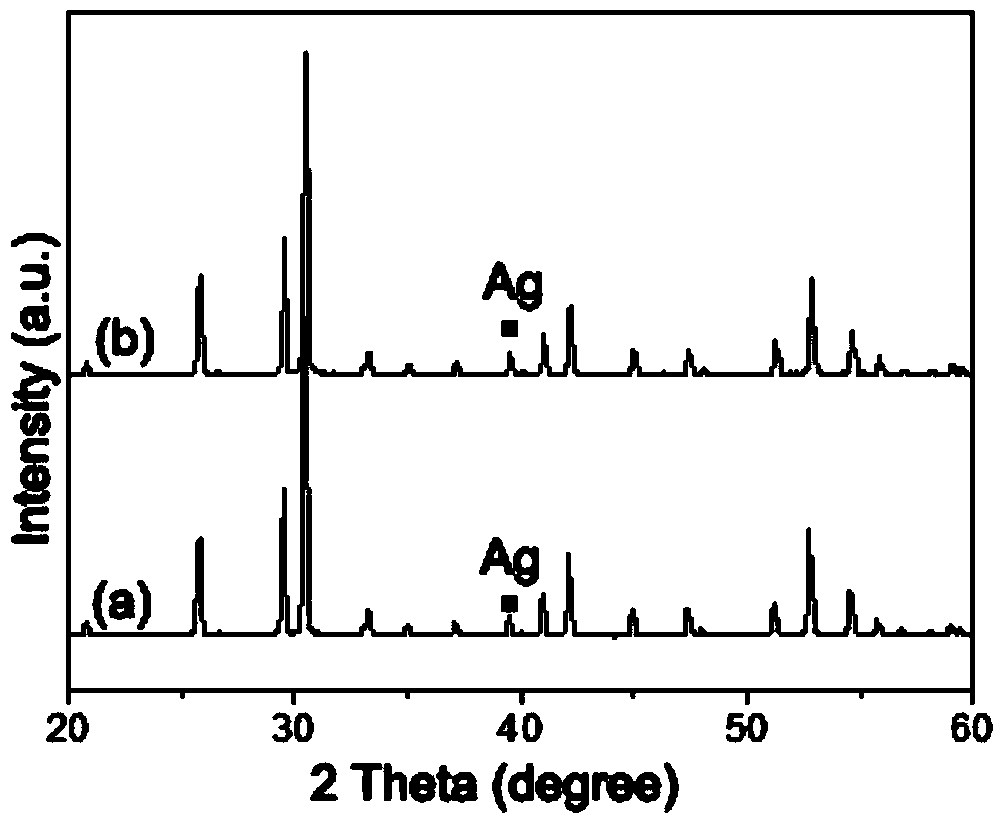

[0026] attached figure 2 (a) is the X-ray diffraction pattern of the sample obtained in this example. It can be seen from the figure that the product is silver bromate. Since the diffraction peak of silver bromate is very strong and sharp, and because the amount of Ag loaded is relatively low, so The diffraction peak of Ag in the X-ray diffraction pattern is very weak. attached image 3 It is a TEM photo of the product obtained in this example. It can be seen from the figure that ...

Embodiment 2

[0028] Weigh 2.83g potassium bromate, dissolve it in 20mL water, weigh 2.93g silver nitrate, dissolve it in 20mL water, heat the potassium bromate solution to 40 o C, then silver nitrate solution was added, and the reaction was stirred for 1 h to obtain a white suspension. Weigh 0.007g of potassium borohydride, dissolve it in 2mL of water, add the potassium borohydride solution under the condition of stirring to obtain a gray suspension, and continue at 40 o Stir at C for 30min, filter, wash, 80 o C dried for 2 h to obtain a dark gray powder.

[0029] attached figure 2 (b) is the X-ray diffraction pattern of the sample obtained in this example. It can be seen from the figure that the product is silver bromate. Since the diffraction peak of silver bromate is very strong and sharp, and because the amount of Ag loaded is relatively low, so The diffraction peak of Ag in the X-ray diffraction pattern is very weak. attached Figure 4 It is a TEM photo of the product obtained i...

Embodiment 3

[0031] Weigh 6.04g of sodium bromate, dissolve it in 40mL of water, weigh 7.2g of silver nitrate, dissolve it in 30mL of water, add the sodium bromate solution to the solution of silver nitrate under stirring, and heat the mixed solution to 50 oC. Stir for 40min to obtain a white suspension; dissolve 0.08g of ascorbic acid in 5mL of water, add it into the suspension of silver bromate while stirring, and turn it into a gray suspension, filter and wash after stirring for 30min, and wash at 60 o C dried for 3.6h to obtain a dark gray powder.

[0032] attached Figure 5 It is a TEM photo of the product obtained in this example. It can be seen from the figure that the prepared samples are particles with a particle size between 250 and 600 nanometers, and the surface is covered with small particles with an average particle size of about 50 nanometers, which are Ag particles obtained by in situ reduction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com