Method for preparing graphene by using disposable paper tableware as raw material

A one-time, graphene technology, applied in the direction of graphene, nano-carbon, etc., can solve the problems of low yield, reduced ozone, low electrical conductivity, etc., to achieve the effects of high yield, easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

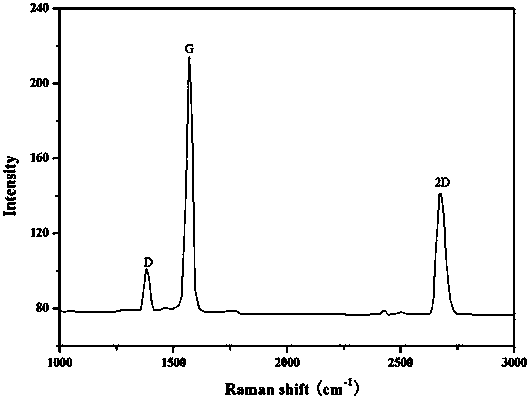

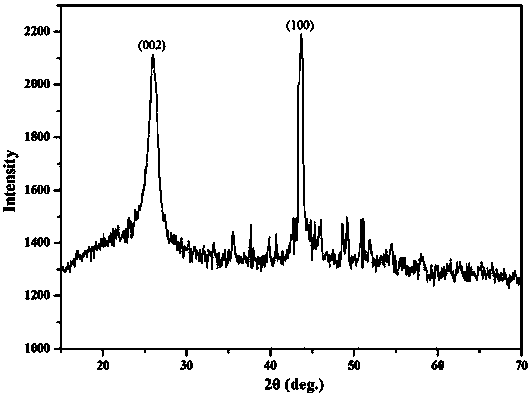

Image

Examples

Embodiment 1

[0021] 1) Crush a 5g disposable paper cup into small pieces and put it into a 1000ml glass beaker, add 300ml of 1 mol / L sodium hydroxide solution, and keep stirring for 48 hours to prepare pulp;

[0022] 2) Filter the pulp to obtain insoluble solids, then add 300 ml of deionized water to wash the insoluble solids, then transfer the aqueous dispersion of the insoluble solids to a centrifuge tube, centrifuge at 3000 rpm for 30 min, dump After centrifuging the liquid in the tube, transfer the solid to a beaker and then add deionized water to wash it, and then go through a cycle of water washing / centrifugation for several times until the pH value is neutral to obtain sodium ion-doped pulp.

[0023] 3) Disperse the pulp obtained in step 2) into 100 ml of 1 mol / L ferric nitrate solution, keep stirring for 12 h under the protection of nitrogen, and then dry the solution in an oven at 60 °C for 48 h to obtain iron salt-loaded pulp.

[0024] 4) Put the dried iron salt-loaded pulp into...

Embodiment 2

[0027] 1) Crush a 13g disposable paper bowl into small pieces and put it into a 1000ml glass beaker, add 450ml of 1 mol / L potassium hydroxide solution, and keep stirring for 60h to prepare pulp;

[0028] 2) Filter the pulp to obtain insoluble solids, then add 450ml of deionized water to wash the insoluble solids, then transfer the aqueous dispersion of insoluble solids to a centrifuge tube, centrifuge at 4000 rpm for 20 minutes, and dump the centrifuge tube After removing the liquid in the solution, transfer the solid to a beaker and then add deionized water to wash it, so that it undergoes a cycle of water washing / centrifugation for several times until the pH value is neutral, and the pulp doped with potassium ions is obtained.

[0029] 3) Disperse the pulp obtained in step 2) into 150ml of 1 mol / L ferric chloride solution, keep stirring for 18h under the protection of nitrogen, and then dry the solution in an oven at 75°C for 42h to obtain pulp loaded with iron salts .

[0...

Embodiment 3

[0033] 1) Crush a 20g disposable paper disk into small pieces and put it into a 1000ml glass beaker, add 600ml of 1 mol / L potassium hydroxide solution, and keep stirring for 72h to prepare pulp;

[0034] 2) Filter the pulp to obtain insoluble solids, then add 600ml of deionized water to wash the insoluble solids, then transfer the aqueous dispersion of insoluble solids to a centrifuge tube, centrifuge at 5000 rpm for 10 minutes, and dump the centrifuge tube After removing the liquid in the solution, transfer the solid to a beaker and then add deionized water to wash it, so that it undergoes a cycle of water washing / centrifugation for several times until the pH value is neutral, and the pulp doped with potassium ions is obtained.

[0035] 3) Disperse the pulp obtained in step 2) into 200 ml of 1 mol / L ferric sulfate solution, stir continuously for 24 h under nitrogen protection, and then dry the solution in an oven at 90°C for 36 h to obtain iron salt-loaded pulp.

[0036] 4) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com