Application of nanometer magnesium oxide in cement base material as expanding agent

A technology of nano-magnesia and cement-based materials, which is applied in the application field of nano-magnesia and can solve problems such as poor volume stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

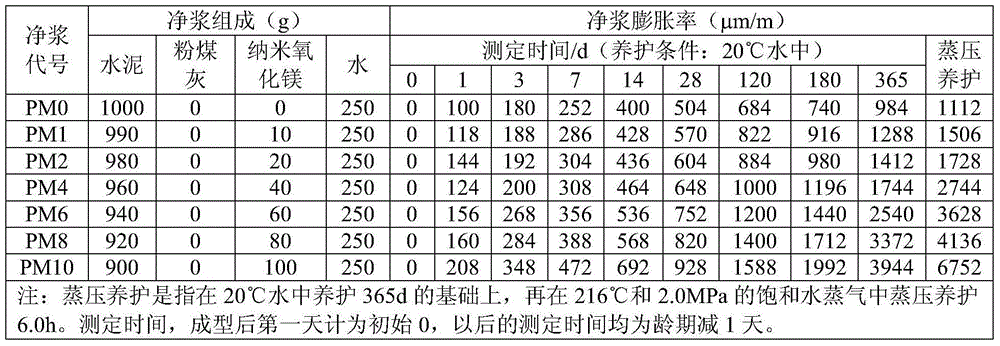

Embodiment 1

[0018] Prepare the cement paste according to the composition of the cement paste in Table 1. Weigh first, then fully dry-mix 52.5-grade ordinary cement and nano-magnesia (provided by Hangzhou Wanjing New Material Co., Ltd., with an average diameter of 50nm, MgO content of 99.90%, and a preparation temperature of 1100-1300°C), and then press the cement Preparation method of clean pulp (GB / T1346-2011) Prepare clean pulp, and mold 3 expansion specimens in a test mold of 25×25×280mm. After curing in a curing box at (20±1)°C for 24 hours, remove the mold and measure its initial length (accurate to 0.001mm). Afterwards, they are all maintained in water at (20±1) °C, and their length is measured during the specified curing time, and the linear expansion rate is finally calculated. And on the basis of curing in 20°C water for 365d, then autoclave curing in an autoclave (216°C and 2.0MPa saturated water vapor) for 6.0h, and then measure its length after cooling to 20°C according to re...

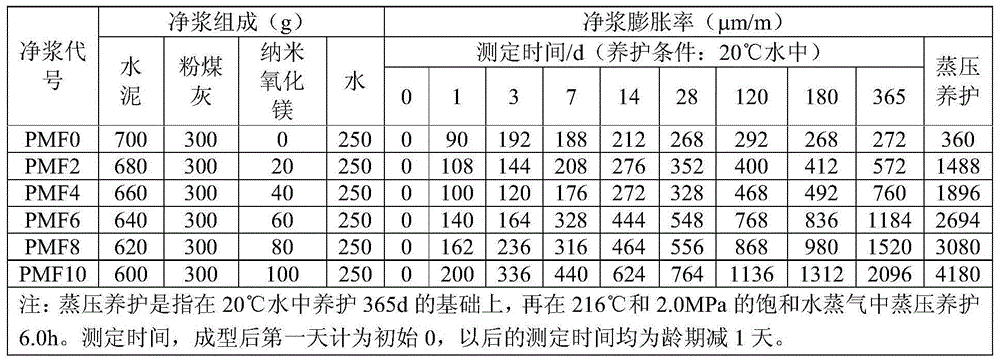

Embodiment 2

[0024] Prepare clean pulp according to the clean pulp composition in Table 2. Weigh first, and then fully dry-mix 52.5-grade ordinary cement, fly ash and nano-magnesia (provided by Hangzhou Wanjing New Material Co., Ltd., with an average diameter of 50nm, a MgO content of 99.90%, and a preparation temperature of 900-1100°C) , and then prepare the cement paste according to the preparation method of cement paste (GB / T1346-2011), and form three expansion specimens in a test mold of 25×25×280mm. After curing in a curing box at (20±1)°C for 24 hours, remove the mold and measure its initial length (accurate to 0.001mm). Afterwards, they are all maintained in water at (20±1) °C, and their length is measured during the specified curing time, and the linear expansion rate is finally calculated. And on the basis of curing in 20°C water for 365d, then autoclave curing in an autoclave (216°C and 2.0MPa saturated water vapor) for 6.0h, and then measure its length after cooling to 20°C acc...

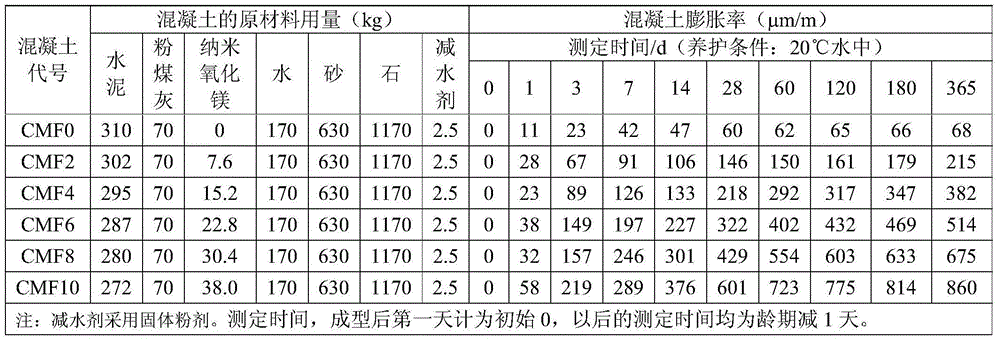

Embodiment 3

[0030]Concrete was prepared according to the amount of concrete raw materials per square meter in Table 3. Weigh first, then dry-mix 52.5-grade ordinary cement, fly ash and nano-magnesia (provided by Hangzhou Wanjing New Material Co., Ltd., with an average diameter of 50nm, a MgO content of 99.90%, and a preparation temperature of 700-900°C) , and then prepare concrete according to the preparation method of ordinary concrete (GB / T50080-2002), and form three expansion specimens in a test mold of 100×100×515mm. After 24 hours of curing in a curing room at (20±2)°C, remove the mold and measure its initial length (accurate to 0.001mm). Afterwards, they are maintained in water at (20±2)°C, and their length is measured during the specified curing time, and the linear expansion rate is finally calculated.

[0031] When the content of nano-magnesium oxide is 0%, 2%, 4%, 6%, 8% and 10%, under the condition of curing in water for 365 days, their concrete linear expansion ratios are 68,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com