A kind of induction furnace rapid repair charge and furnace repair method

A technology for repairing materials and induction furnaces, which is applied in the field of rapid repairing materials and furnace repairs for induction furnaces. It can solve the problems that induction furnaces cannot repair furnaces and shorten repair time, and achieve the elimination of boron mud hazards, shape stability and adhesion combination Strong performance, the effect of improving the service life of the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

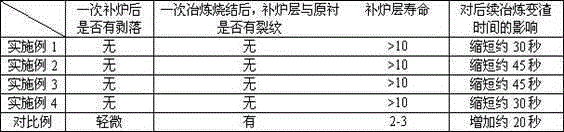

Examples

Embodiment 1

[0024] Ingredients (mass percentage): 30% boron mud, 3% coke powder, 2% silicon carbide powder, 45% magnesia, 20% lime; hot repair furnace for 5 tons of medium frequency induction steelmaking furnace, the furnace lining is made of alumina The smelting steel is high chromium alloy steel, the tapping temperature is 1685°C, and the slagging materials are mainly lime, fluorite and iron oxide. 10 kilograms of rapid furnace repair materials of the present invention are carried out on-line thermal repair furnace, furnace repair materials are prepared by weighing boron mud 30%, coke powder 3%, silicon carbide powder 2%, magnesia 45%, lime 20%, but can not mix; The furnace process is: after the induction furnace smelts and taps steel, first add the first layer of repair materials in the furnace, including boron mud, coke powder and silicon carbide powder. The particle size of boron mud, coke powder and silicon carbide powder should be less than 1mm, and mix evenly Then add it into the ...

Embodiment 2

[0026] Ingredients (mass percentage): boron mud 20%, coke powder 5%, silicon carbide 5%, magnesia 45%, lime 25%;

[0027] The 15-ton medium-frequency induction steelmaking furnace is hot-repaired. The furnace lining is a neutral furnace lining made of alumina. The smelted steel is high-chromium alloy steel. The tapping temperature is 1685°C. The smelting slag-making materials are mainly lime, fluorite and iron oxide. etc. After tapping, there is obvious melting loss on the inner side of the furnace facing the tapping side, and a total of 30 kilograms of rapid repairing materials of the present invention are used for online hot repairing of the furnace. The repairing materials are as follows: boron mud 20%, coke powder 5%, silicon carbide 5% %, 45% magnesia, 25% lime and weigh and prepare materials, but they cannot be mixed. The repairing process is as follows: after the induction furnace smelts steel, first add the first layer of repairing materials in the furnace, including bo...

Embodiment 3

[0029] Ingredients (mass percentage): boron mud 30%, coke powder 4%, silicon carbide 6%, magnesia 40%, lime 20%;

[0030] The 45-ton medium-frequency induction steelmaking furnace is hot repaired. The furnace lining is a neutral furnace lining made of alumina. The smelted steel is tungsten-molybdenum alloy steel. The tapping temperature is 1680 ° C. The smelting slag-making materials are mainly lime, fluorite and iron oxide. etc. After tapping, there is obvious melting loss on the inner side of the furnace facing the tapping side, and a total of 90 kg of rapid repairing materials of the present invention are used for online hot repairing of the furnace. The repairing materials are as follows: boron mud 30%, coke powder 4%, silicon carbide 6 %, 40% magnesia, 20% lime and weigh and prepare materials, but they cannot be mixed. The repairing process is as follows: after the induction furnace smelts steel, first add the first layer of repairing materials in the furnace, including bo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com