Synthetic method of benzyl carbazate

A technology of benzyl carbazate and a synthesis method, which is applied in the synthesis field of benzyl carbazate, can solve the problems of harsh reaction conditions, long production cycle, low comprehensive yield and the like, achieves fewer reaction steps, low production cost, The effect of easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

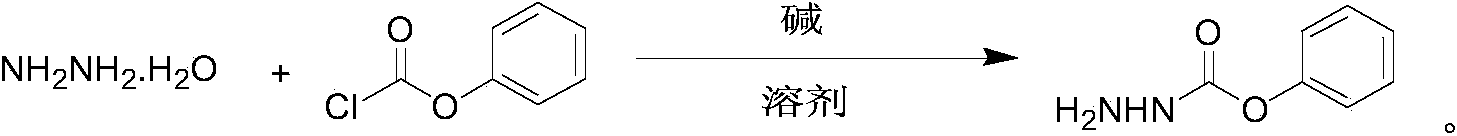

[0024] Embodiment 1: the synthesis of crude product of benzyl carbazate

[0025] In a three-necked reaction flask, add hydrazine hydrate (2.0 mol), potassium carbonate (2.0 mol) and 50 mL of tetrahydrofuran, cool the reaction system to -20°C, and add benzyl chloroformate (2.0 mol) dropwise. After the dropwise addition was completed, the reaction was continued for 2 hours, potassium carbonate was removed by filtration, and washed with water. The organic phase was concentrated to obtain the product (yield 95.0%, purity 96.0%, high performance gas chromatography (GC) internal standard method).

Embodiment 2

[0026] Embodiment 2: Purification of crude product of benzyl carbazate into salt

[0027] In a three-necked reaction flask, 40.0 g of crude benzyl carbazate (96.0% purity, high-performance gas chromatography (GC) internal standard method) and 400 mL of dichloromethane were added, and 80 mL of 30% hydrochloric acid was added dropwise to the reaction system. Solids precipitated in the reaction system. Add 150 mL of water to the reaction system until the solid part dissolves. The organic layer was separated and the aqueous layer was retained. Add 80 mL of ammonia water dropwise to the aqueous layer until the solution becomes alkaline. The aqueous layer was extracted three times with 250 mL of dichloromethane. The organic phase was concentrated to obtain 36.0 g of pure benzyl carbazate (99.5% purity, high performance gas chromatography (GC) internal standard method, yield 90.0%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com