A kind of preparation method of erbium-based multi-ligand rubber vulcanization accelerator

A rubber vulcanization and multi-ligand technology is applied in the synthesis field of erbium-based multi-ligand vulcanization accelerators, which can solve problems such as poor solubility, and achieve the effects of simplifying the process, improving safety, and improving the promotion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of accelerator:

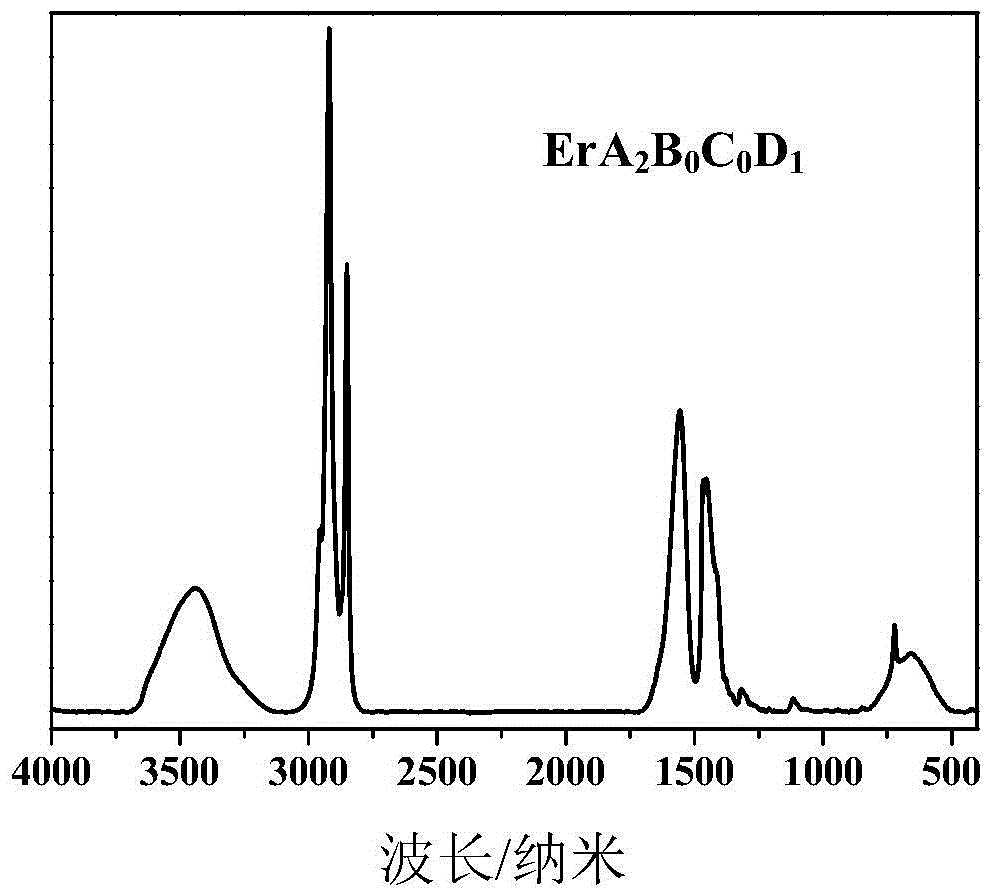

[0044] 0.01molErCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.02mol sodium dimethyl dithiocarbamate in absolute ethanol solution at 60°C, and dissolve 0.01mol triethanolamine in absolute ethanol solution at 60°C. An ethanol solution of sodium dimethyl dithiocarbamate and an ethanol solution of triethanolamine are thoroughly mixed evenly to obtain a mixed solution. Then the above mixed solution was added dropwise to ErCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to constant mass to obtain a flesh-colored solid, the target product ErA 2 B 0 C 0 D. 1 .

Embodiment 2

[0046] The preparation method of accelerator:

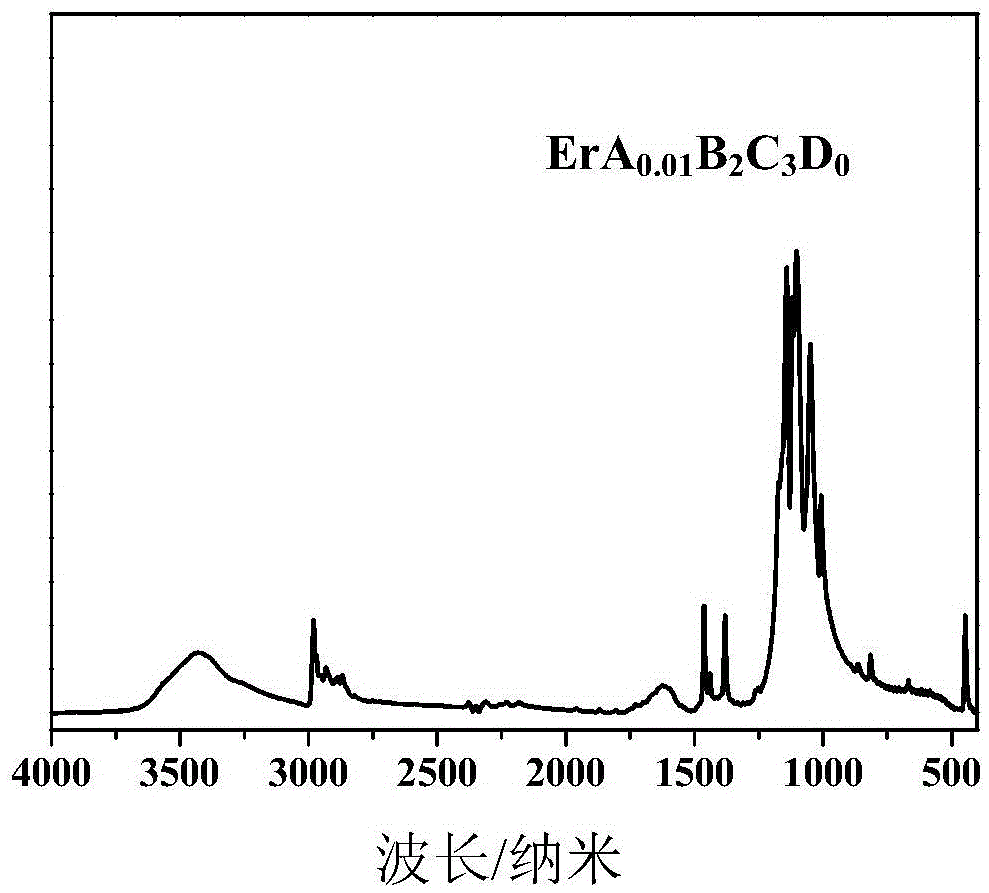

[0047] 0.01molErCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.0001mol sodium dimethyl dithiocarbamate in absolute ethanol at 60°C, dissolve 0.02mol potassium ethyl xanthate in absolute ethanol at 60°C In, 0.03mol citric acid was dissolved in absolute ethanol solution at 60°C. Fully mix the ethanol solution of sodium dimethyl dithiocarbamate, the ethanol solution of potassium ethyl xanthate and the ethanol solution of citric acid to obtain a mixed solution. Then the above mixed solution was added dropwise to ErCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to a constant mass to obtain a powdery yellow powder, the target product ErA 0.01 B 2C 3 D. 0 .

Embodiment 3

[0049] The preparation method of accelerator:

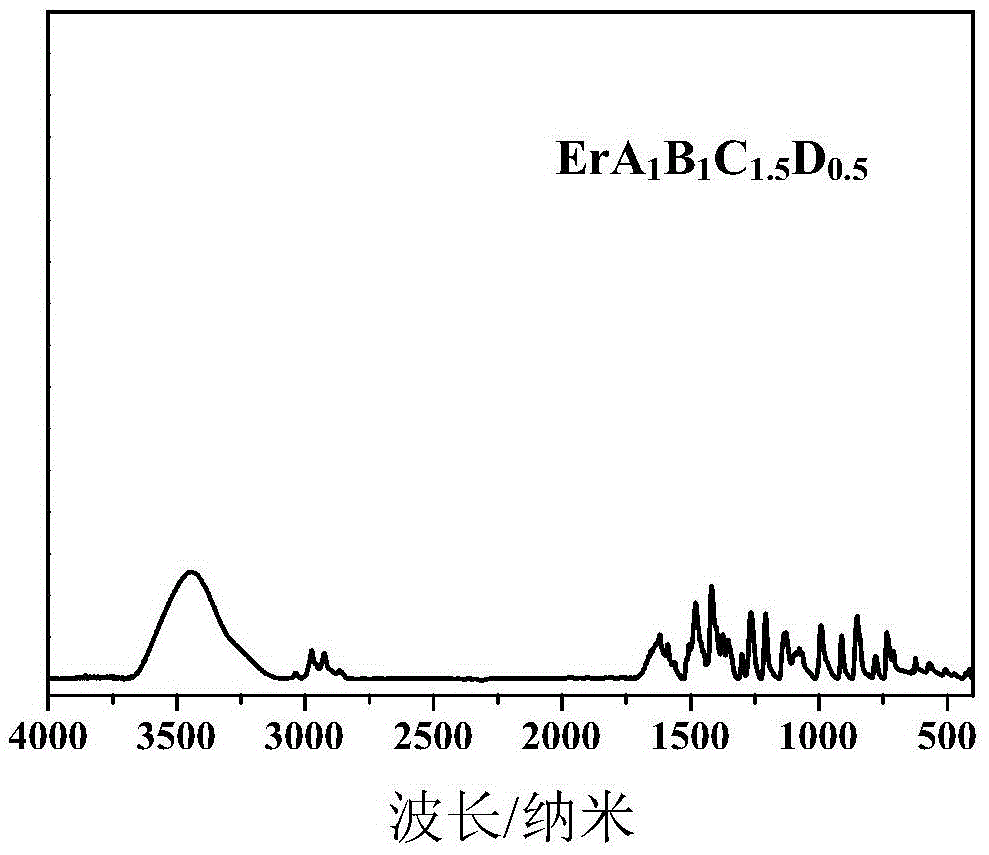

[0050] 0.01molErCl 3 Dissolve in absolute ethanol at 60°C, dissolve 0.01mol sodium dimethyl dithiocarbamate in absolute ethanol at 60°C, dissolve 0.01mol potassium ethyl xanthate in absolute ethanol at 60°C In, 0.015mol citric acid was dissolved in 60°C absolute ethanol solution, and 0.005mol triethanolamine was dissolved in 60°C absolute ethanol solution. Fully mix the ethanol solution of sodium dimethyl dithiocarbamate, the ethanol solution of potassium ethyl xanthate, the ethanol solution of citric acid and the ethanol solution of triethanolamine to obtain a mixed solution. Then the above mixed solution was added dropwise to ErCl 3 in anhydrous ethanol solution, stirred in an oil bath at 80°C for 6h and filtered, and the precipitate was washed with anhydrous ethanol, and placed in CaCl 2 Dry in a desiccant desiccator at 20°C to a constant mass to obtain a flesh-colored powder, the target product ErA 1 B 1 C 1.5 D. 0.5 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com