Method for preparing graphene sponge based on traditional sponge serving as template

A graphene sponge, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve problems such as size limitation, and achieve the effects of high production efficiency, uniform dispersion and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

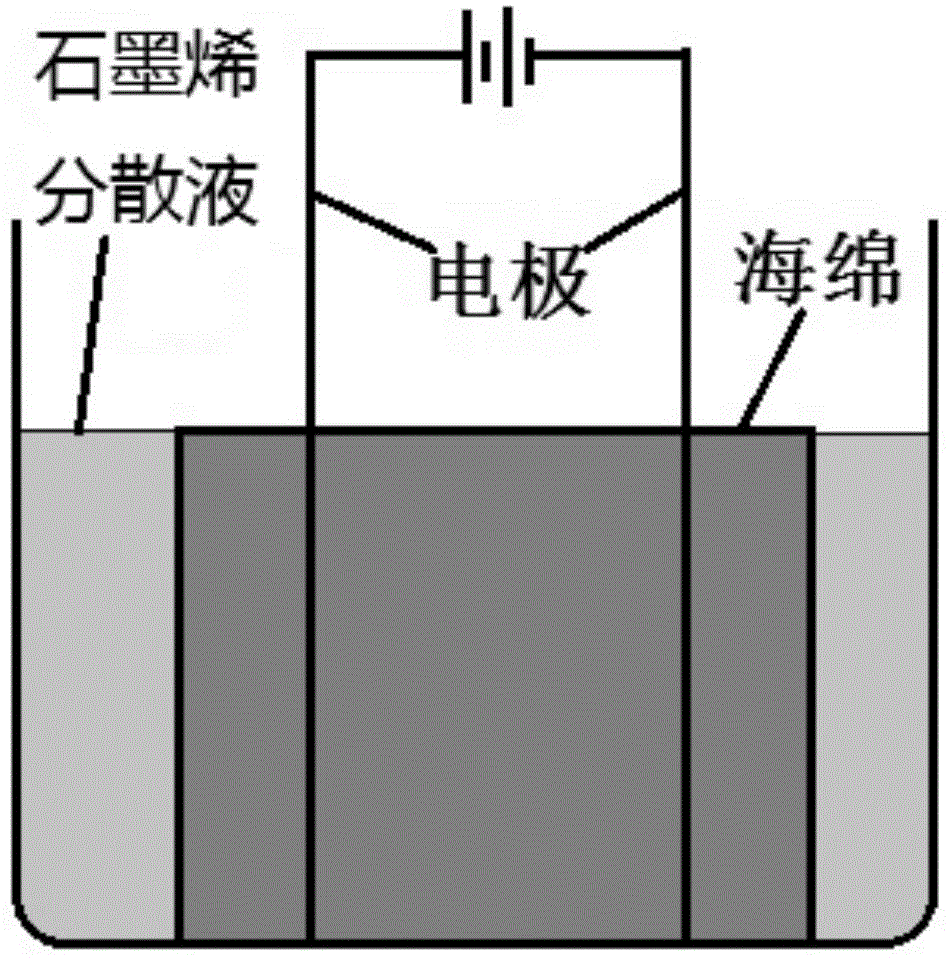

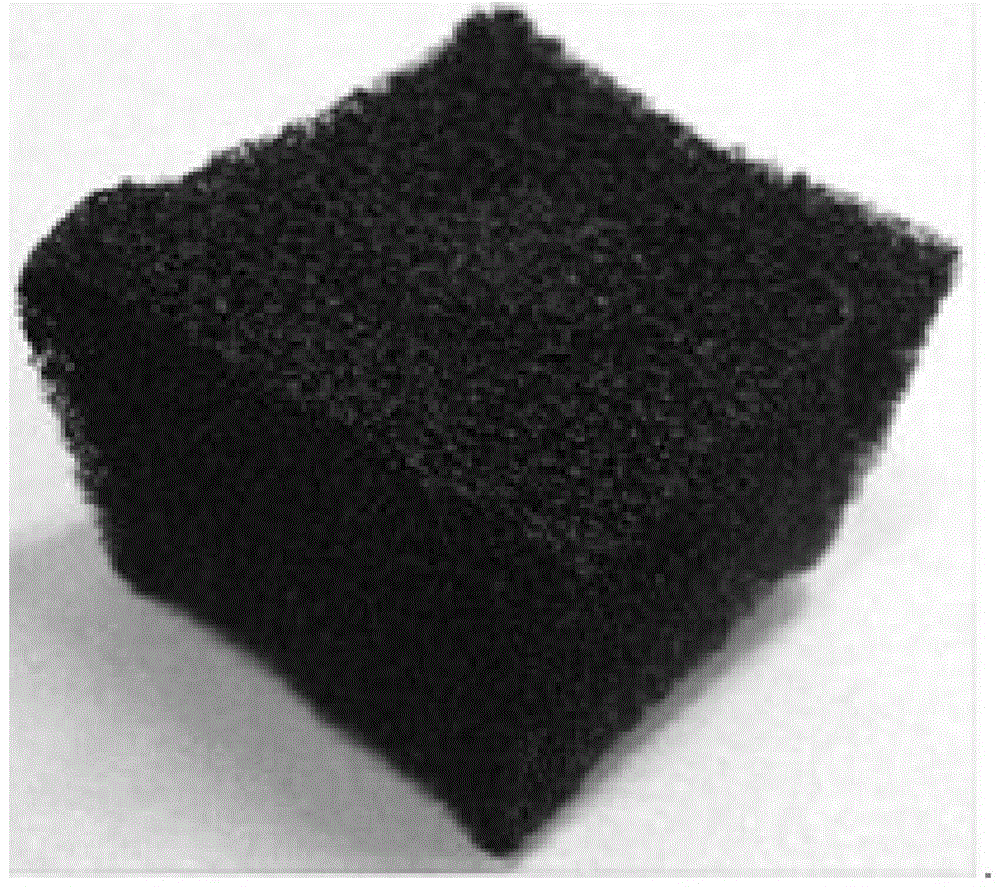

[0023] Specific embodiment one: a kind of method described in this embodiment based on traditional sponge is that template prepares graphene sponge, specifically carries out according to the following steps:

[0024] 1. Preparation of graphene oxide: at a stirring speed of 100r / min to 800r / min, add natural flake graphite to sulfuric acid and phosphoric acid mixed acid to prepare a mixture, stir the mixture for 10min to 60min, and then pour it into the stirred Potassium permanganate is added to the mixture in 3 to 10 times to obtain the mixture after adding potassium permanganate. At a temperature of 30°C to 80°C and a stirring speed of 200r / min to 800r / min, the potassium permanganate will be added The final mixture was placed in a water bath and stirred at a constant temperature for 4h to 20h to obtain a stirred mixture at a constant temperature. Then, the mixture stirred at a constant temperature was added to ice water, and hydrogen peroxide with a mass fraction of 30% was add...

specific Embodiment approach 2

[0036]Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mixed acid of sulfuric acid and phosphoric acid described in step 1 is a mixture of phosphoric acid with a mass fraction of 10% to 85% and sulfuric acid with a mass fraction of 10% to 98%; The volume ratio of the sulfuric acid with a mass fraction of 10%-98% to the phosphoric acid with a mass fraction of 10%-85% is (3-10):1. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0037] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the mass ratio of the volume of sulfuric acid and phosphoric acid mixed acid described in step one to the natural flake graphite is (10mL~120mL): 1g. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com