Natural gas recycling method for compressed natural gas stations

A technology for compressing natural gas and natural gas, which is applied in the container filling method, the container discharging method, and the equipment loaded into the pressure vessel, etc., can solve the problems of natural gas waste and environmental pollution, and achieves reduction of hidden safety hazards, protection of environmental pollution, and avoidance of resources. wasteful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

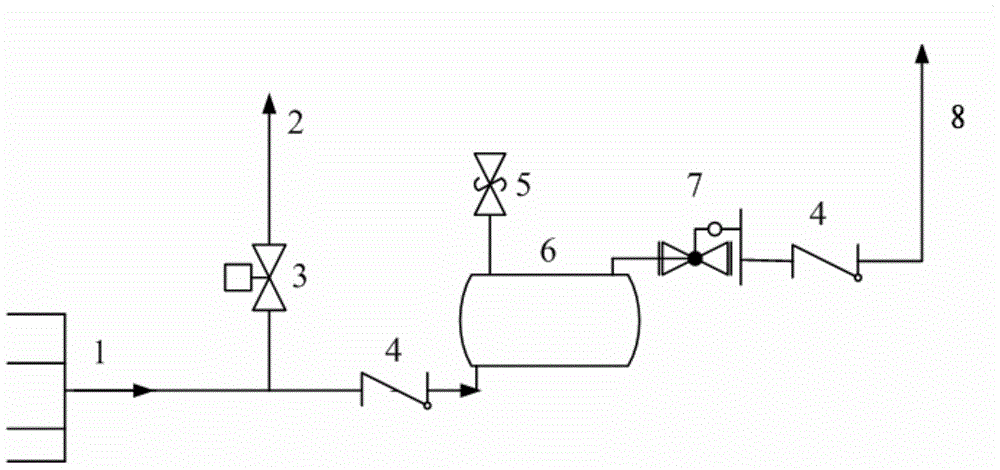

[0022] figure 1 It is one of the schematic flow charts of the method of the present invention. The incoming gas from the venting pipe of the air filling gun merges into the gas collecting main pipe 1. At this time, the control valve 3 on the venting pipeline 2 is closed, and the recovered natural gas passes through the one-way After the isolation valve 4 enters the buffer tank 6 for buffering, it enters the natural gas compressor through the pressure regulator 7 through the one-way isolation valve. The operating conditions of the buffer tank 6 are as follows: the temperature is normal temperature, and the pressure is normal pressure with gauge pressure gauge. When the recovery pipeline pressure drops to the same pressure as the gas pipeline before the compressor, the control valve 3 is opened, and the remaining gas is vented to complete a recovery process.

Embodiment 2

[0024] According to the conditions and steps described in Example 1, the incoming gas from the venting pipe of the air filling gun merges into the gas collecting main pipe 1. At this time, the control valve 3 on the venting pipeline 2 is closed, and the recovered natural gas is isolated in one direction. After the valve 4 enters the buffer tank 6 for buffering, it enters the natural gas compressor through the pressure regulator 7 through the one-way isolation valve. The operating conditions of the buffer tank 6 are as follows: the temperature is 90° C., and the pressure is 25 MPa in terms of gauge pressure. When the recovery pipeline pressure drops to the same pressure as the gas pipeline before the compressor, the control valve 3 is opened, and the remaining gas is vented to complete a recovery process.

Embodiment 3

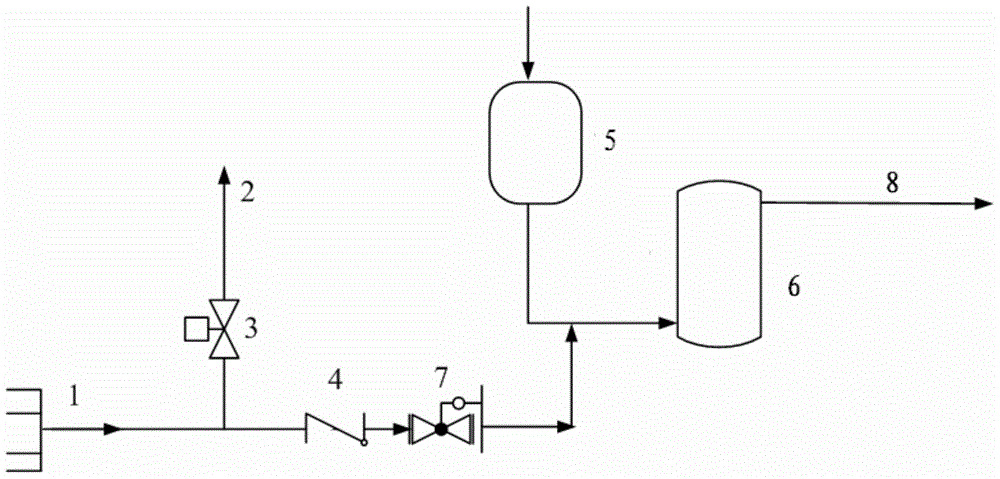

[0026] figure 2 It is the second schematic flow chart of the method of the present invention. The incoming gas from the venting pipe of the air filling gun merges into the gas collecting main pipe 1. At this time, the control valve 3 on the venting pipeline 2 is closed, and the recovered natural gas passes through the one-way The isolation valve 4 enters the buffer tank 6 in front of the compressor through the pressure regulator 7 for buffering, and then enters the compressor together with the natural gas from the pressure regulating metering system or the desulfurization system 5 . The operating conditions of the buffer tank 6 are as follows: the temperature is 50° C., and the pressure is 10 MPa in terms of gauge pressure. When the recovery pipeline pressure drops to the same pressure as the gas pipeline before the compressor, the control valve 3 is opened, and the remaining gas is vented to complete a recovery process.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com