System and method for pre-drying brown coal by utilizing waste heat of power station

A drying system, pre-drying technology, applied in the direction of heating to dry solid materials, combustion methods, drying solid materials, etc., to achieve the effect of alleviating wear and corrosion, high reliability, and small furnace size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

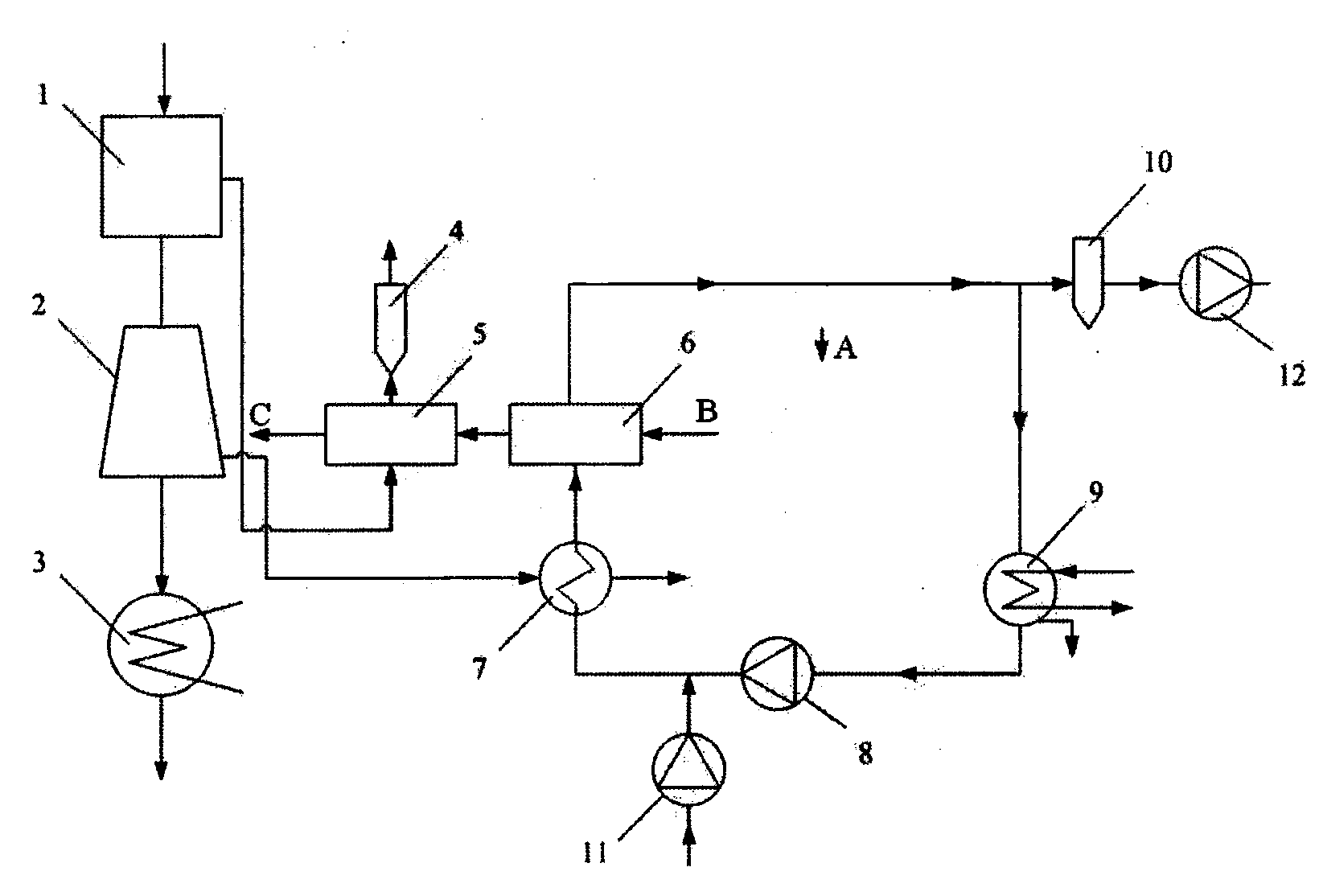

[0043] figure 1 It is a schematic diagram of the system for pre-drying lignite by using the waste heat of the power station in this embodiment. The system for pre-drying lignite by using the waste heat of the power station is divided into two stages, including the first-stage drying system and the second-stage drying system, respectively Air and boiler tail exhaust are used as drying medium. figure 1 In the figure, boiler 1 is connected to steam turbine 2, and steam turbine 2 is connected to condenser 3, A is brown coal, B is wet coal, and C is dry coal.

[0044] The first-stage drying system includes a first-stage dryer 6 , an air heater 7 , a circulating fan 8 , a dehumidifier 9 , a first dust collector 10 , a blower 11 , and an induced draft fan 12 . Wherein, the drying medium is air, part of which comes from the surrounding environment, and part of which comes from the recycling of exhaust gas from the first stage dryer 6 .

[0045] The air in the environment enters from...

Embodiment 2

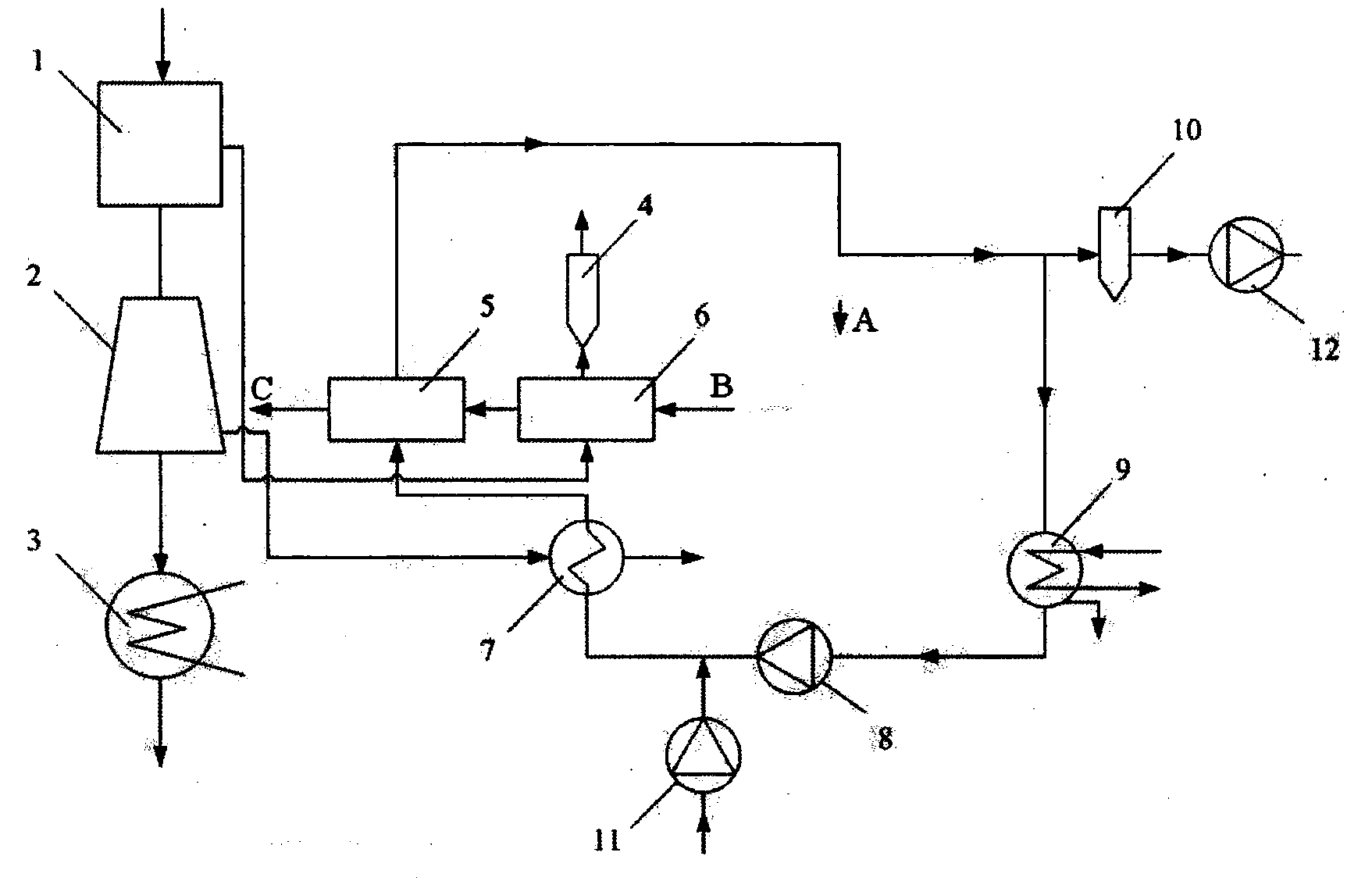

[0050] figure 2 It is a schematic diagram of the system for pre-drying lignite by using the waste heat of the power station in this embodiment. The system for pre-drying lignite by using the waste heat of the power station is divided into two stages, including the first-stage drying system and the second-stage drying system, respectively Use exhaust gas and air at the tail of the boiler as the drying medium. figure 1 In the figure, boiler 1 is connected to steam turbine 2, and steam turbine 2 is connected to condenser 3, A is brown coal, B is wet coal, and C is dry coal.

[0051] The first-stage drying system is composed of a first-stage dryer 6 and a second dust collector 4 . Among them, the drying medium is the flue gas at the tail of the boiler, and the flue gas at the tail of the boiler is directly extracted. The temperature of the flue gas is 100-150 ° C. The flue gas enters the first-stage dryer 6 to dry the lignite, mainly to achieve the purpose of removing the extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com