Gel polymer electrolyte, solid-state battery, preparation method of gel polymer electrolyte and application

A technology of gel polymer and electrolyte, which is applied in the direction of non-aqueous electrolyte batteries, electrolytes, solid electrolytes, etc., can solve the problems of reduced mechanical properties, narrow electrochemical window, etc., to reduce the risk of fire and explosion, high fire resistance, and safety The effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

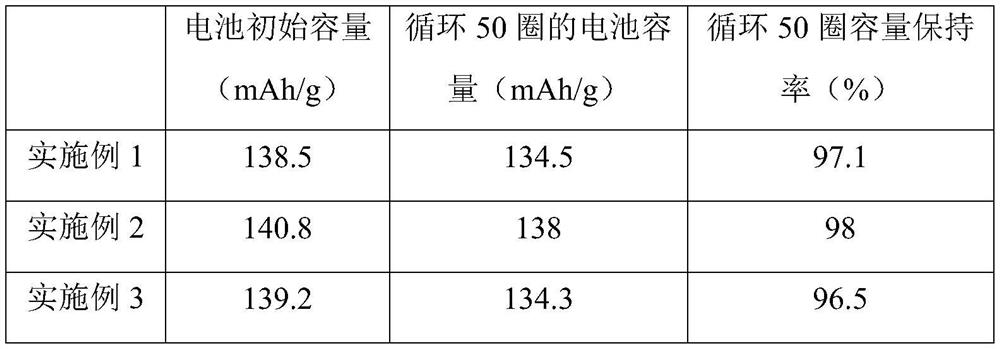

Embodiment 1

[0057] A certain amount of LLZO (Shenzhen Kejing Zhida Technology Co., Ltd.) was weighed and added to TEP / FEC (7:3, v / v) solvent to prepare the first solution with a volume concentration of 20%.

[0058] Acrylonitrile and lithium salt LiTFSI with a mass ratio of 8:2 were weighed and mixed thoroughly, and TEP / FEC (7:3, v / v) solvent was added thereto to form a second solution with a volume concentration of 20%.

[0059] Wherein, the mass ratio of LLZO to acrylonitrile is 45:55, and the precursor liquid is obtained after pouring the first solution into the second solution and mixing well.

[0060] Inject a certain volume of precursor fluid into the glass fiber diaphragm, place the positive and negative electrode sheets on both sides of the diaphragm, encapsulate them in the aluminum-plastic film, react in the sealed aluminum-plastic film at 60°C for 10 hours, and heat the in-situ polymerization reaction to form Electrode / gel polymer electrolyte laminated pouch solid-state battery...

Embodiment 2

[0062] In this example, the mass ratio of LLZO to acrylonitrile is 50:50, and the rest of the preparation process and parameters are the same as in Example 1.

Embodiment 3

[0064] In this example, the mass ratio of LLZO to acrylonitrile is 55:45, and the rest of the preparation process and parameters are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com