Lithium-sulfur battery composite integrated diaphragm, preparation method and lithium-sulfur battery

A lithium-sulfur battery and separator technology, which is applied in the field of composite integrated separator and preparation of lithium-sulfur batteries, can solve the problems of deactivation of active materials, limited effectiveness, and reduced battery capacity, and achieves high flexibility, thermal stability, and structural retention. The effect of stable, high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] According to a first aspect of the present invention, a method for preparing a composite integrated separator for a lithium-sulfur battery is provided, comprising the following steps:

[0050] (a) providing polyamic acid spinning solution;

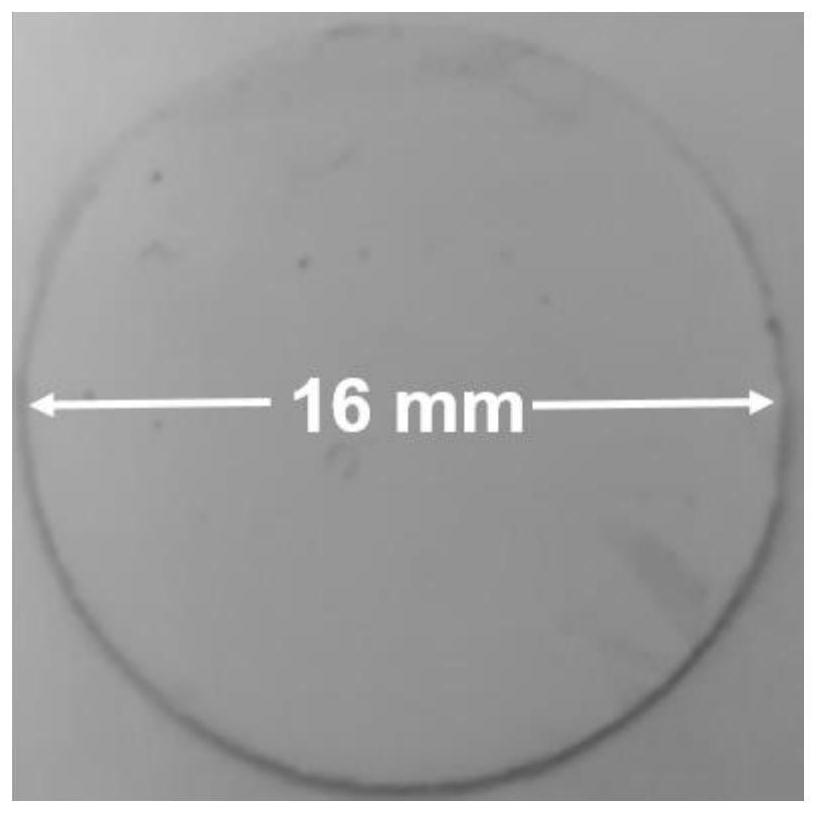

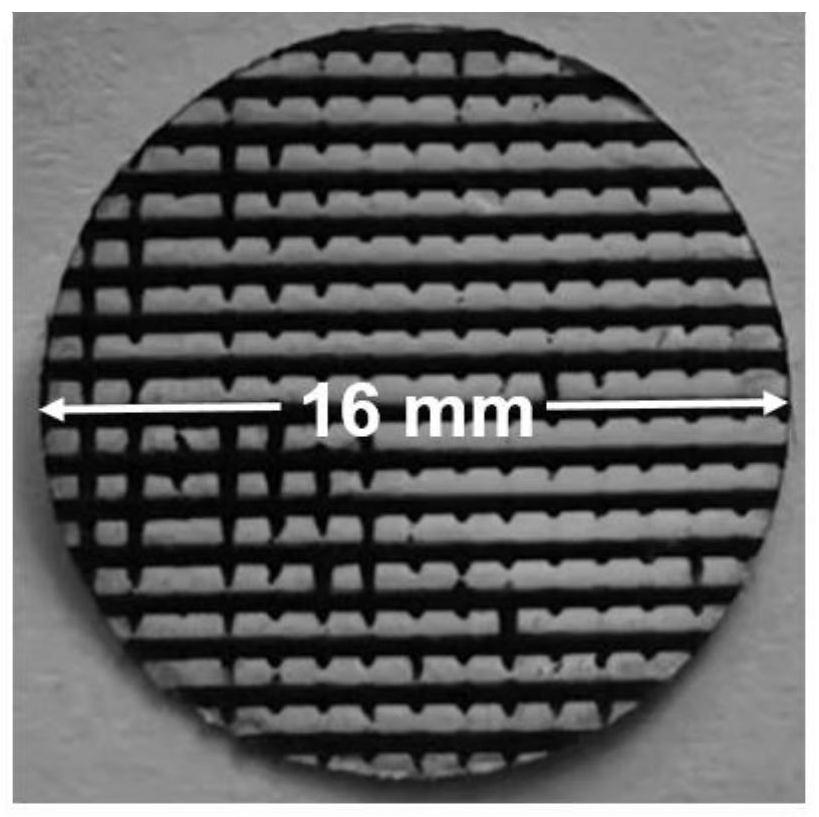

[0051] Electrospinning the polyamic acid spinning solution to obtain a polyamic acid fiber membrane;

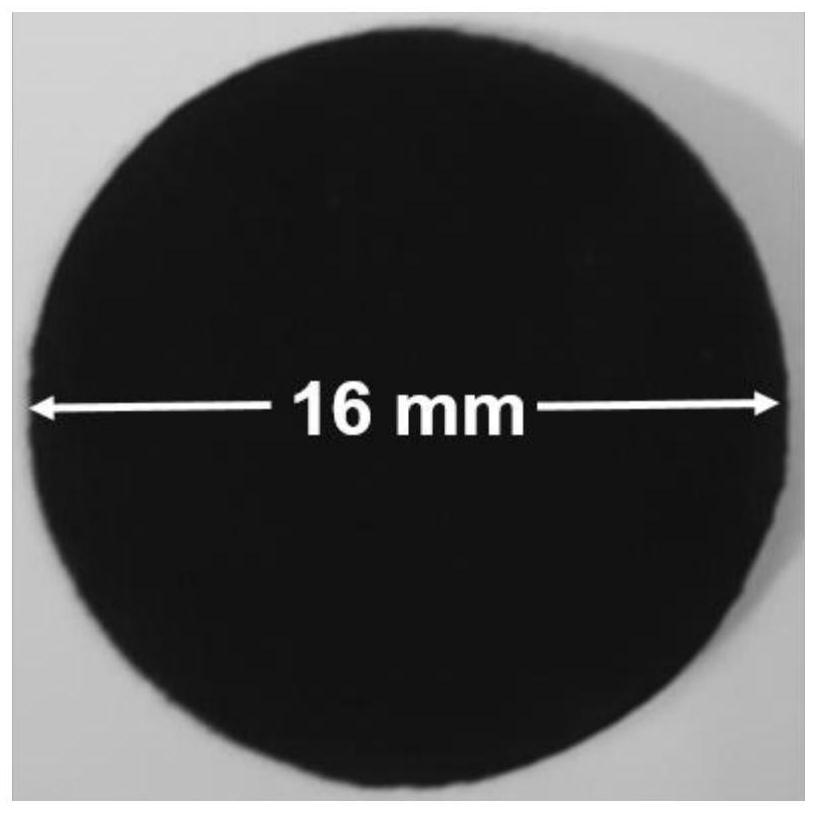

[0052] (b) thermally imidizing the polyamic acid fiber film in air to obtain a polyimide fiber film;

[0053] (c) Using CO 2 The laser irradiates the surface of the polyimide fiber film to obtain a composite integrated separator for a lithium-sulfur battery.

[0054] Specifically, in step (a), the polyamic acid spinning solution is treated by electrospinning, which can ensure that the obtained polyamic acid fiber membrane has high flexibility and thermal stability, and ensures the subsequent CO 2 The underlying structure of the polyimide fiber membrane remains stable during laser processing.

[0055] In step (b), thermal imidiz...

Embodiment approach

[0061] As an optional embodiment of the present invention, the preparation method of polyamic acid spinning solution comprises the following steps:

[0062] The diamine, the dianhydride and the solvent are mixed and reacted to obtain a polyamic acid spinning solution.

[0063] Preferably, the diamine includes any one or a combination of at least two of 4,4'-diaminodiphenyl ether, p-phenylenediamine or 2,2'-bis(trifluoromethyl)diaminobiphenyl , more preferably 4,4'-diaminodiphenyl ether;

[0064] Preferably, the dianhydride includes any one or a combination of at least two of pyromellitic anhydride, biphenyltetracarboxylic dianhydride or hexafluorodianhydride, more preferably pyromellitic anhydride;

[0065] Preferably, the solvent includes N,N dimethylformamide and / or N,N dimethylacetamide;

[0066] As an optional embodiment of the present invention, the molar ratio of diamine and dianhydride is (0.98-1.02):(0.97-1.03). Typical but non-limiting molar ratios are 0.98:0.97, 0...

Embodiment 1

[0085] The present embodiment provides a method for preparing a composite integrated separator for a lithium-sulfur battery, comprising the following steps:

[0086] (a) Provide polyamic acid spinning solution: add 1.5 g of 4,4'-diaminodiphenyl ether to 14.6 g of N,N-dimethylformamide to dissolve, and then in an ice-water bath, add 1.6 g of pyromellitic anhydride was added to the reaction system, and after 6 hours of reaction, a polyamic acid spinning solution was obtained.

[0087] Put the polyamic acid spinning solution into a 10mL syringe, assemble the syringe with a metal needle, and fix it on the high-voltage electrospinning machine. 18kV, the injection speed is 15μL / min, the receiver speed is 30r / min, and the spinning time is about 2h, to obtain a polyamic acid fiber membrane with a thickness of 170μm;

[0088] (b) The polyamic acid fiber membrane is thermally imidized in the air, that is, the temperature is increased in stages, and the heating rate is 2 °C / min. The te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com