A kind of preparation method of high-efficiency infrared thermo-optic modulator

A thermo-optic modulator and high-efficiency technology, applied in the field of modern optics, can solve the problems of complex structure, cumbersome manufacturing process, and low efficiency of the optical modulator, and achieve the effects of high electron mobility, high efficiency, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

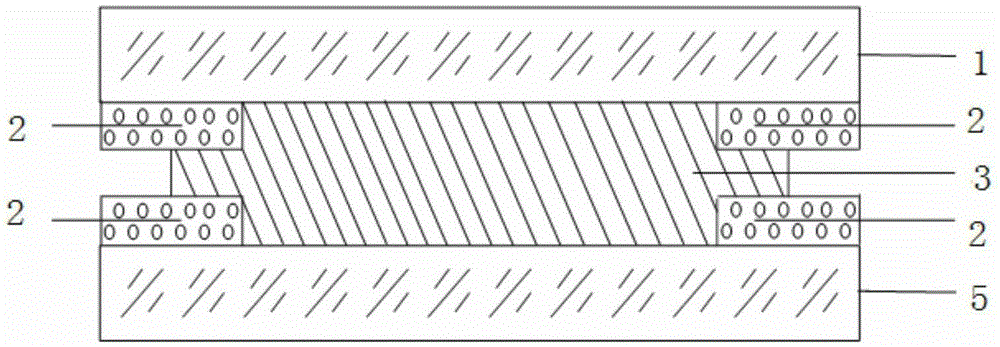

[0021] In order to make the technical solution of the present invention more clearly understood, the present invention will now be described in detail in conjunction with the accompanying drawings.

[0022] Such as figure 1 As shown, the high-efficiency infrared light modulator designed by the present invention is packaged by an upper zinc selenide substrate 1, four graphene electrodes 2, a tungsten-doped vanadium dioxide film 3, and a lower zinc selenide substrate 5.

[0023] The preparation method of the mid-infrared light modulator of the present invention, its steps are as follows:

[0024] Zinc selenide substrate cleaning: cleaning with an ultrasonic cleaner, the ultrasonic frequency is 60-80KHz, cleaning with deionized water, absolute ethanol, acetone, and absolute ethanol for 3-5 minutes, and then cleaning twice with deionized water, each 5 minutes each time. Then take out the substrate, dry the water droplets on the surface with an ear washing ball, put it into an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com