Additive for 4 micron carrier-free electrolytic copper foil, preparation method and application thereof

A technology of electrolytic copper foil and additives, applied in the direction of electrolysis, electroforming, etc., to achieve the effect of increasing crystal density, high tensile strength, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

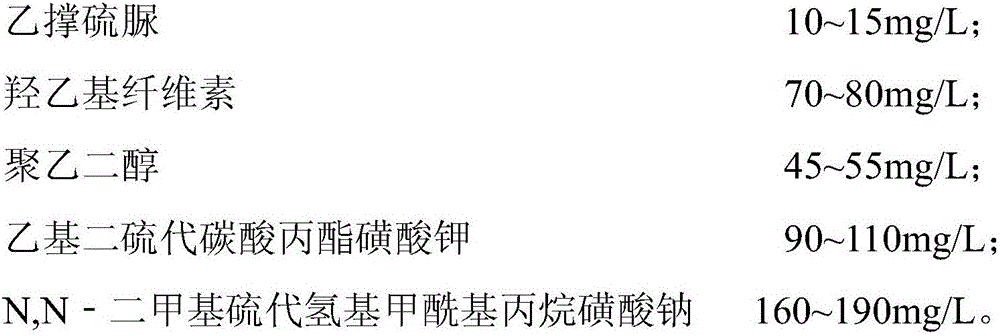

[0028] Embodiment 1: The additive for the 4 micron carrier-free electrolytic copper foil provided in this embodiment includes the following raw material components in weight ratio:

[0029] Ethylenethiourea 10~15mg / L;

[0030] Hydroxyethyl cellulose 70~80mg / L;

[0031] Polyethylene glycol 45~55mg / L;

[0032] Potassium ethyldithiopropylcarbonate sulfonate 90~110mg / L;

[0033] N. Sodium N-dimethylthiohydrogenmethylacylpropane sulfonate 160~190mg / L.

[0034] Preferably, the ethylene thiourea, hydroxyethyl cellulose, polyethylene glycol, potassium ethyl dithiopropyl carbonate sulfonate, N.N-dimethylthiohydrogen methyl acyl propane sodium The weight ratio is 12.5:75:50:100:175 mg / L. That is, in every liter of additives, the ethylenethiourea, hydroxyethyl cellulose, polyethylene glycol, potassium ethyldithiocarbonate sulfonate, N.N-dimethylthiohydrogen methylacyl propane sulfonate The weight ratio of sodium bicarbonate is 12.5:75:50:100:175mg.

[0035] The preparation method o...

Embodiment 2

[0042] Embodiment 2: The additive for a 4 micron carrier-free electrolytic copper foil provided in this embodiment includes the raw material components in the following weight ratio:

[0043] Ethylenethiourea 15mg / L;

[0044] Hydroxyethyl cellulose 80mg / L;

[0045] Polyethylene glycol 55mg / L;

[0046] Potassium ethyl dithiopropyl carbonate sulfonate 110mg / L;

[0047] N. Sodium N-dimethylthiohydrogenmethylacylpropane sulfonate 190mg / L.

[0048] The preparation method of the additive for the 4 micron carrier-free electrolytic copper foil comprises the following steps:

[0049] (1) Weigh each raw material component according to the following weight ratio: 15 mg of ethylene thiourea; 80 mg of hydroxyethyl cellulose; 55 mg of polyethylene glycol; 110 mg of potassium ethyl dithiopropyl carbonate sulfonate; Sodium thiohydromethylacylpropane sulfonate 190mg;

[0050] (2) The ethylene thiourea, hydroxyethyl cellulose, polyethylene glycol, potassium propyl dithiocarbonate sulfonate...

Embodiment 3

[0052] Embodiment 3: A kind of additive for 4 micron unsupported electrolytic copper foil provided in this embodiment, it comprises the raw material component of following weight ratio:

[0053] Ethylenethiourea 10mg / L;

[0054] Hydroxyethyl cellulose 70mg / L;

[0055] Polyethylene glycol 45mg / L;

[0056] Potassium ethyl dithiopropyl carbonate sulfonate 90mg / L;

[0057] N. Sodium N-dimethylthiohydrogenmethylacylpropane sulfonate 160mg / L.

[0058] The preparation method of the additive for the 4 micron carrier-free electrolytic copper foil comprises the following steps:

[0059] (1) Weigh each raw material component according to the following weight ratio: ethylene thiourea 10 mg; hydroxyethyl cellulose 70 mg; polyethylene glycol 45 mg; Sodium thiohydromethylacylpropane sulfonate 160mg;

[0060] (2) The ethylene thiourea, hydroxyethyl cellulose, polyethylene glycol, potassium propyl dithiocarbonate sulfonate, and N.N-dimethylthiohydrogen methyl that were weighed in step (1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com