Ink for active energy ray-curable inkjet recording

A technology of active energy ray and inkjet recording, which can be used in ink, applications, household appliances, etc., and can solve the problem that there is no record of the effect of color mixing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

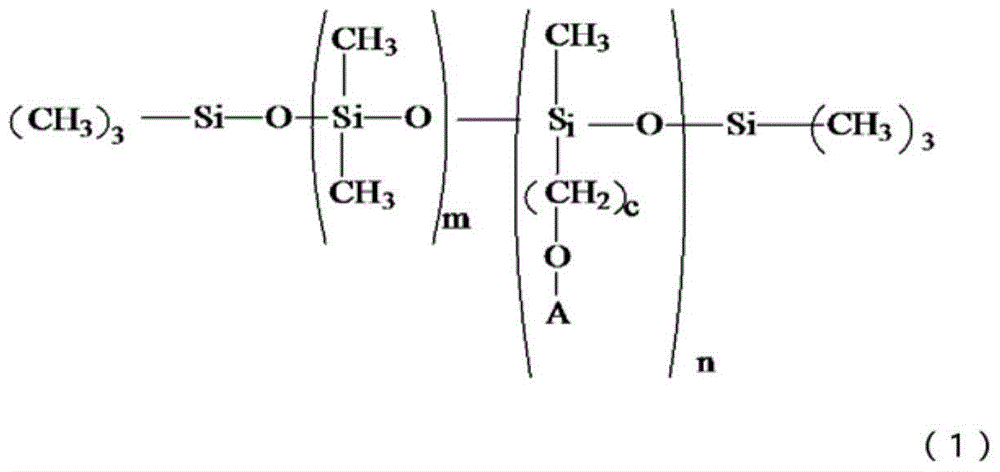

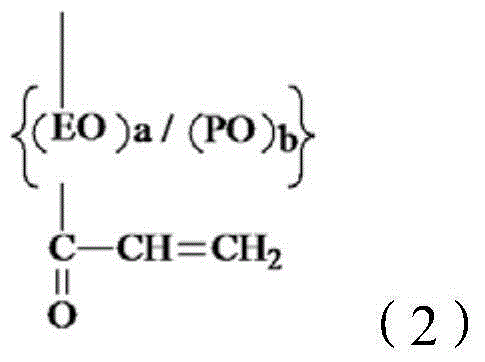

[0115] Add 13.4 parts of dipropylene glycol diacrylate, 6.0 parts of pentaerythritol hexaacrylate, 30.5 parts of 2-(2,-ethyleneoxyethoxy)ethyl acrylate, and 9.0 parts of isooctyl acrylate, and use it as a photopolymerization initiator at 60°C 3.0 parts of IRGACURE819, 4.0 parts of LUCIRIN TPO, 2.5 parts of DAROCURE DR1173 and 1.0 parts of IRGACURE907 were heated and dissolved. Furthermore, 24.0 parts of high-concentration yellow dispersion liquids and 0.3 parts of Tego Rad2300 and 1.0 parts of Tego Rad2100 which are two types of silicone polyether acrylates which were prepared by the adjustment of high-concentration yellow dispersion liquid were added to this solution. Further add 2.5 parts of 2,4-diethylthioxanthone as a sensitizer, 2.5 parts of dimethylaminobenzoic acid as a sensitizer, 0.1 part of 2,5-di-tert-butyl hydroquinone as a polymerization inhibitor, 0.2 parts Modified silicone oil. These substances were added and mixed sufficiently, and then filtered through a 1.2...

Embodiment 2~6、 comparative example 1~12)

[0117] In the same manner as in Example 1, the active energy ray-curable inkjet recording ink compositions of Examples 2 to 6 and Comparative Examples 1 to 12 were prepared according to the formulations described in Tables 1 and 2. The prepared active energy ray-curable inkjet recording ink compositions of Examples 2 to 6 are referred to as Naenta1, Cyan1, Black1, Magenta2, and Cyan2. Further, the active energy ray-curable inkjet recording ink compositions of Comparative Examples 1 to 12 are referred to as Yellow3, Magenta3, Cyan3, Black3, Yellow4, Magenta4, Cyan4, Black4, Magenta5, Cyan5, Magenta6, and Cyan6.

[0118] [Table 1]

[0119] (Table 1)

[0120]

[0121] [Table 2]

[0122] (Table 2)

[0123]

[0124] The names described in the columns of each raw material in Table 1 and Table 2 are the names that are considered to be the most commonly used among product names and chemical substance names.

[0125] The chemical substance names, trade names, and manufacturer...

Embodiment 7-1)

[0186] Using Yellow1 and Magenta1 in the ink set 1 composed of Yellow1, Magenta1, Cyan1, and Black1 produced in Examples 1 to 4, the occurrence of color mixing when they are ejected to the recording medium in a close manner is carried out as follows Evaluation.

[0187] [Desktop evaluation of color mixing occurrence status (color mixing evaluation 1)]

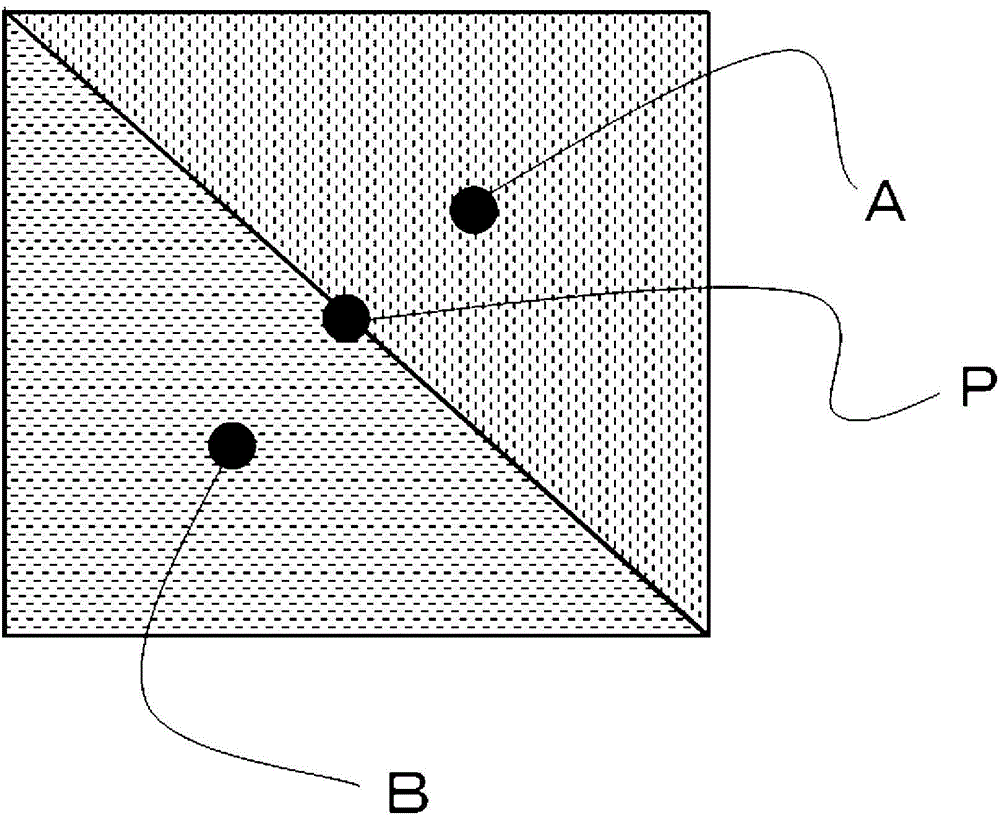

[0188] On a 5 cm × 5 cm PET film (Lumirror250E22, manufactured by Toray Co., Ltd.), using a micropipette, two inks of different colors selected from ink set 1 (for example, Yellow1 (Y1) and Magenta1 (M1) ) at the same time by dropping 50 μl at a constant distance of 1 cm from the position that is the rotation center of the spin coater. At this time, the two dropping positions are aligned with the center of rotation. Using a spin coater at a constant rotation speed of 6,000 rotations for 10 seconds, the midpoint of the two dripping points of the ink was used as the center of rotation to spread the coating film. Thus, if figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluorescence wavelength | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com