Heat recovery method and system for recovering energy in water-rich biomass

A biomass and heat recovery technology, applied in the methods of chemically changing substances by atmospheric pressure, biofuels, chemical instruments and methods, etc. and replacement costs, etc., to achieve enhanced safety and stability, reduced operating costs, and good energy-saving and emission-reduction effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

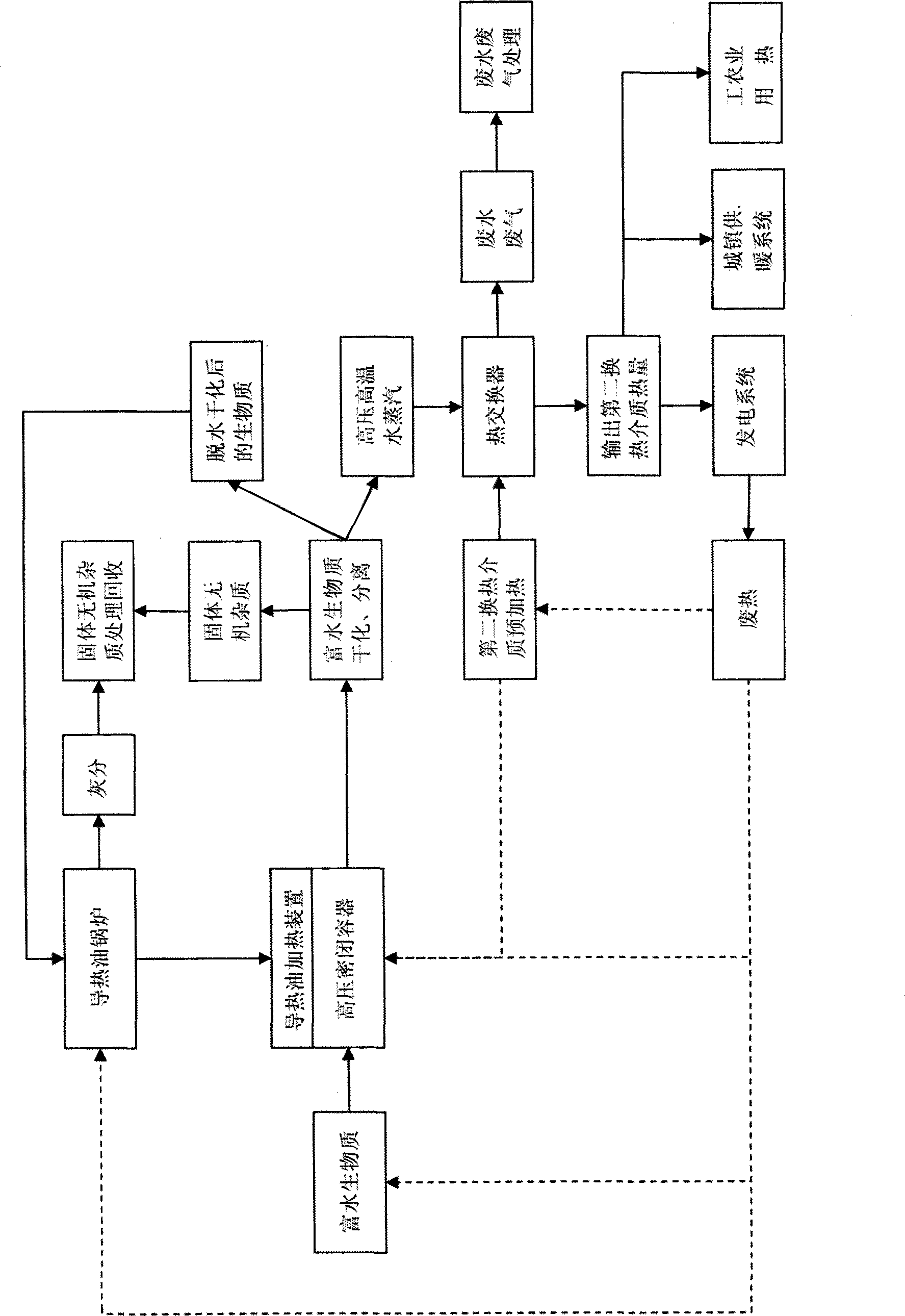

[0090] Such as figure 1 Shown, a kind of heat recovery method that reclaims the energy in the water-rich biomass, comprises the following steps:

[0091] Step 1): put the water-rich biomass with a moisture content of <99.9% into a high-pressure airtight container, and heat the high-pressure airtight container;

[0092] Step 2): In the first-level heating process, the temperature in the high-pressure airtight container is controlled at 180°C and the pressure is at 1.0MPa, so that the water-rich biomass is in a liquefied state, and most of the biomass components do not undergo chemical decomposition, and are in the state of a mixed aqueous solution. Keep the temperature and pressure in the high-pressure airtight container constant and let it stand for 15 minutes to separate the biomass and solid inorganic impurities in the water-rich biomass. Due to the difference in specific gravity, the heavier solid inorganic impurities precipitate to the bottom of the high-pressure airtight ...

Embodiment 2

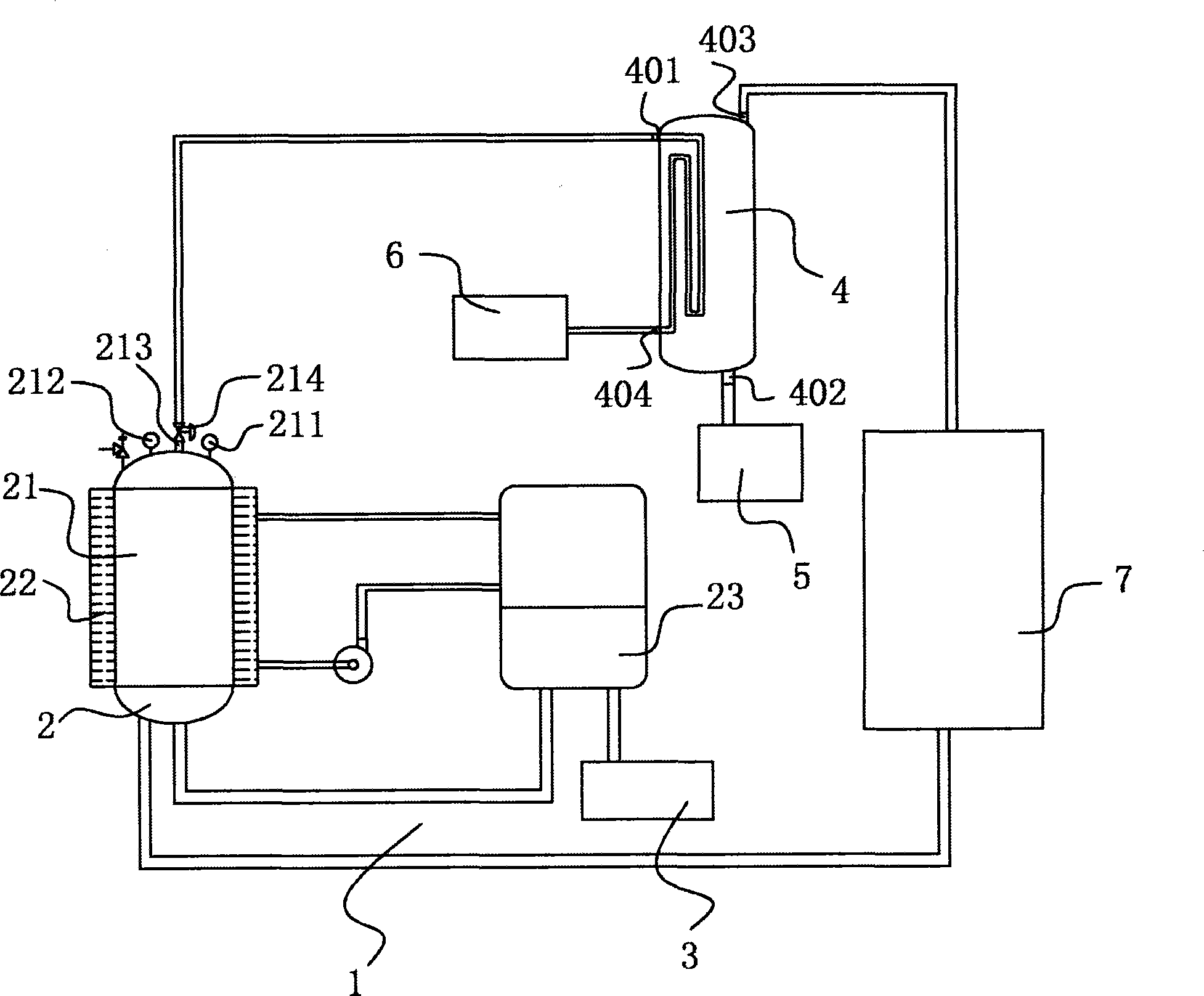

[0142] The second object of the present invention is to provide a system for recovering energy in water-rich biomass. As shown in 2, the system 1 for recovering energy in water-rich biomass includes drying equipment 2, ash disposal equipment 3, thermal The exchanger 4 is used as a heat collection and recovery device for high-temperature and high-pressure water vapor, a clean room temperature water supply device 5 , a waste water and waste gas treatment device 6 and a steam turbine power generation system 7 .

[0143] The drying equipment 2 is composed of a high-pressure airtight container 21, an oil bath heating jacket 22 and a heat conduction oil boiler 23; the heat conduction oil boiler 23 is connected to the oil bath heating jacket 22 through pipelines; the high pressure airtight container 21 is placed in an oil bath heating In the jacket 22; a pressure gauge 211, a thermometer 212, and a steam output port 213 are installed on the high-pressure airtight container 21, and a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com