A magnetic anisotropic janus microsphere with controllable particle size and shape, its preparation method and the microfluidic control device used therein

A technology of magnetic anisotropy and magnetic particles, which is used in the preparation of microspheres, chemical instruments and methods, microcapsule preparations, etc. The problems of particle size and morphology are difficult to achieve the effect of broadening the application, low cost and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

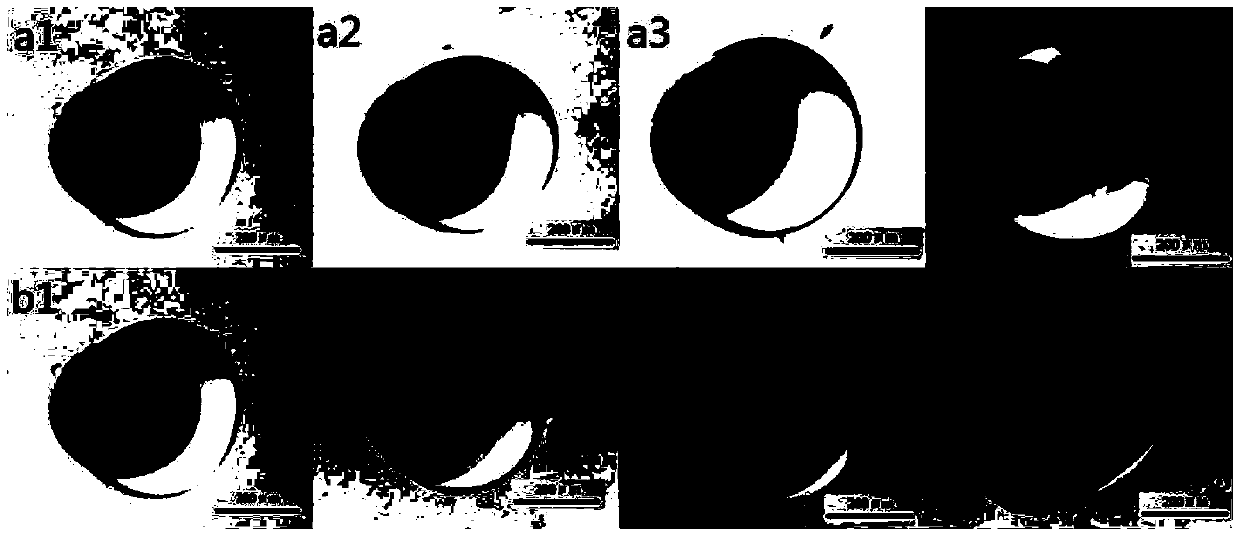

[0050] This embodiment prepares magnetically heterogeneous Janus microspheres according to the following steps:

[0051] a. Preparation of magnetic particles: 1.68g of ferrous sulfate heptahydrate was added to 60mL of deionized water, 2.43g of ferric chloride hexahydrate was added to 15mL of deionized water, the two were stirred and dissolved by magnetic force, and then mixed into a beaker. Place the beaker in a 60°C water bath and heat it. With mechanical stirring and at a temperature of 60°C, use a sprayer to spray 2mol / L sodium hydroxide solution into the mixed solution until the pH of the mixed solution reaches 11-12. Keep the mechanical stirring at 60°C. Temperature reaction for 1 hour to obtain a magnetic particle suspension solution; centrifuge the magnetic particle suspension solution to obtain a magnetic particle precipitate, successively wash the magnetic particle precipitate with deionized water, ethanol and ethyl acetate for several times, and then dry it at 90°C D...

Embodiment 2

[0057] This embodiment prepares magnetically heterogeneous Janus microspheres according to the following steps:

[0058] a. Preparation of magnetic particles: Add 1.68g of ferrous sulfate heptahydrate into 60mL of deionized water, add 2.43g of ferric chloride hexahydrate into 15mL of deionized water, stir and dissolve the two, and mix them into a beaker , place the beaker in a 60°C water bath and heat it. With mechanical stirring and at a temperature of 60°C, use a sprayer to spray 2mol / L sodium hydroxide solution into the mixed solution until the pH of the mixed solution reaches 11-12. Keep mechanical stirring and 60 ℃ temperature reaction for 1 hour to obtain a magnetic particle suspension solution; centrifuge the magnetic particle suspension solution to obtain a magnetic particle precipitate, successively wash the magnetic particle precipitate with deionized water, ethanol and ethyl acetate for several times, and then 90°C Dry under ambient conditions for 2 hours to obtain ...

Embodiment 3

[0066] This embodiment prepares magnetically heterogeneous Janus microspheres according to the following steps:

[0067] a. Preparation of magnetic particles: Add 1.68g of ferrous sulfate heptahydrate into 60mL of deionized water, add 2.43g of ferric chloride hexahydrate into 15mL of deionized water, stir and dissolve the two, and mix them into a beaker , place the beaker in a 60°C water bath and heat it. With mechanical stirring and at a temperature of 60°C, use a sprayer to spray 2mol / L sodium hydroxide solution into the mixed solution until the pH of the mixed solution reaches 11-12. Keep mechanical stirring and 60°C. ℃ temperature reaction for 1 hour to obtain a magnetic particle suspension solution; centrifuge the magnetic particle suspension solution to obtain a magnetic particle precipitate, successively use deionized water, ethanol and ethyl acetate to wash the magnetic particle precipitate multiple times, and then 90°C Dry under ambient conditions for 2 hours to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com