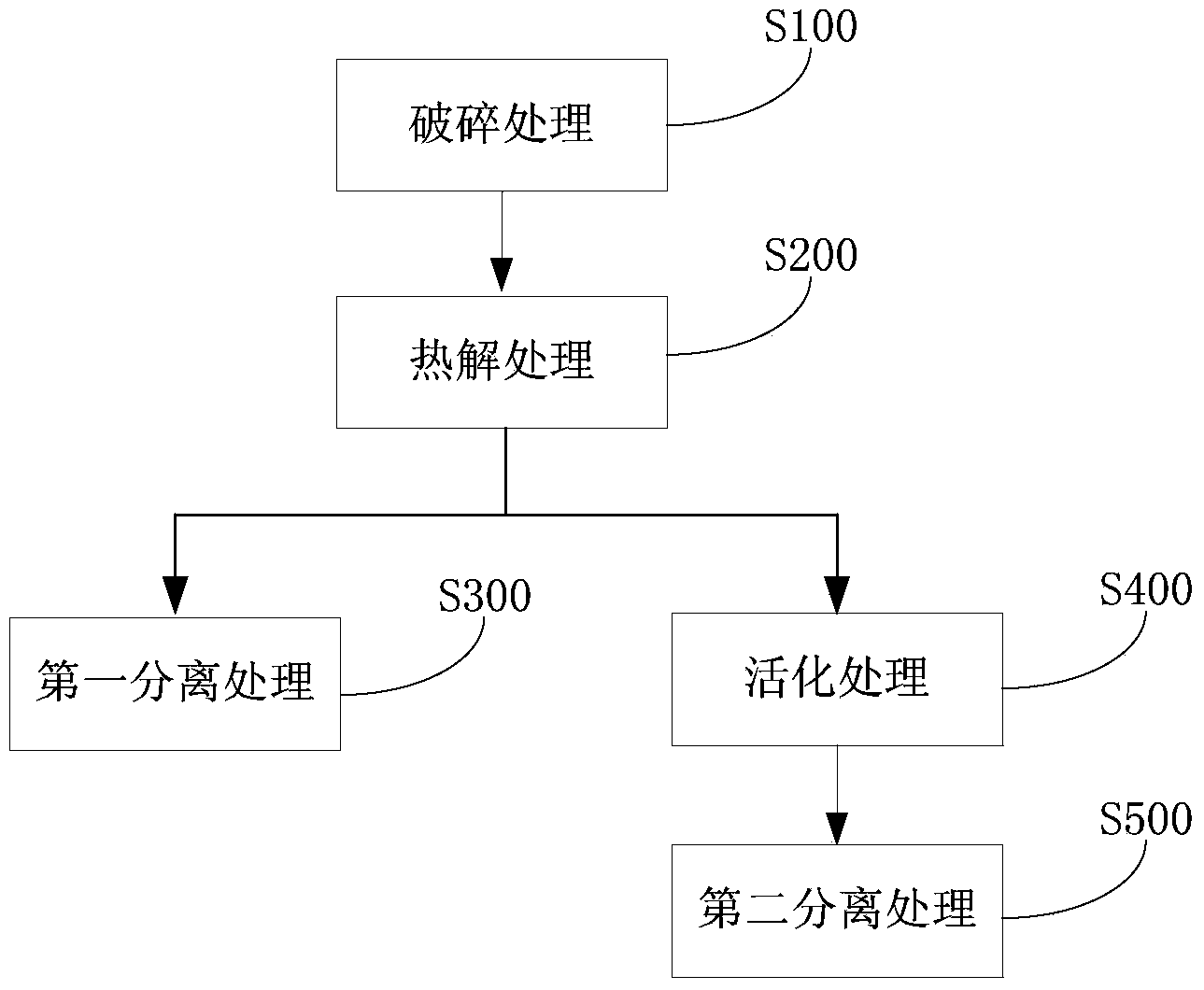

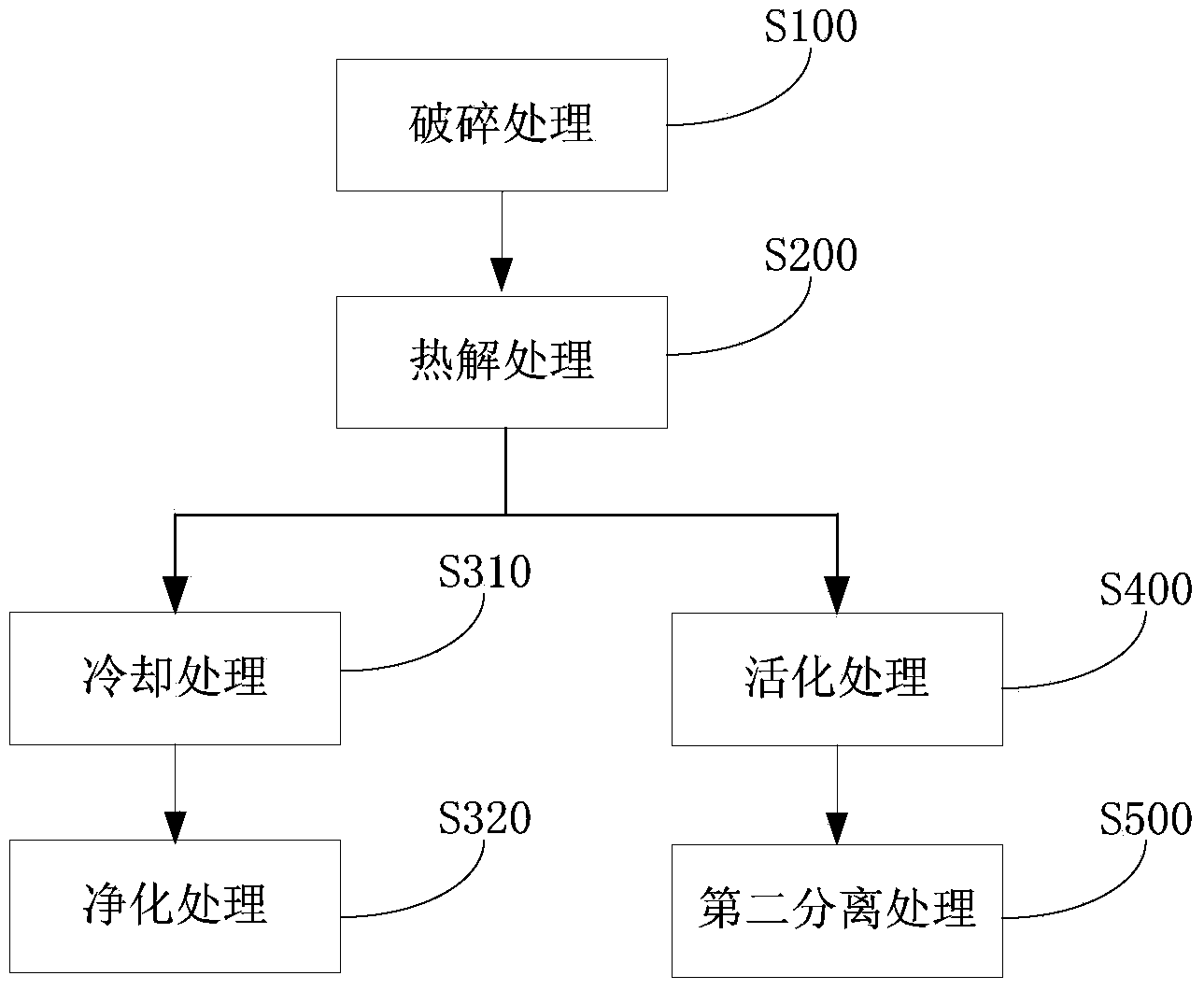

Method and system for treating circuit board

A circuit board and activation treatment technology, applied in the chemical industry, can solve the problems of no recycling, small processing capacity, waste of resources and environment, etc., and achieve the effects of maximizing utilization, reducing processing costs, and facilitating separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

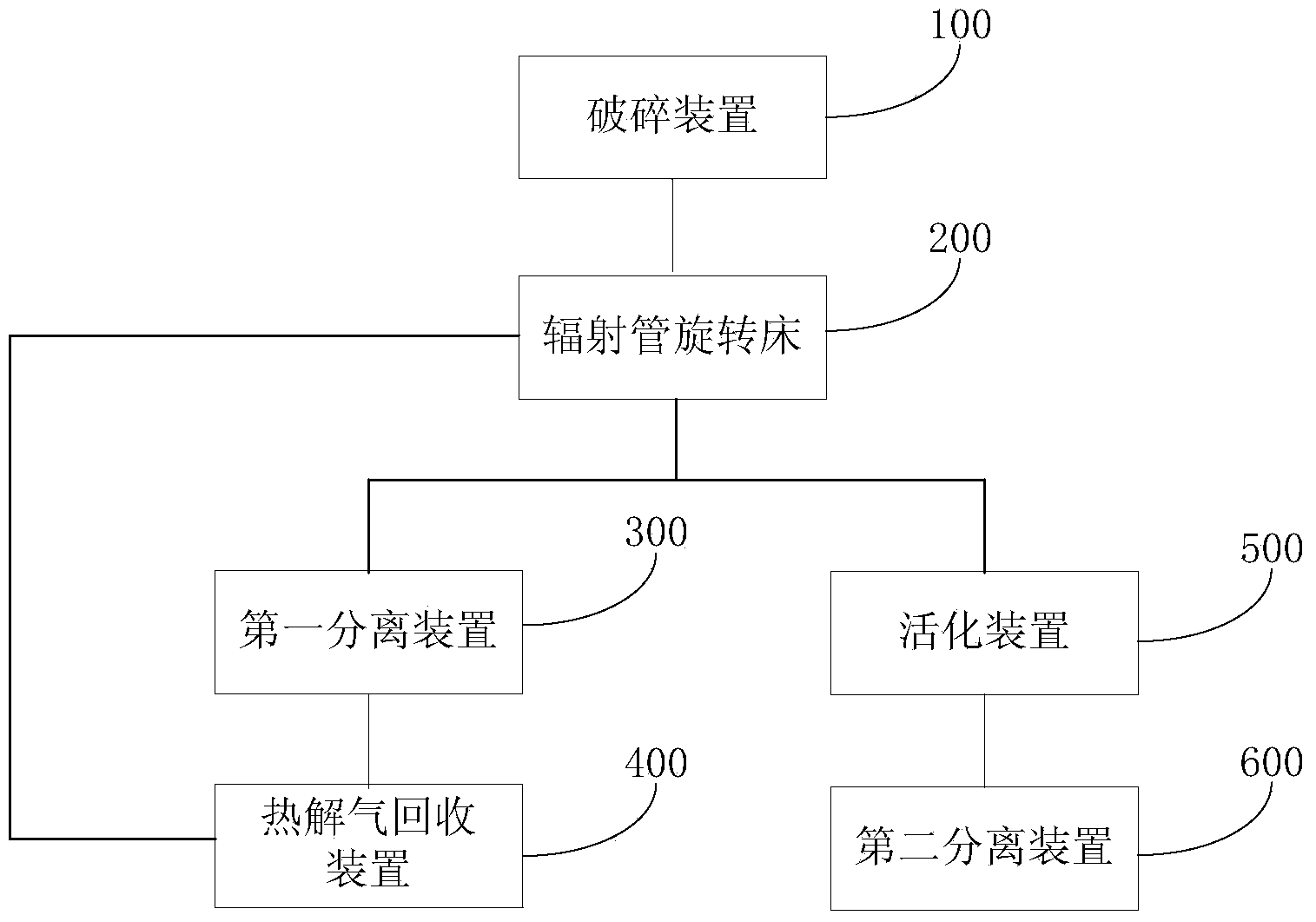

[0075] Use the waste circuit boards that have been disassembled with electrical components as raw materials, put them in a crusher for crushing, and crush them to a particle size of 5-20mm; evenly feed the crushed circuit board raw materials into the radiant tube rotary bed pyrolysis furnace During the rotation process, the material is gradually heated to 530°C, and the time for one rotation is set to 2.5 hours. After the pyrolysis reaction is complete, a high-temperature oil gas and solid mixture (accounting for 64wt% of the raw material) is obtained, of which , the high-temperature oil and gas are collected through multiple oil-gas pipelines installed on the top of the pyrolysis furnace, and the collected high-temperature oil and gas are cooled to obtain pyrolysis oil (accounting for 20wt% of the raw material) and pyrolysis gas (accounting for 16wt% of the raw material) , and use alkaline substances to absorb acidic and harmful gases such as halogens in the pyrolysis gas to o...

Embodiment 2

[0077] Use the waste circuit boards that have been disassembled with electrical components as raw materials, put them in a crusher for crushing, and crush them to a particle size of 5-20mm; evenly feed the crushed circuit board raw materials into the radiant tube rotary bed pyrolysis furnace During the rotation process, the material is gradually heated to 770°C, and the rotation time is set to 1.5 hours. After the pyrolysis reaction is complete, a high-temperature oil gas and solid mixture (accounting for 60wt% of the raw material) is obtained, of which , high-temperature oil and gas are collected through multiple oil-gas pipelines installed on the top of the pyrolysis furnace, and the collected high-temperature oil and gas are cooled to obtain pyrolysis oil (accounting for 17wt% of the raw material) and pyrolysis gas (accounting for 23wt% of the raw material) , and use alkaline substances to absorb acidic and harmful gases such as halogens in the pyrolysis gas to obtain pure p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com