Method of preparing high F-value collagen peptide by hydrolyzing anglerfish fishskins

A collagen peptide and collagen protein technology, which is applied in the field of hydrolyzing anglerfish skin to prepare high F-value collagen peptides, can solve the problems of ineffective use of anglerfish skin waste, lack of preparation of high-F value fish collagen peptides, etc., and achieve effective Good for human body absorption, relatively small molecule, high value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

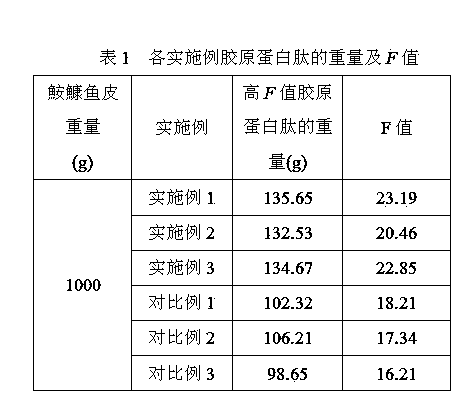

Embodiment 1

[0030] Take 1000 g of washed anglerfish skin and cut it into pieces with a length and width of about 2 cm×2 cm with scissors. Add 25L of 4.5% NaOH solution to the anglerfish skin fragments, soak for 24 h, take out, and then wash with water until the pH is neutral. Add 35 L of 9% n-butanol solution to the fish skin, stir for 28 h, take it out, wash with water and drain. Crush the drained anglerfish skin fragments, add citric acid solution with a mass fraction of 4% according to the ratio of fish skin and citric acid solution to 1:4, heat to 55°C, and continuously stir to extract After 6 h, the crude collagen extract was obtained after filtration. Then the crude collagen extract was put into an insulating bag, and subjected to high-voltage pulse electric field treatment for 0.5h. Set the pulse time of the high-voltage pulsed electric field treatment as 1s, the pulse frequency as 30Hz, and the electric field intensity as 25kV / cm. After taking it out, add 1% pepsin to the crude...

Embodiment 2

[0032]Take 1000 g of washed anglerfish skin and cut it into pieces with a length and width of about 2 cm×2 cm with scissors. Add 25L of 2.5% NaOH solution to the anglerfish skin fragments, soak them for 30 h, take them out, and then wash them with water until the pH is neutral. Add 35 L of 9% n-butanol solution to the fish skin, stir for 20 h, take it out, wash with water and drain. The drained anglerfish skin fragments were mashed, and the ratio of fish skin to acetic acid solution was 1:7, then 1% acetic acid solution was added, heated to 65°C, and extracted with constant stirring for 7 h , to obtain crude collagen extract after filtration. Then the crude collagen extract was put into an insulating bag, and subjected to high-voltage pulse electric field treatment for 1 hour. Set the pulse time of the high-voltage pulsed electric field treatment as 1s, the pulse frequency as 40Hz, and the electric field intensity as 15kV / cm. After taking it out, add 2% pepsin to the crude ...

Embodiment 3

[0034] Take 1000 g of washed anglerfish skin and cut it into pieces with a length and width of about 2 cm×2 cm with scissors. Add 25L of 5.5% NaOH solution to the anglerfish skin fragments, soak for 28 hours, take it out, and then wash with water until the pH is neutral. Then add 35 L of 9% n-butanol solution to the fish skin, take it out after stirring for 25 hours, wash with water and drain. Crush the drained anglerfish skin fragments, add citric acid solution with a mass fraction of 2% according to the ratio of fish skin and citric acid solution to 1:5, heat to 90°C, and continuously stir to extract After 5h, the crude collagen extract was obtained after filtration. Then the crude collagen extract was put into an insulating bag, and subjected to high-voltage pulse electric field treatment for 0.8h. Set the pulse time of the high-voltage pulsed electric field treatment as 1s, the pulse frequency as 35Hz, and the electric field intensity as 20kV / cm. After taking it out, ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com