Titanium-based amorphous /pure titanium double-continuous phase composite material and preparation method thereof

A composite material and dual continuous phase technology, applied in the field of titanium-based amorphous composite materials, can solve the problems of macroscopic brittleness of titanium-based amorphous alloys, and achieve the effects of improving specific strength, reducing density and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Prepare 100g of titanium-based master alloy by using arc melting equipment, the composition is: Ti 34.3 Zr 31.5 Ni 5.5 Cu 5 be 23.7 , Ti 33.6 Zr 30.9 Ni 5.4 Cu 7 be 23.1 , Ti 32.8 Zr 30.2 Ni 5.3 Cu 9 be 22.7 and Ti 32.。1 Zr 29.5 Ni 5.2 Cu 11 be 22.2 (atomic percent).

Embodiment 2

[0054] When Ti 34.3 Zr 31.5 Ni 5.5 Cu 5 be 23.7 (at.%) alloy and 60% porosity porous titanium framework (pore size is 100~200μm) composite, made of 10mm × 30mm × 70mm composite plate, its microstructure is as follows figure 1 As shown, no defects such as holes are formed at the interface, indicating that the Ti-based amorphous alloy is completely filled into the titanium skeleton. Compression test (eg Figure 4 shown) shows that the composite has high strength (compressive fracture strength 1650 MPa) and high plasticity (compressive plastic strain ~20%).

Embodiment 3

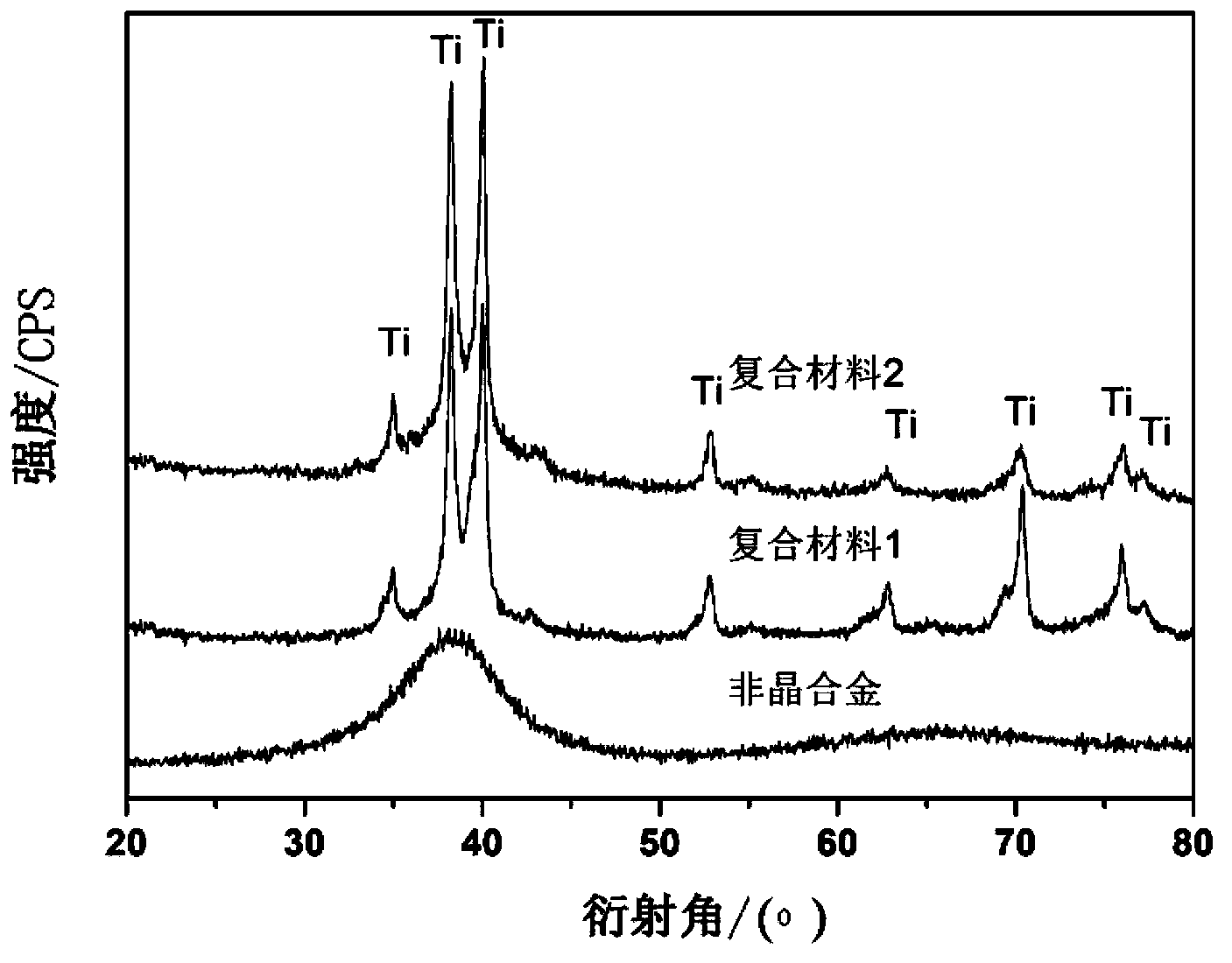

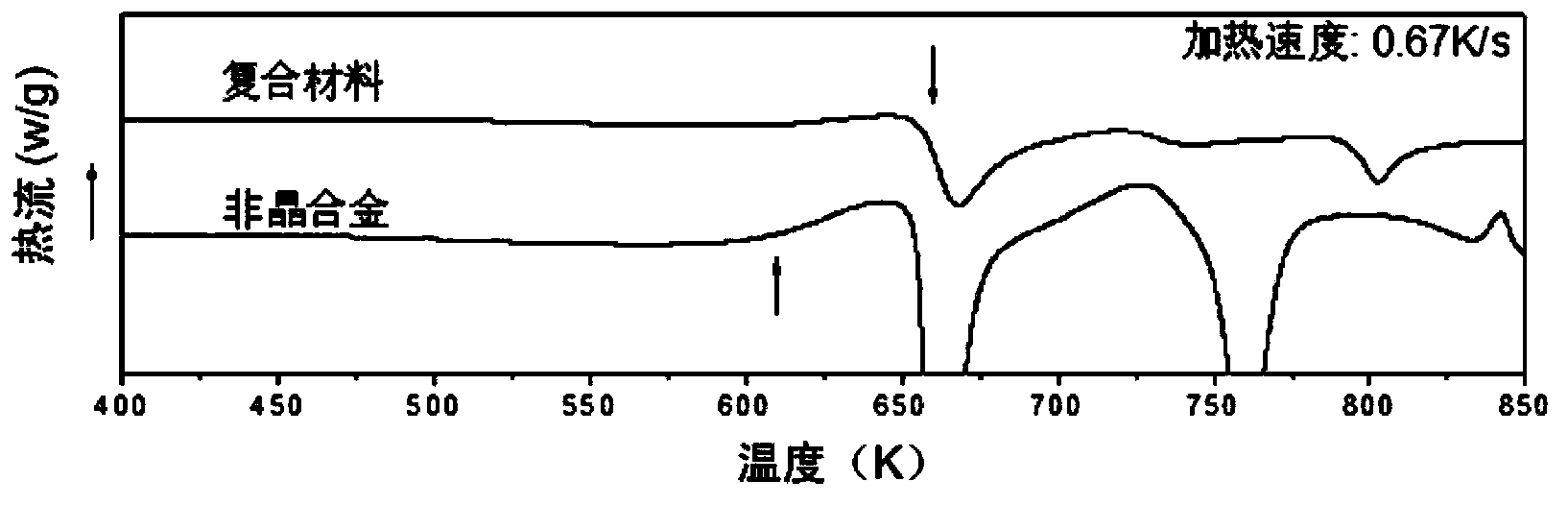

[0056] When Ti 32.8 Zr 30.2 Ni 5.3 Cu 9 be 22.7 (at.%) alloy and 40% porosity porous titanium framework (pore size 50~200μm) composite, the X-ray diffraction pattern of the composite material is as follows figure 2 as shown, figure 2 Composite material 1 and composite material 2 correspond to the central part and edge part of the composite material respectively. It can be seen from the figure that the composite material is only composed of amorphous phase and α-Ti. The central part of the composite material is sampled for DSC detection, such as image 3 As shown in the figure, the pure Ti is correspondingly given 32.8 Zr 30.2 Ni 5.3 Cu 9 be 22.7 (at.%) amorphous alloy curve as a comparison, it is found that the amorphous phase and pure Ti in the composite material 32.8 Zr 30.2 Ni 5.3 Cu 9 be 22.7 (at.%) amorphous alloys exhibited similar thermodynamic behavior, indicating that the composition of the amorphous phase in the as-prepared materials did not change s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com