Nutritional rice oil and production method thereof

A rice oil and nutrition enhancement technology, applied in the production of fat oil/fat, production of fat, edible oil/fat, etc., can solve the problem of large loss of nutrients, improve the vacuum degree of the system, reduce the loss of fat-soluble nutrients, The effect of improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

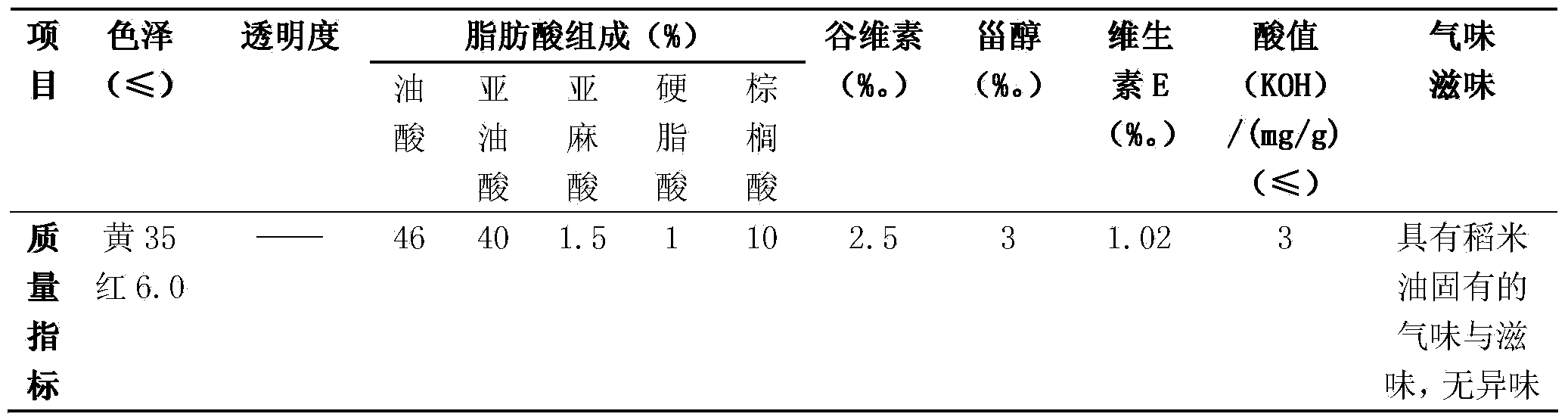

Embodiment 1

[0050] After the rice bran (including rice germ) produced after rice processing is screened, destoned and demagnetized, the clean oil is extruded with a twin-screw extruder to control the water content of the oil to 13% and the screw speed The temperature is 150r / min, the barrel temperature is 150°C, the size of the extruded particles is controlled to be about 1cm×0.5cm×0.5cm, and the stabilized rice bran is obtained after drying to a water content of 4-6%. Soak the stabilized rice bran in 6 times its volume of No. 6 extraction solvent oil (a commercially available vegetable oil extraction solvent, see National Standard of the People's Republic of China, Vegetable Oil Extraction Solvent, Standard No. GB16629-2008, Chinese Standard Publishing Press, September 2008, Beijing), leaching at 50°C for 2 hours, and evaporating the solvent to obtain crude oil. After the solid impurities in the crude oil were removed by plate and frame filtration, phospholipase A 1 The role of removing...

Embodiment 2

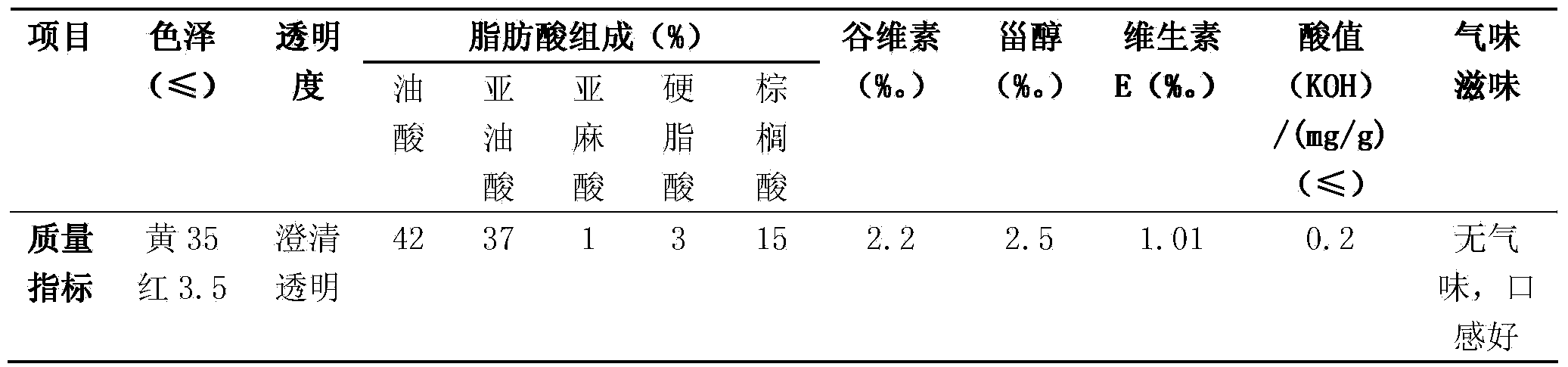

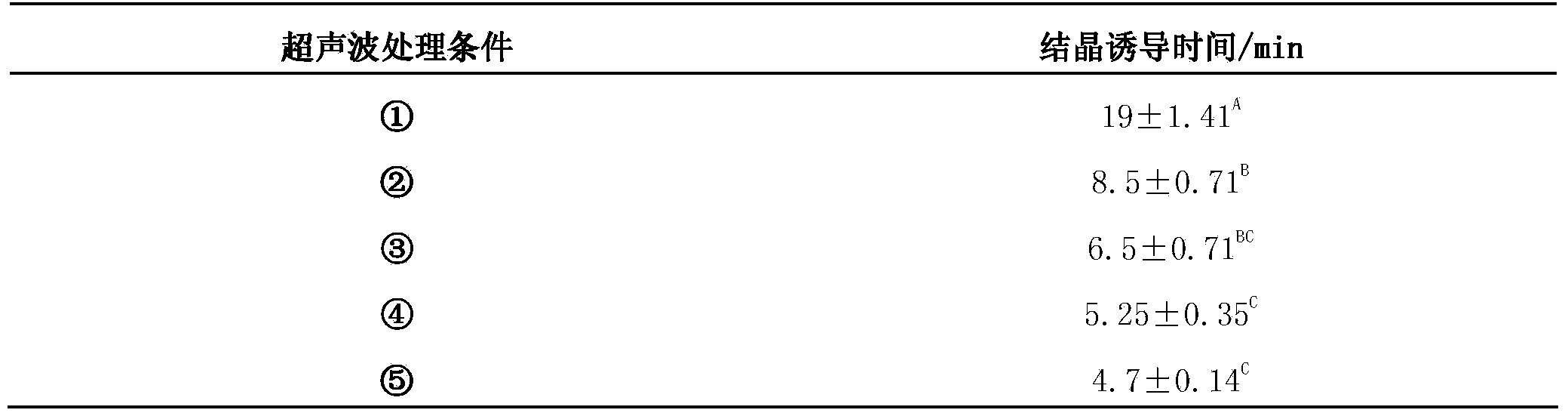

[0055] After the refined rice oil 1 was obtained according to the method of Example 1, activated diatomite and 1% activated carbon were added to the rice oil quality of 4%, and the pressure of the system was maintained at 6kPa. After reacting for 30 minutes at 110°C, decolorized oil 2 was obtained. . The decolorized oil 2 is pumped into the falling film evaporator to circulate for deodorization treatment, the system pressure is maintained at 0.3kPa, and the reaction temperature is 230°C. Add 4% of its mass of activated diatomite and 1% of activated carbon to the deodorized oil, maintain the system pressure at 6kPa, and the temperature at 110°C. After reacting for 30 minutes, separate the oil from the filter medium (activated diatomite, activated carbon), The oil was pre-cooled to 30°C, and ultrasonic cell breaker (VOSHIN96-IIL, Wuxi Woxin Instrument Co., Ltd.) was used to perform ultrasonic intermittent treatment on it. The action mode was 5s-intermittent 5s, the action time w...

Embodiment 3

[0060] According to Example 1 and Example 2, nutrient-enhanced rice oil was obtained, and 3 kg of nutrient-enhanced rice oil was heated and sterilized at 80° C. for 20 minutes to obtain sterilized enhanced rice oil; 0.4 kg of glycerol was added to 1.2 kg of purified water at 80° C. , stir well, put in 1kg of edible gelatin after the temperature is lower than 70°C, continue stirring for 1 hour, vacuum degassing for 30 minutes, and obtain gelatin liquid after filtration; use RJWJ-100II soft capsule manufacturing machine (product of Wuxi Zhongyi Pharmaceutical Machinery Co., Ltd.) To prepare rice oil soft capsules, set the rice oil soft capsules at 20°C and an environment with a relative air humidity of 40% for 2 hours, then dry them at 30°C and an environment with a relative air humidity of 20% for 5 hours, and control the soft capsules. When the water content of the shell reaches 6-8%, the finished nutritious rice oil soft capsule is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com