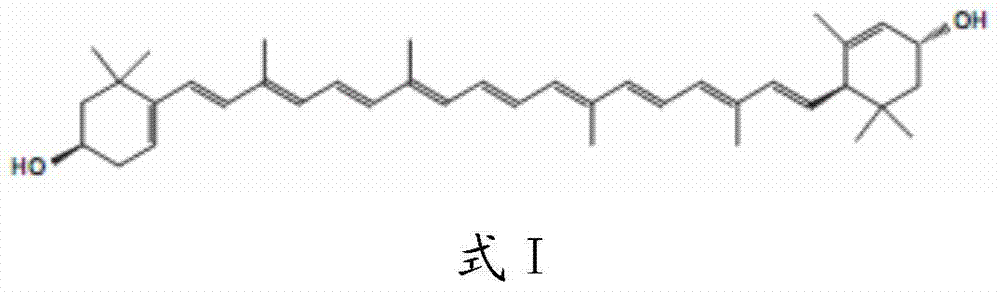

Lutein water-soluble powder and preparation method thereof

A technology of water-soluble powder and lutein, applied in the field of medicine, can solve the problems of cumbersome, low water-solubility, poor stability, etc., and achieve the effects of expanding the application range, uniform and lasting color, and high water-solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of lutein water-soluble powder, comprising the following steps:

[0031] (1) Mix 5g of lutein, 35g of polyvinylpyrrolidone K30, 10g of Tween-80 and 1g of α-tocopherol, and dissolve in 100g of ethyl acetate in a water bath at 50°C: absolute ethanol (w / w)=1: 1 in a mixed solvent;

[0032] (2) Spray-dry and evaporate the solvent to obtain lutein water-soluble powder. The spray drying condition is set to the air inlet flow rate of 48m 3 / h, spray pressure 2.5bar, liquid inlet pump speed 2.0r / s, control outlet air temperature to about 40°C.

Embodiment 2

[0034] A preparation method of lutein water-soluble powder, comprising the following steps:

[0035] (1) Mix 10g of 72% lutein, 100g of polyethylene glycol 2000, 20g of Span-80 and 2g of α-tocopherol, and dissolve in 200g of ethyl acetate in a water bath at 40°C: absolute ethanol (w / w) = 1:4 mixed solvent;

[0036] (2) Spray-dry and evaporate the solvent to obtain lutein water-soluble powder. The spray drying condition is set to the air inlet flow rate of 60m 3 / h, spray pressure 2.0bar, liquid inlet pump speed 1.8r / s, control outlet air temperature to about 45°C.

Embodiment 3

[0038] A preparation method of lutein water-soluble powder, comprising the following steps:

[0039] (1) Take 5g of 80% lutein, 75g of polyvinylpyrrolidone K30, 20g of Span-80 and 2g of ascorbic acid, and dissolve them in 150g of ethyl acetate: anhydrous ethanol (w / w) = 4:1 mixed solvent in a water bath at 50°C middle;

[0040] (2) Spray-dry and evaporate the solvent to obtain lutein water-soluble powder. The spray drying condition is set to the air inlet flow rate of 52m 3 / h, spray pressure 2.0bar, liquid inlet pump speed 2.5r / s, control outlet air temperature at 38°C-40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com