Method for preparing soft magnetic composite material through hot pressing

A composite material and soft magnetic technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of lower energy utilization rate, high price, eddy current loss, etc., to improve energy utilization rate, good The effect of magnetic properties and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

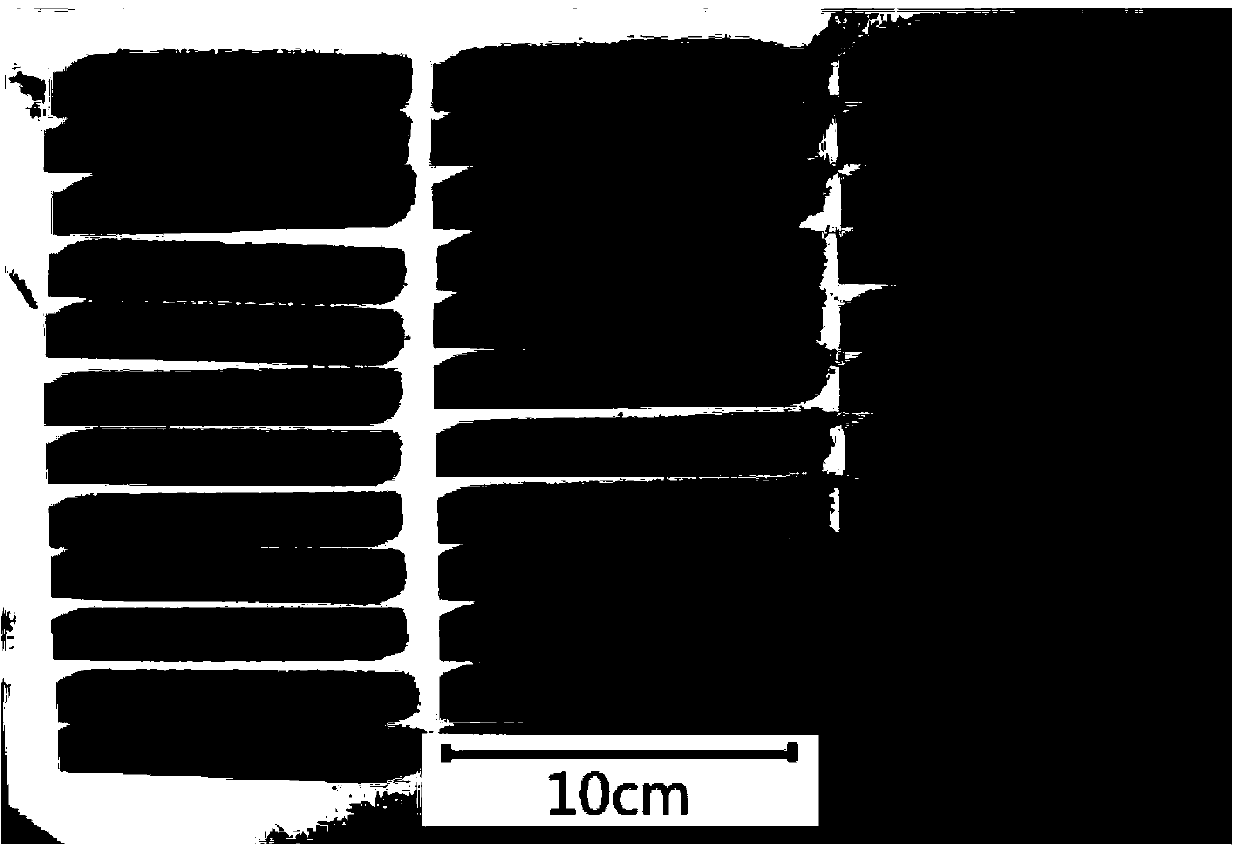

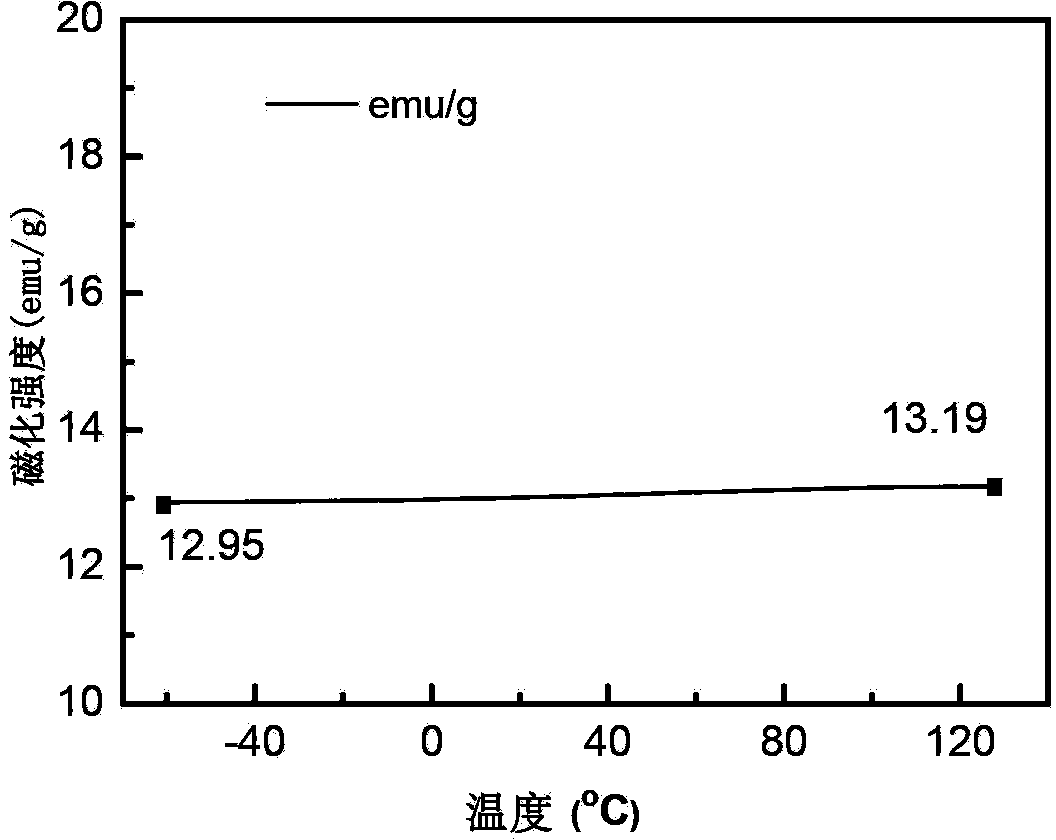

Image

Examples

Embodiment 1

[0036] 1) Weigh 100g of iron-silicon alloy particles with a particle size of 30μm into a 1000mL conical flask, add 500mL of medium (ethanol: distilled water=4:1) to the conical flask, and ultrasonically disperse for 15min;

[0037] Heat and stir the Erlenmeyer flask in a 60℃ water bath. After 30 minutes, add 0.2g of silane coupling agent KH-560, continue to heat and stir, and react for 4h~5h;

[0038] Take out the Erlenmeyer flask and separate it with a magnet. Place the magnet on the bottom of the beaker. After the magnetic particles quickly settle to the bottom, slowly pour out the solution, leaving only the magnetic particles, and then wash the separated magnetic nanoparticles with absolute ethanol for 5-6 times under the action of a magnetic field. Thoroughly wash away the unreacted silane coupling agent.

[0039] Place the washed magnetic particles in a vacuum drying oven for drying. After the drying is sufficient, the soft magnetic particles modified by the coupling agent are...

Embodiment 2

[0049] 1) Weigh 100g of ferrite particles with a particle size of 2μm and pour into a 1000mL conical flask, add 500mL of medium (ethanol:distilled water=4:2) to the conical flask, and ultrasonically disperse for 15min;

[0050] Heat and stir the Erlenmeyer flask in a 60°C water bath. After 30 minutes, add 0.1 g of silane coupling agent KH-550, continue to heat and stir, and react for 4 hours;

[0051] Take out the Erlenmeyer flask and separate it with a magnet. Place the magnet on the bottom of the beaker. After the magnetic particles quickly settle to the bottom, slowly pour out the solution, leaving only the magnetic particles, and then wash the separated magnetic nanoparticles 5 times with absolute ethanol under the action of a magnetic field to fully wash Remove unreacted silane coupling agent KH-550.

[0052] Place the washed magnetic particles in a vacuum drying oven for drying. After being dried sufficiently, the soft magnetic particles modified by the coupling agent are obt...

Embodiment 3

[0061] 1) Weigh 100g of iron-silicon alloy particles with a particle size of 200μm and pour it into a 1000mL conical flask, add 500mL of medium (ethanol: distilled water=4:1) to the conical flask, and ultrasonically disperse for 15min;

[0062] Heat and stir the conical flask in a water bath at 60°C. After 30 minutes, add 0.1 g of oleic acid, continue to heat and stir, and react for 4 hours;

[0063] Take out the Erlenmeyer flask and separate it with a magnet. Place the magnet on the bottom of the beaker. After the magnetic particles quickly settle to the bottom, slowly pour out the solution, leaving only the magnetic particles, and then wash the separated magnetic nanoparticles with absolute ethanol for 5-6 times under the action of a magnetic field. Thoroughly wash away unreacted oleic acid.

[0064] Place the washed magnetic particles in a vacuum drying oven for drying. After being dried sufficiently, grind to obtain soft magnetic particles modified with oleic acid.

[0065] 2) A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com