Preparation method of 1-bromonaphthalene

A technology for bromonaphthalene and industrial naphthalene is applied in the preparation field of synthesizing 1-bromonaphthalene, which can solve the problems of pollution and low utilization rate of bromine, and achieve the effects of less environmental pollution, convenient preparation process and low equipment requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

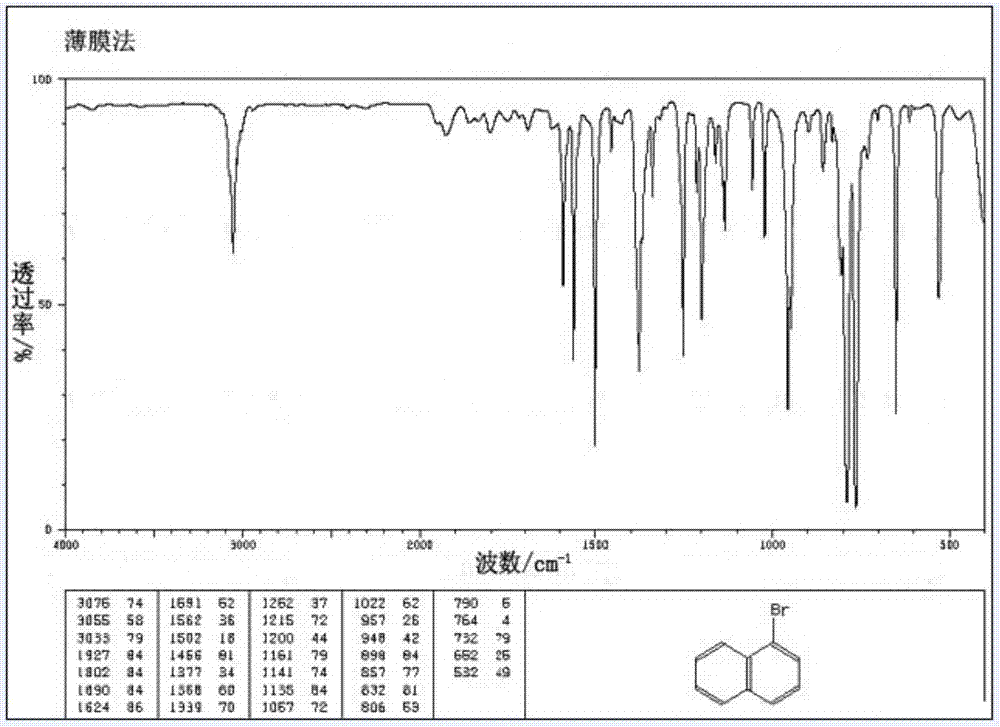

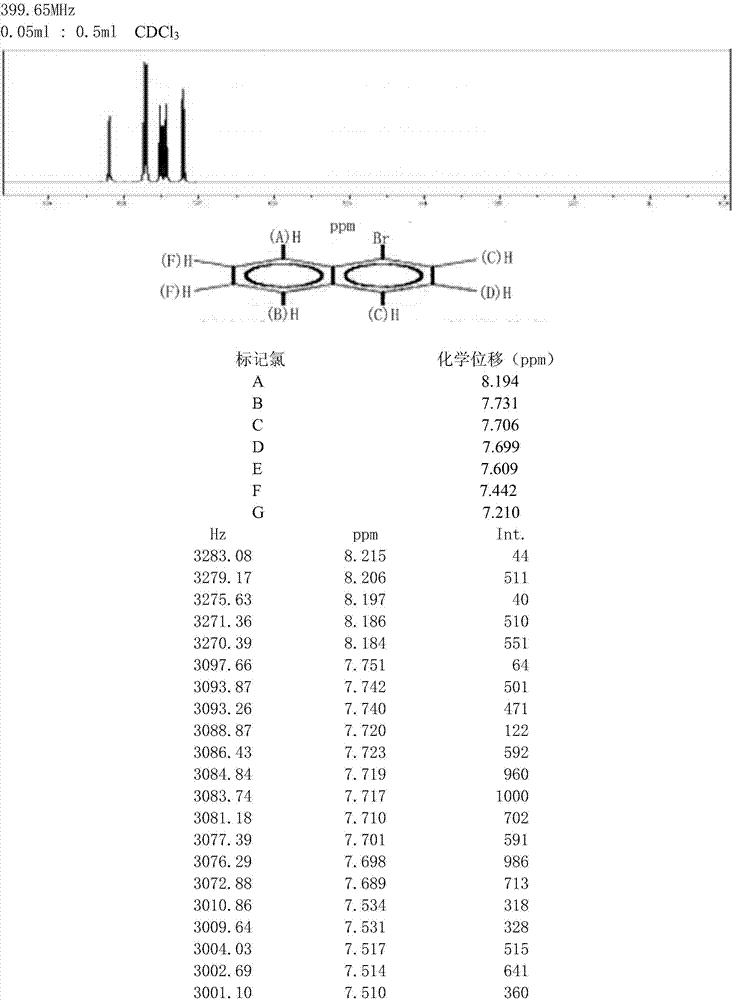

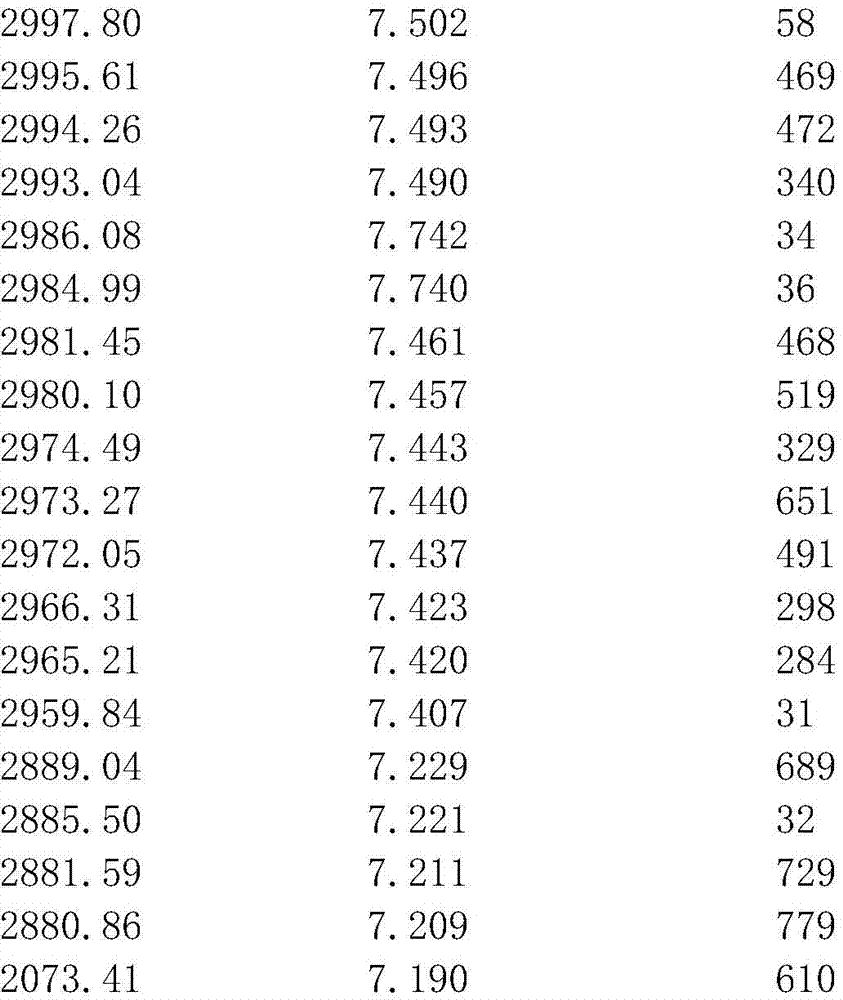

Image

Examples

Embodiment Construction

[0015] 128g of industrial naphthalene, 300ml of dichloroethane, and 167g of an aqueous solution of hydrobromic acid with a solute mass fraction of 48% were added to a 1000ml four-necked flask with a stirrer, a condenser and a thermometer, and 200ml of deionized water was added. Add 110g of 30% (solute mass fraction) hydrogen peroxide dropwise at 30-40°C, complete the dropwise addition for half an hour, and keep the reaction at 40-45°C after the drop is completed. During the reaction, follow the reaction with gas chromatography, and the reaction is complete in half an hour, and then separate it out. After dichloroethane was distilled from the water layer and the oil layer at atmospheric pressure, 192 g of 1-bromonaphthalene was obtained by distillation under reduced pressure, with a content of 98.5% (mass percentage) and a yield of 92% (calculated by the conversion rate of naphthalene).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com