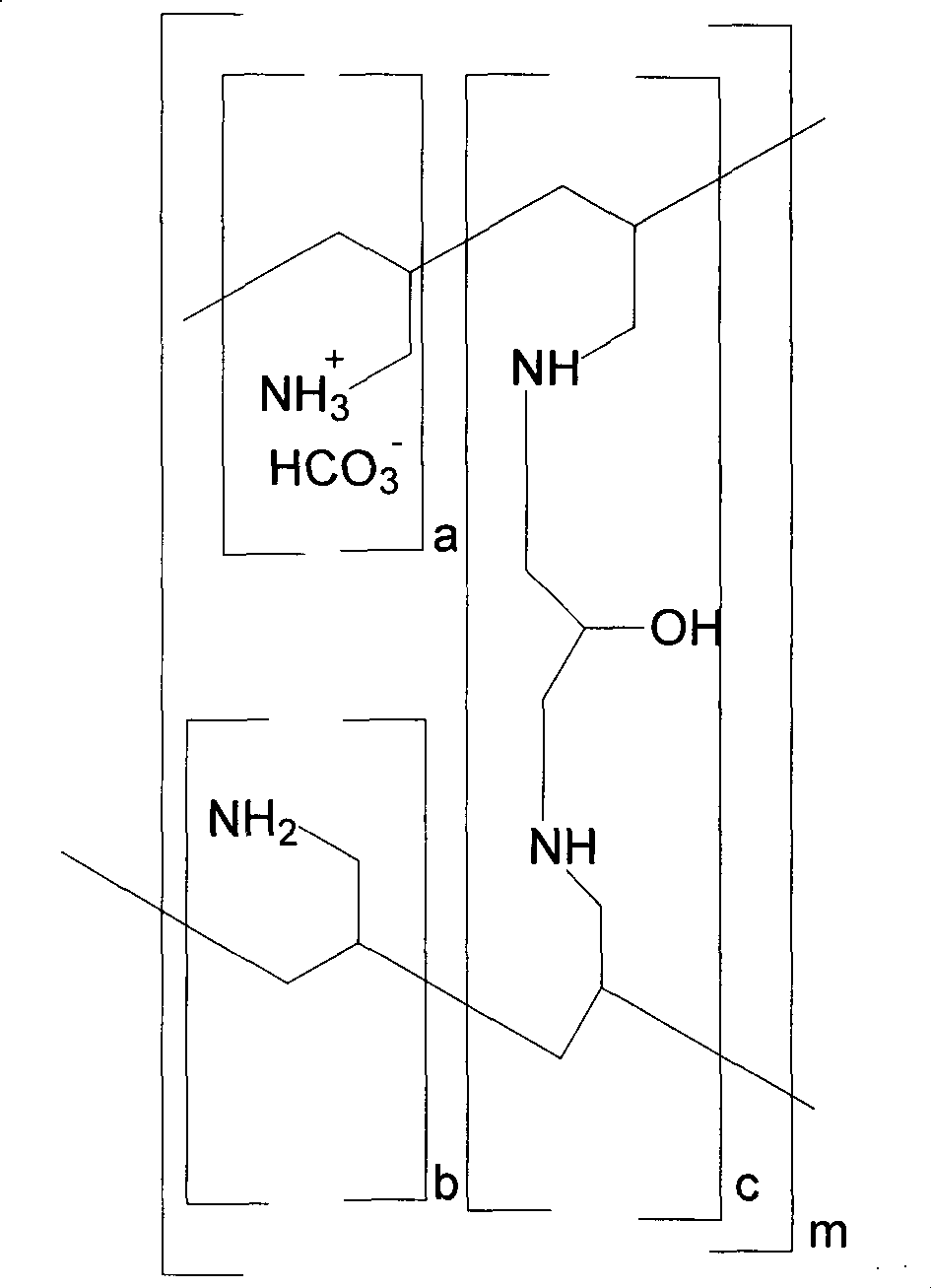

Preparation method of sevelamer carbonate

A technology of sevelamer carbonate and allylamine hydrochloride, which is applied in the field of preparation of sevelamer carbonate to achieve good formability and rapid disintegration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

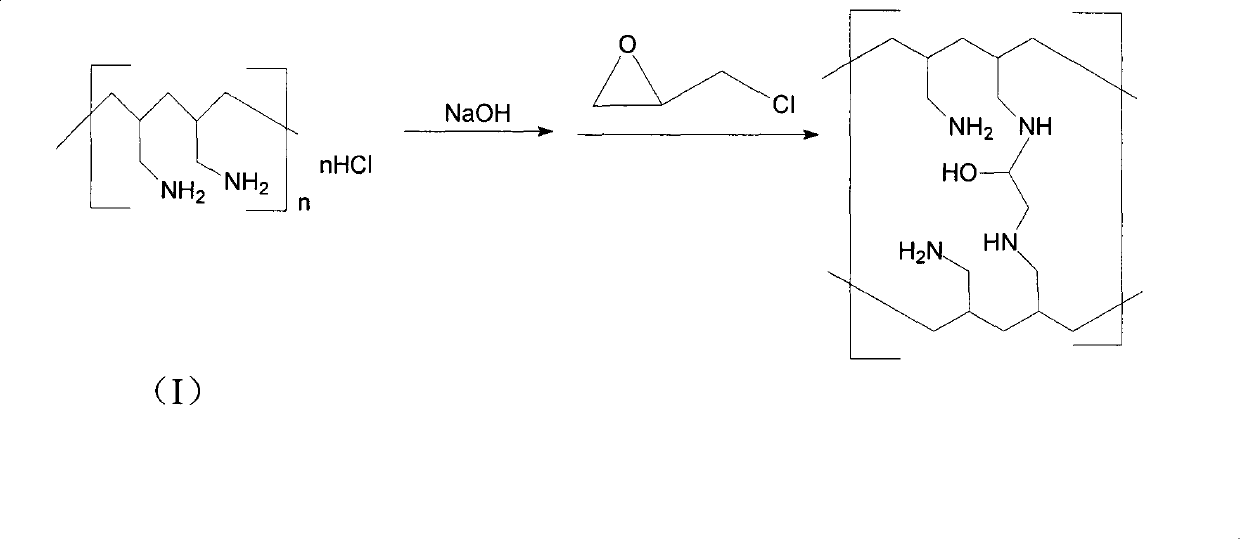

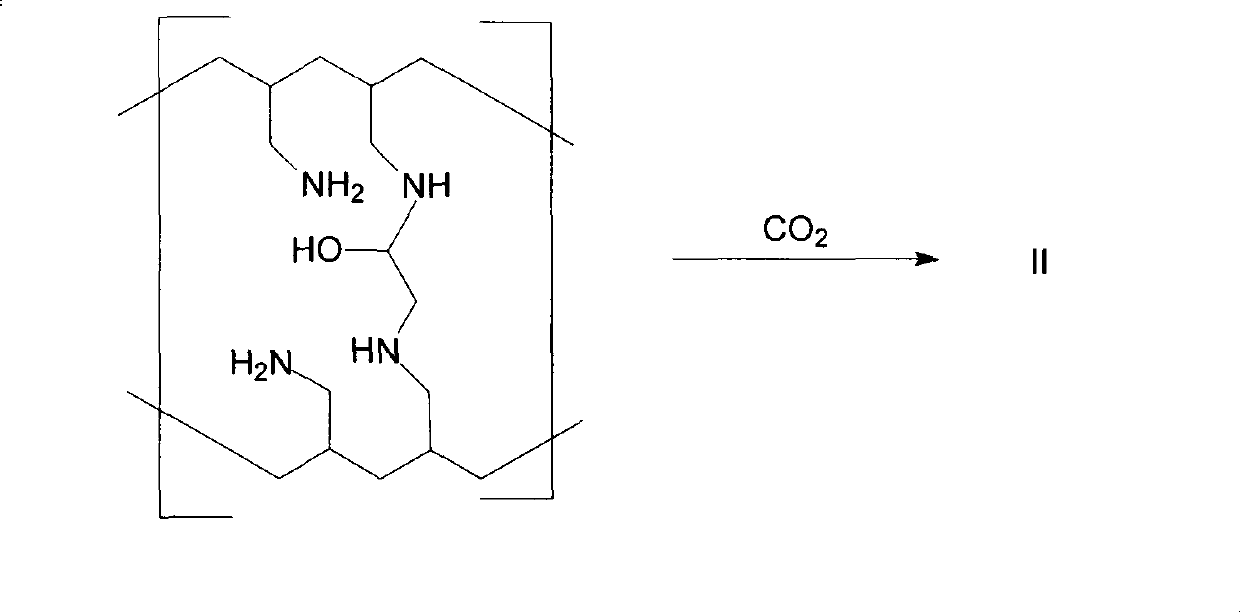

Method used

Image

Examples

Embodiment 1

[0025] Dissolve 1 kg of polyallylamine hydrochloride with an average molecular weight of 12,000 in 4 L of water, add 284 grams of sodium hydroxide, then cool to room temperature, add 59 grams of epichlorohydrin, stir until viscous, and place at room temperature for 18 hours. Crush the reactant, suspend and stir the solid in 10L, 15L, and 20L water for 1 hour and filter, add 40-50% sodium hydroxide solution, adjust the pH to 13, then filter, suspend and stir in 20L water and add dry ice until the pH =9.0-9.9, filter, dry at 60°C until constant weight, obtain off-white solid, grind and sieve to obtain Sevelamer Carbonate (carbonate content 17.5%, phosphate binding capacity 5.7, cross-linking degree 16.1 %), using this sample to prepare tablets (refer to CN101043878A). The hardness of the obtained tablet is greater than 10kg, the surface is smooth, easy to coat, and the disintegration time is 68 seconds. ( The tablet hardness of batch D0054B01 is greater than 10kg, and the dis...

example 1

[0027] With reference to the method of Example 1, the use of polymerized allylamine hydrochloride with an average molecular weight of 7000 to prepare sevelamer carbonate (carbonate content 16.8%, phosphate binding capacity 6.4, degree of cross-linking 15.6%), this sample was carried out The preparation of tablet (simultaneously the description of embodiment 1), the tablet hardness obtained is greater than 10kg smooth surface, is easy to coat, and disintegration time is extended to 22 minutes.

Embodiment 3

[0029] With reference to the method of Example 1, the use of polymerized allylamine hydrochloride with an average molecular weight of 22000 prepares sevelamer carbonate (carbonate content 18.2%, phosphate binding capacity at 5.6, cross-linking degree 15.1%), the sample Carry out the preparation of tablet (simultaneously the description of embodiment 1), the tablet hardness obtained is less than 2kg, and surface is rough, is friable in coating process, and disintegration time is: 58 seconds.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com