Efficient phosphorus-nitrogen type fire retardant and preparation method thereof

A high-efficiency phosphorus-nitrogen system and flame retardant technology, applied in the field of flame retardant materials, can solve the problems of low flame retardant efficiency of halogen-free flame retardants, achieve high char formation rate, improve flame retardant performance, and simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

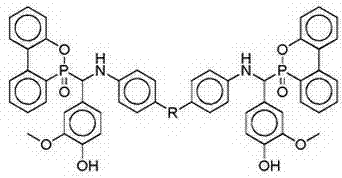

[0033] The synthesis steps of flame retardant DP-DDM are as follows:

[0034] Add 9.91 g of DDM, 15.22 g of 4-hydroxy-3-methoxybenzaldehyde and 200 mL of absolute ethanol into a three-necked flask with a stirring device. Under stirring, the reaction temperature is 40 ° C for 2 h; the reaction After the end, add 21.62 g DOPO into the three-necked flask (there is a dispersion system containing intermediate products in the three-necked flask), under the action of stirring, the reaction temperature is 60 ° C for 10 h, after the reaction, the reaction mixture is suction filtered , washing, and drying in a vacuum oven at 60°C for 8 h to obtain the required flame retardant DP-DDM with a yield of 89.2%.

[0035] After infrared spectroscopy, NMR, and mass spectrometry tests, the test and analysis results are as follows:

[0036] 1 H NMR (400 MHz, DMSO-d6) δ 8.90 (d, J = 11.4 Hz, 2H), 8.16 (dd, J = 16.3, 9.5 Hz, 4H), 8.01 – 7.94 (m, 1H), 7.79 – 7.63 (m, 3H), 7.52 (t, J = 6.7 Hz,...

Embodiment 2

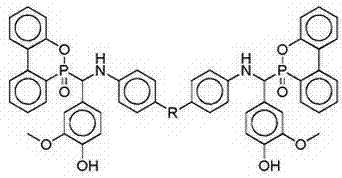

[0041] The synthetic steps of flame retardant DP-DDE are as follows:

[0042] Add 10.01g DDE, 15.22g 4-hydroxyl-3-methoxybenzaldehyde, 300 mL of dehydrated alcohol and ethyl acetate mixed solvent into a three-necked flask with a stirring device, and under stirring, the reaction temperature is React at 30°C for 4 h; after the reaction, add 21.62 g DOPO into the three-necked flask, under stirring, the reaction temperature is 30°C and react for 15 h. After the reaction, the reaction mixture is suction filtered, washed, and dried in a vacuum oven Dry at 60°C for 8 h to obtain the desired flame retardant DP-DDE with a yield of 90.8%.

[0043] The test analysis results are as follows:

[0044] 1 H NMR (400 MHz, DMSO-d6) δ 9.02 – 8.92 (m, 2H), 8.12 (t, J = 7.3 Hz, 4H), 7.87 (dd, J = 9.8, 6.0 Hz, 1H), 7.66 (dd, J = 14.4, 4.6 Hz, 3H), 7.48 – 7.18 (m, 12H), 7.11 (d, J = 8.1 Hz, 1H), 6.99 (dd, J = 7.8, 3.1 Hz, 1H), 6.91 (d, J = 18.2 Hz, 2H), 6.76 (dt, J = 13.7, 7.8 Hz, 6H...

Embodiment 3

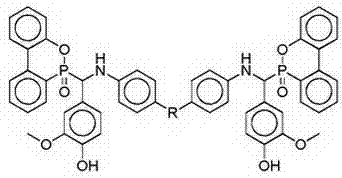

[0049] The synthesis steps of flame retardant DP-DDS are as follows:

[0050] Add 12.42g of DDS, 15.22g of 4-hydroxy-3-methoxybenzaldehyde and 400 mL of ethyl acetate into a three-necked flask with a stirring device. Under stirring, the reaction temperature is 60°C for 3 h, and the reaction After the end, 21.62 g of DOPO was added into the three-necked flask, and under stirring, the reaction temperature was 60°C for 18 h. After the reaction, the reaction mixture was suction filtered, washed, and dried in a vacuum oven at 60°C for 8 h. The desired flame retardant DP-DDS was obtained with a yield of 90.7%.

[0051] The test analysis results are as follows:

[0052] 1 H NMR (400 MHz, DMSO-d6) δ 9.02 – 8.92 (m, 2H), 8.11 (dd, J = 11.5, 4.7 Hz, 4H), 7.85 (d, J = 8.4 Hz, 1H), 7.75 – 7.59 (m, 3H), 7.47 – 7.18 (m, 12H), 7.11 (d, J = 8.1 Hz, 1H), 7.01 – 6.96 (m, 1H), 6.91 (d, J = 17.9 Hz, 2H), 6.74 (dd, J = 15.1, 10.4 Hz, 6H), 6.62 (dd, J = 8.0, 2.2 Hz, 2H), 5.43 (dd, J ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com