Compact/foamed rubber sole and its special foaming rubber

A technology of rubber soles and styrofoam, which is applied in the direction of shoe soles, applications, footwear, etc., can solve problems such as poor elasticity, shock absorption performance, easy to shock the back of the head, unfavorable soldiers and athletes, etc., to achieve good elasticity, reduce weight, increase The effect of sole comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1, the preparation of styrofoam and performance test thereof

[0024] The styrofoam in the present embodiment is made of the NR of 70.0phr, the CR of 30.0phr, the reinforcing filler of 80.0phr, the zinc oxide of 5.0phr, the accelerator TMTD of 1.5phr, the accelerator DM of 1.0phr, the accelerator DM of 1.5phr Sulfur, 2.0phr foaming agent AC, 2.0phr foaming agent H; the reinforcing filler is composed of 40.0phr high wear-resistant carbon black, 10.0phr calcium carbonate and 30.0phr rubber powder.

[0025] The specific preparation method is as follows: Use an open mill to mix rubber, first pass cooling water to ensure that the temperature of the roller is below 80°C, first masticate CR, then add NR to masticate together, and then add reinforcing filler, Zinc oxide, accelerator TMTD and accelerator DM, finally add foaming agent and sulfur, after the material powder is fully mixed into rubber, repeat rubber tapping and mixing, the whole process is 15min, and fina...

Embodiment 2

[0028] Embodiment 2, the preparation of styrofoam and performance test thereof

[0029] The component that is used to prepare styrofoam in the present embodiment is substantially the same as that in embodiment 1, and difference is: the consumption of blowing agent is adjusted to the foaming agent AC of 2.0phr; Other mixing process and embodiment Same as in 1.

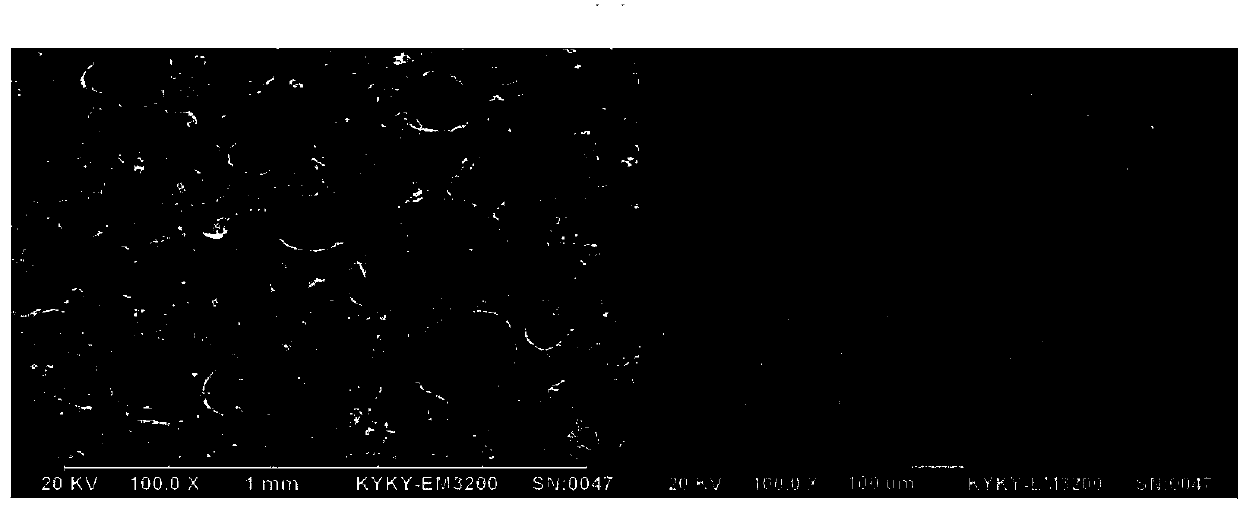

[0030] Utilize the method identical with embodiment 1 to carry out performance test and the observation of microstructure to the styrofoam prepared in this embodiment, its performance is as shown in table 1, and its scanning electron micrograph is as follows figure 2 as shown in b.

[0031] It can be seen from the data in Table 1 that with the increase of the amount of foaming agent, the foaming density of the foamed rubber decreases, which is more conducive to the weight reduction and shock absorption of finished shoes. But at the same time, the increase in the amount of foaming agent leads to a decline in the mecha...

Embodiment 3

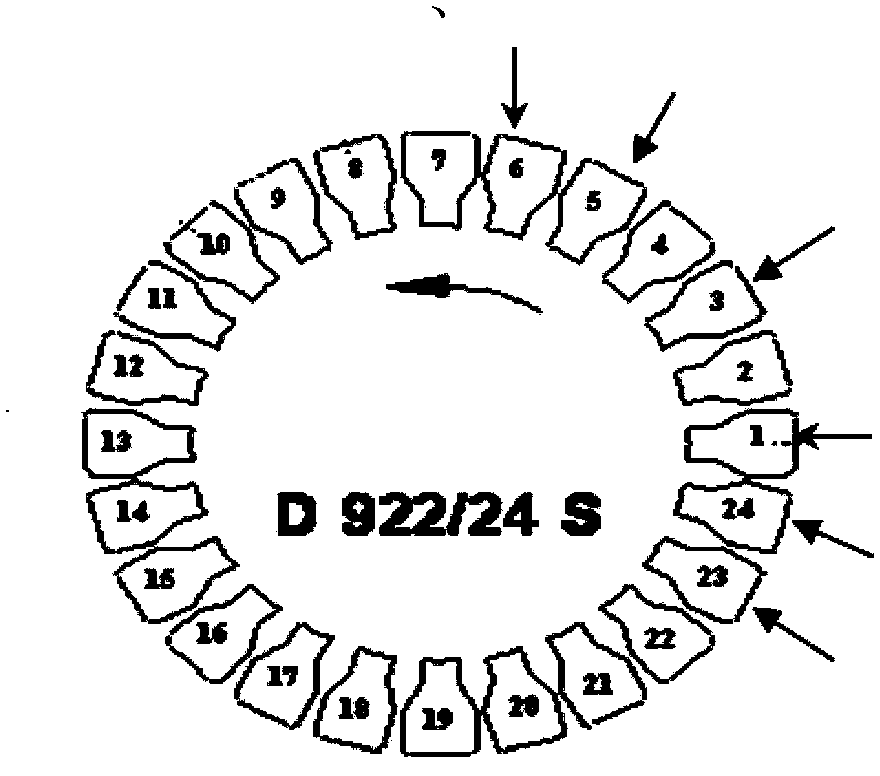

[0035] Embodiment 3, foaming / compact glue injection into shoes

[0036] First, use the internal mixer to mix the solid rubber layer according to the following formula (phr), and then produce the tablet:

[0037] CR 65.0; NR 35.0; zinc oxide 5.0; magnesium oxide 8.0; flame retardant 15.0; black ointment 10.0; antiaging agent 40102.5; accelerator M 1.0; rubber accelerator DM 1.0; sulfur 1.5; Carbon black 45.0; petroleum jelly 8.0; motor oil 3.0.

[0038] Mix the styrofoam using an open mill. First pass cooling water to ensure that the temperature of the roller is below 80°C, first masticate 20.0phr of CR, then add 80.0phr of NR to masticate together, then add 40.0phr of high wear-resistant carbon black, 10.0phr of Calcium carbonate, 30.0phr rubber powder, 8.0phr zinc oxide, 1.0phr accelerator TMTD, 1.0phr rubber accelerator DM, finally add 1.5phr foaming agent AC, 1.0phr foaming agent H and 2.0phr After the raw material powder is fully mixed into the rubber, the rubber is rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com