Modified organosilicon material-based dual-curing optical glue and application thereof

A dual-curing, silicone technology, used in non-polymer organic compound adhesives, adhesives, film/sheet adhesives, etc. and other problems, to achieve the effects of good hydrophobic properties, thin thickness and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

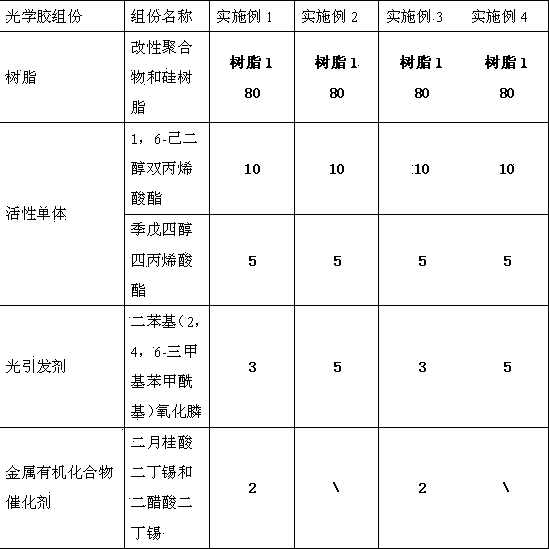

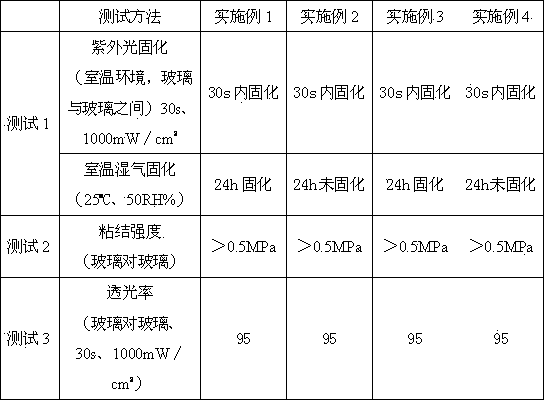

Examples

Synthetic example 1

[0027] Put allyl methacrylate and vinyl triethoxysilane into the reaction kettle according to the molar ratio of 1-10, start stirring, control the stirring speed at 20-1000 rpm, and start to heat up to 90 after adding the platinum catalyst ~100 o C, then add the mixture of hydrogen-containing silicone oil and hydrogen-containing silicone resin uniformly and continuously within 60 minutes, and maintain the reaction temperature at 90-100 o Between C, keep warm for 0.5 to 10 hours. Then, turn off stirring and cool to 50 o Below C, the discharge valve can be opened to discharge the material. The polymer and silicone resin in which allyl methacrylate and vinyltriethoxysilane are grafted or terminated together can be obtained. (hereinafter referred to as resin 1)

Synthetic example 2

[0029] First add allyl methacrylate and vinyl trimethoxysilane into the reactor according to the molar ratio of 1 to 10, start stirring, and control the stirring speed at 20 to 1000 rpm. After adding the platinum catalyst, start to heat up to 90 ~100 o C, then add the mixture of hydrogen-containing silicone oil and hydrogen-containing silicone resin evenly and continuously within 60 minutes (how much?), and maintain the reaction temperature at 90-100 o Between C, keep warm for 0.5 to 10 hours. Then, turn off stirring and cool to 50 o Below C, the discharge valve can be opened to discharge the material. The polymer and silicone resin in which allyl methacrylate and vinyltrimethoxysilane are grafted or terminated together can be obtained. (hereinafter referred to as resin 2)

Synthetic example 3

[0031] First add allyl acrylate and vinyl trimethoxysilane into the reaction kettle according to the molar ratio of 1-10, start stirring, control the stirring speed at 20-1000 rpm, and start to heat up to 90-100 rpm after adding the platinum catalyst. o C, then add the mixture of hydrogen-containing silicone oil and hydrogen-containing silicone resin evenly and continuously within 60 minutes (how much?), and maintain the reaction temperature at 90-100 o Between C, keep warm for 0.5 to 10 hours. Then, turn off stirring and cool to 50 o Below C, the discharge valve can be opened to discharge the material. A polymer and a silicone resin in which allyl acrylate and vinyl trimethoxy are grafted or terminated together can be obtained. (hereinafter referred to as resin 3)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com