Method for leaching zinc and recovering valuable metals through carrying out pressurized oxidation on zinc sulfide concentrates

A technology of zinc sulfide concentrate and pressurized oxygen leaching, applied in the direction of improving process efficiency, etc., can solve the problems of time and cost, low zinc recovery rate, unrealistic and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

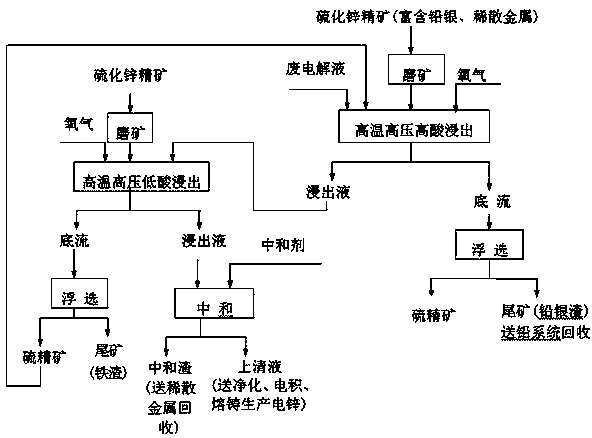

Image

Examples

Embodiment 1

[0030] The recovery of zinc, heavy metal lead, silver, scattered metal gallium, germanium, indium, etc. in zinc sulfide concentrates with different components is carried out through the following three steps:

[0031] 1) Zinc sulfide concentrate rich in lead, silver and scattered metals produced by a certain factory (element content: Zn 50.43%, Pb 1.66%, Ag 274g / t, Ga 204g / t, Ge 112g / t, In 139g / t t) After grinding, the particle size is about 25-40μm, and the solid concentration is about 65%. Pump into the reactor, feed oxygen with a concentration above 98%, and at the same time feed the waste electrolyte after purification and electrowinning to produce zinc. It is leached with high temperature, high pressure and high acid, with a temperature of 145°C, a pressure of 1100kPa, and an acidity of 60g / L. In this way, the sulfur in the zinc sulfide is oxidized to elemental sulfur, and the zinc becomes soluble zinc sulfate. After the leached pulp is cooled and pressure-reduced in the...

Embodiment 2

[0035] 1) Zinc sulfide concentrate rich in lead, silver and scattered metals produced by a certain factory (element content: Zn 50.43%, Pb 1.66%, Ag 274g / t, Ga 204g / t, Ge 112g / t, In 139g / t t) After grinding, the particle size is about 25-40μm, and the solid concentration is about 70%. Pump it into the reactor, feed oxygen with a concentration above 98%, and at the same time feed the waste electrolyte after purification and electrowinning to produce zinc, using high temperature, high pressure and high acid leaching, with a temperature of 155°C, a pressure of 1300kPa, and an acidity of 80g / L. After the leached pulp is cooled and pressure-reduced in the flash tank, it is sent to the thickener for separation to obtain the leaching solution and leaching residue (underflow). The leaching rate of zinc is 98.10%, and the leaching rate of scattered metals is 93.10% for Ga, 91.40%, and 92.20% for In. The slag is sent to flotation, the tailings are lead and silver slag, and the lead send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com