An ecological slope protection method for construction waste gabion walls

A technology for ecological slope protection and construction waste, applied in construction, botany equipment and methods, excavation, etc., can solve the problems of low efficiency, high cost, unsolved rapid greening, etc., achieve high efficiency, low labor intensity, and contribute to Soil Conservation Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] Unless otherwise specified, the improved vegetation concrete greening additive used in the embodiments of the present invention is the product provided by Patent No. ZL201110380711, and its preparation method comprises the following steps:

[0039] (a) prepare sulfur-rich bacterial powder A:

[0040] The sulfur bacteria are put into the sucrose solution for cultivation, and the powder A rich in sulfur bacteria is obtained after dehydration treatment, the addition amount of the sulfur bacteria and the sucrose solution is 1 part by weight of the sulfur bacteria, 800 to 1200 parts of the sucrose solution, The concentration of the sucrose solution is 2%; when the sulfur bacteria are cultured in the sucrose solution, the pH value of the control solution is 2~3, and the culture time is 24 hours;

[0041] (b) Preparation of mixture B:

[0042] In parts by weight, 10-18 parts of iron ore powder, 20-30 parts of calcium powder, 30-40 parts of phosphate rock powder, 10-20 parts o...

Embodiment 1

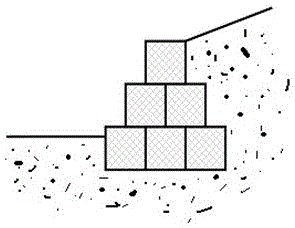

[0046] (1) The construction waste composed of broken bricks or broken concrete is crushed and screened, lime and other sundries are removed, and densely filled in the gabion box made of galvanized iron wire with a PVC protective layer. The particle size of the construction waste is larger than Gabion mesh size, but less than twice the mesh size; and on the slope or river bank that needs to be protected according to figure 1 Installed in the form shown to form a gravity gabion retaining wall.

[0047] (2) Prepare a mixture consisting of cement, clay, river sand, organic matter and improved vegetation concrete greening additives according to the following ratio, and the content of each component of the mixture per cubic meter (volume percentage):

[0048] Cement: 10%;

[0049] Clay: 70%;

[0050] River sand: 10%

[0051] Organic matter: 8%;

[0052] Improved vegetation concrete greening additive: 2%;

[0053] The above components are:

[0054] The cement is 325# ordinary Por...

Embodiment 2

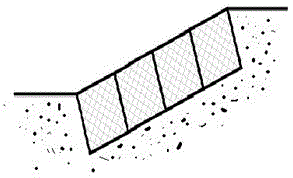

[0078] (1) The construction waste composed of broken bricks or broken concrete is crushed and screened, lime and other sundries are removed, and densely filled in the gabion box made of iron wire. The particle size of the construction waste is larger than the mesh size of the gabion. But less than twice the mesh size; and on the slope or river bank that needs to be protected according to figure 2 Installed in the form shown to form a slope-style gabion protection.

[0079] (2) Prepare a mixture consisting of cement, clay, river sand, organic matter and improved vegetation concrete greening additives according to the following ratio, and the content of each component of the mixture per cubic meter (volume percentage):

[0080] Cement: 4%;

[0081] Clay: 70%;

[0082] River sand: 15%

[0083] Organic matter: 10%;

[0084] Improved vegetation concrete greening additive: 1%.

[0085] Wherein, the above-mentioned components are respectively:

[0086] The cement is 325# ordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com