A soft and fast recovery diode and its manufacturing method

A technology of recovery diodes and manufacturing methods, which is applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as terminal reliability deterioration, softness factor reduction, device performance degradation, etc., to improve withstand voltage stability. performance, reduce reverse leakage, and improve device reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

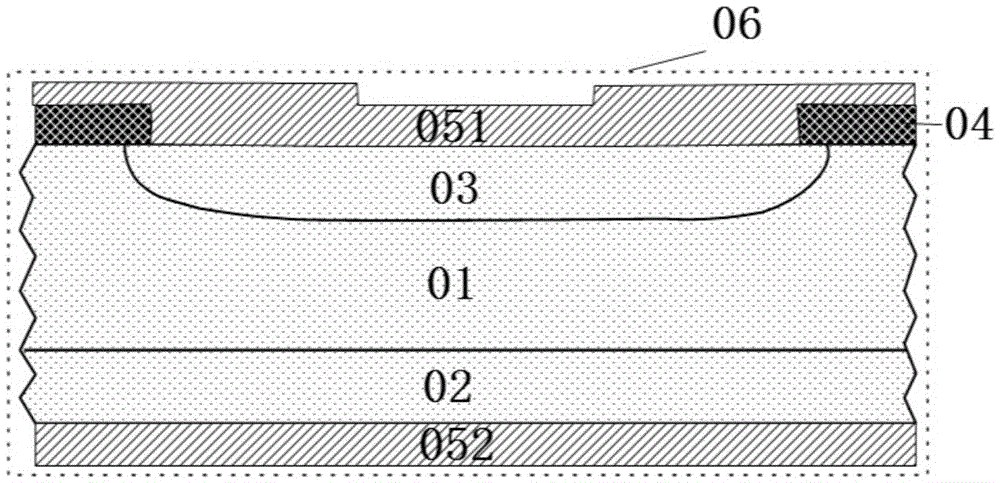

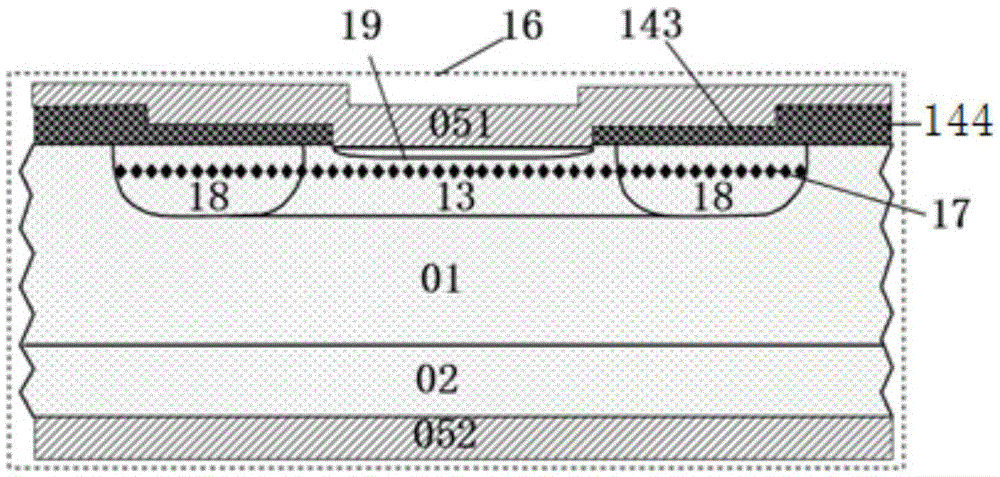

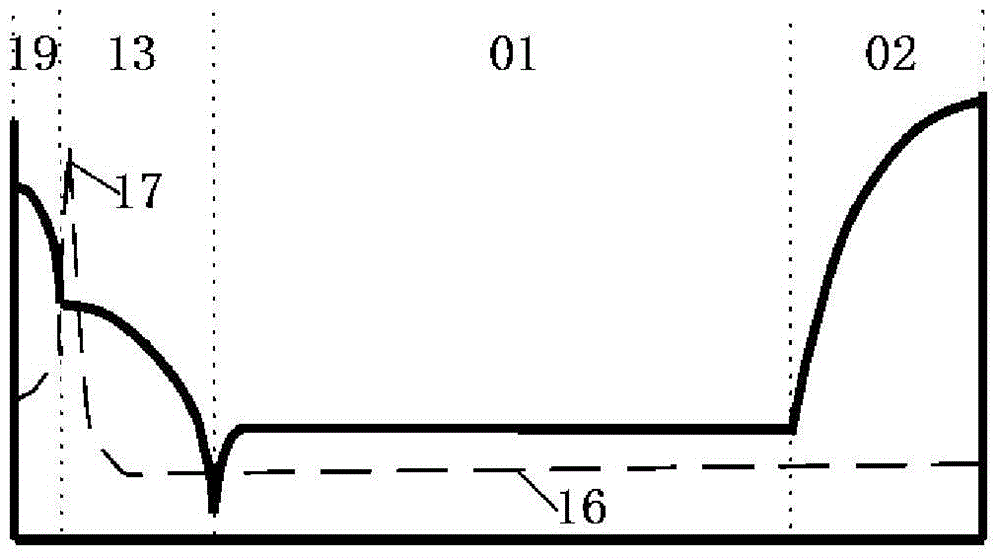

[0048] The invention provides a novel soft and fast recovery diode device structure. The vertical diode device includes a high-concentration P+ ohmic contact layer, a P-type emission region, an intrinsic region, a back N+ buffer zone, positive and negative electrodes, and a global lifetime control region and local The domain lifetime control layer; the lateral diode device includes an active area, a P-type high resistance area at the boundary of the active area, a terminal area and a scribe lane. The invention realizes the soft and fast recovery characteristics of the device by adopting the global plus local life control mode, and improves the anti-avalanche ability of the device by increasing the high-resistance area.

[0049] The present invention provides a soft and fast recovery diode structure with global and local ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com