Method for rapidly preparing polymer solution for oil displacement

A polymer solution and polymer technology, applied in the direction of mixing methods, drilling compositions, chemical instruments and methods, etc., can solve the problems of no application of supergravity technology, low preparation efficiency, difficult process, etc., and achieve energy consumption The effect of reducing, less equipment investment, and improving mass transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

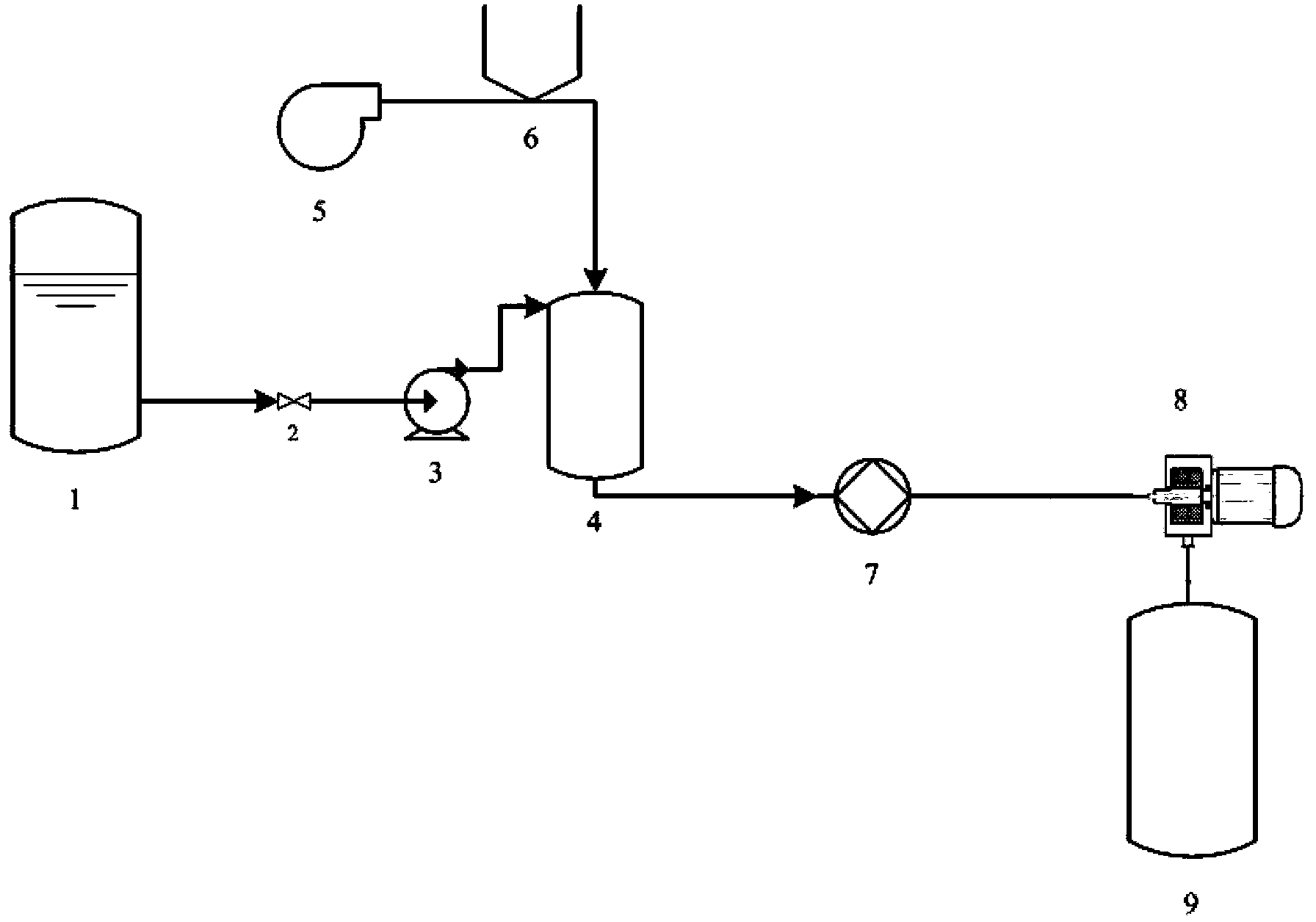

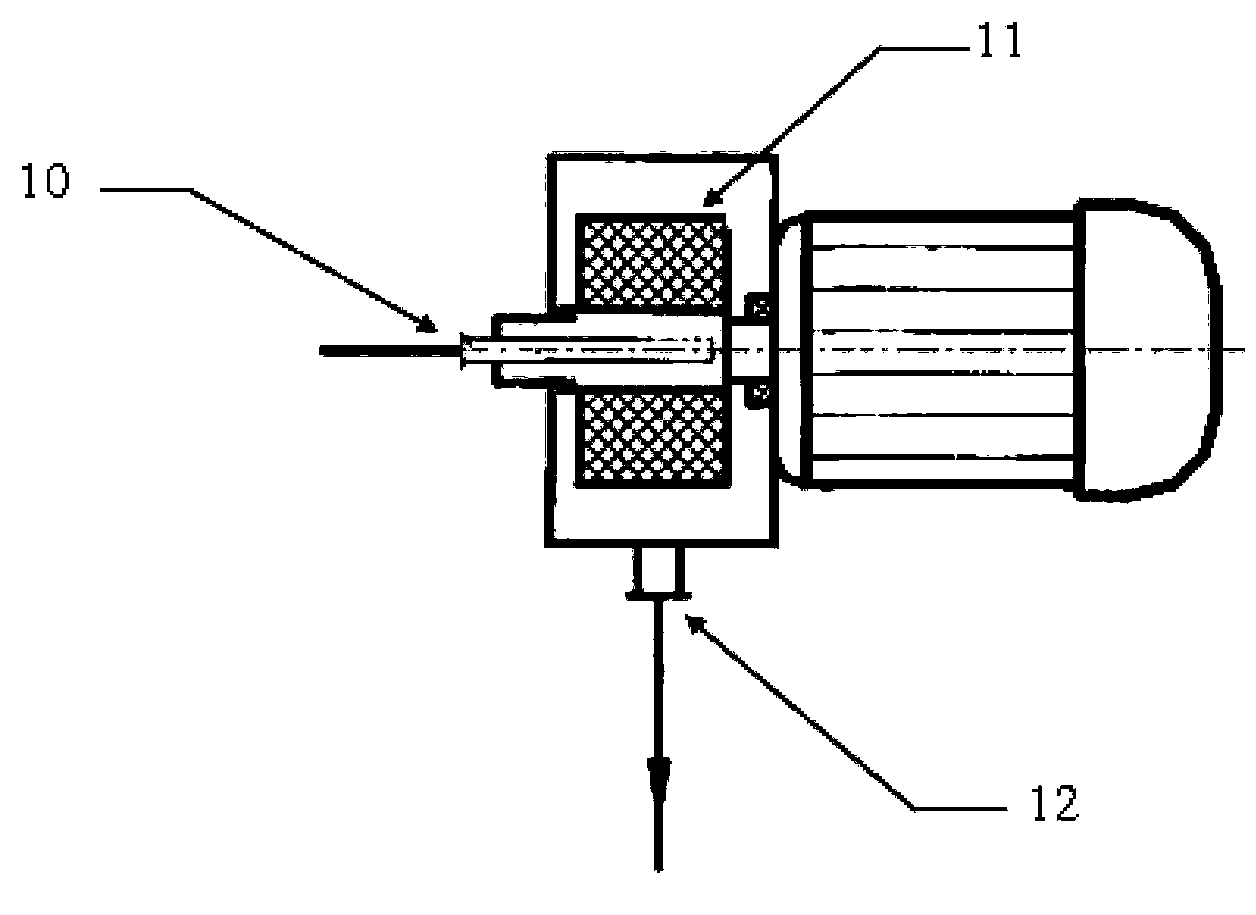

Method used

Image

Examples

Embodiment 1

[0038] A method for rapidly preparing polymer solution for oil displacement, comprising the steps of:

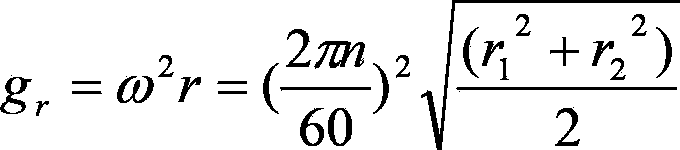

[0039] Adjust the temperature of the system to 20°C, start the supergravity rotation device, adjust the rotor speed so that the supergravity level in the rotor reaches 100 times the acceleration of gravity g; add 27.35g of polyacrylamide dry powder with a molecular weight of 25 million (moisture content 8.59%) to the polymerization The dry powder storage tank is continuously dispersed into the dispersion buffer tank by a blower; 4972.65g of pure water is added to the water tank, and it is input into the dispersion buffer tank through a water pump. The concentration of the polymer aqueous dispersion formed by water and dry powder is 5000mg / L; the dispersion liquid formed in the dispersion liquid storage tank contains a large number of dry powder micro-agglomerates that are not completely dissolved and dispersed;

[0040] Open the control valve of the liquid inlet of the supe...

Embodiment 2

[0042] A method for rapidly preparing polymer solution for oil displacement

[0043] Adjust the temperature of the system to 20°C, start the supergravity rotation device, adjust the rotor speed so that the supergravity level in the rotor reaches 150 times the acceleration of gravity g; add 27.35g of polyacrylamide dry powder with a molecular weight of 16 million (moisture content 8.59%) to the polymerization The dry powder storage tank is continuously dispersed into the dispersion buffer tank through the blower; 4972.65g of pure water is added to the water tank, and it is input into the dispersion buffer tank through the water pump. The concentration of the polymer dispersion formed by water and dry powder is 5000mg / L . The dispersion formed in the dispersion storage tank contains a large number of incompletely dissolved and dispersed dry powder micelles;

[0044] Open the control valve of the liquid inlet of the supergravity rotating device, the dispersion liquid is sprayed ...

Embodiment 3-20

[0046] Process flow and steps are the same as Examples 1 and 2, and the temperature of each embodiment, dispersion liquid concentration, polymer type, supergravity rotating device supergravity level, dispersion liquid feed volume flux and test results are shown in Table 1:

[0047] Table 1:

[0048]

[0049] It can be seen from the above Table 1 that the polymer solution for oil displacement can be rapidly prepared by the method of the present application.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com