Preparation method of biological binary composite adsorbent in glycerol triacetate refinement process

A technology of glycerol triacetate and binary compounding, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of unsatisfactory refining effects, poor selectivity of adsorbents, and high cost of use, and achieve Good natural degradation performance, improved quality, reliable and safe effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

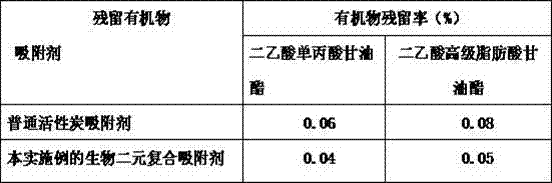

Embodiment 1

[0032] The biological binary composite adsorbent in the triacetin refining process uses β-cyclodextrin, water and granular coconut shell activated carbon as raw materials, and is prepared according to the following steps:

[0033] Weigh 4 kg of cyclodextrin and 100 kg of water according to the ratio of cyclodextrin: water = 0.04: 1; put the water into a container with stirring, heat and stir, and when the temperature reaches and maintains at 45°C, proportionally Add the cyclodextrin in four times, 1kg each time, continue to maintain the temperature, control the stirring speed at 60r / min, wait until all the cyclodextrin is added, stir and mix well, and mix evenly; heat the prepared cyclodextrin solution, The temperature was kept at 70°C to prepare cyclodextrin hydrate; according to cyclodextrin hydrate:activated carbon=1:0.05, 5 kg of granular coconut shell activated carbon and 100 kg of cyclodextrin hydrate were weighed respectively, and the granular Add coconut shell activate...

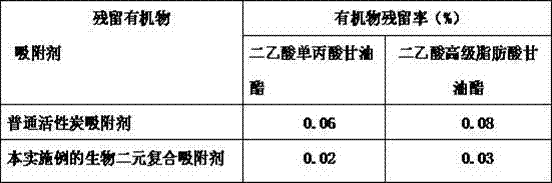

Embodiment 2

[0039] The biological binary composite adsorbent in the triacetin refining process adopts α-cyclodextrin, water and spherical fruit shell activated carbon as raw materials, and is prepared according to the following steps:

[0040] Weigh 12 kg of cyclodextrin and 100 kg of water respectively according to the ratio of cyclodextrin: water = 0.12: 1; put the water into a container with stirring, heat and stir, and when the temperature reaches and maintains at 50°C, proportionally Add the cyclodextrin in four times, 3kg each time, continue to maintain the temperature, control the stirring speed at 60r / min, wait until all the cyclodextrin is added, stir and mix well, and mix evenly; heat the prepared cyclodextrin solution, Keep the temperature at 70°C to prepare cyclodextrin hydrate; according to cyclodextrin hydrate: activated carbon = 1:0.06, weigh 7 kg of spherical fruit shell activated carbon and 117 kg of cyclodextrin hydrate respectively, and weigh the spherical fruit shell ac...

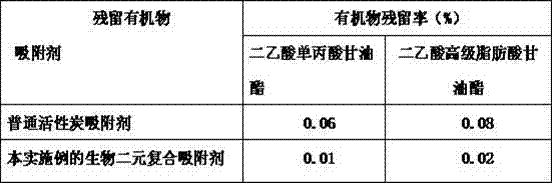

Embodiment 3

[0046] The biological binary composite adsorbent in the triacetin refining process uses γ-cyclodextrin, water and cylindrical coconut shell activated carbon as raw materials, and is prepared according to the following steps:

[0047] Weigh 28 kg of cyclodextrin and 100 kg of water respectively according to the ratio of cyclodextrin: water = 0.28: 1; put the water into a container with stirring, heat and stir, and when the temperature reaches and maintains at 45°C, proportionally Add the cyclodextrin in four times, 7kg each time, continue to maintain the temperature, control the stirring speed at 60r / min, wait until all the cyclodextrin is added, fully stir and mix, and mix evenly; heat the prepared cyclodextrin solution, Keep the temperature at 70°C to prepare cyclodextrin hydrate; according to cyclodextrin hydrate: activated carbon = 1:0.07, weigh 7 kg of cylindrical coconut shell activated carbon and 100 kg of cyclodextrin hydrate, and weigh the cylindrical coconut shell Add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com