A kind of non-precious metal isomerization catalyst and its preparation method and application

A non-precious metal and catalyst technology, applied in the field of non-precious metal catalysts and their preparation, can solve the problems of high catalyst cost, impact on economic benefits, high viscosity index, etc., and achieve low cost, high isomerization selectivity and good activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

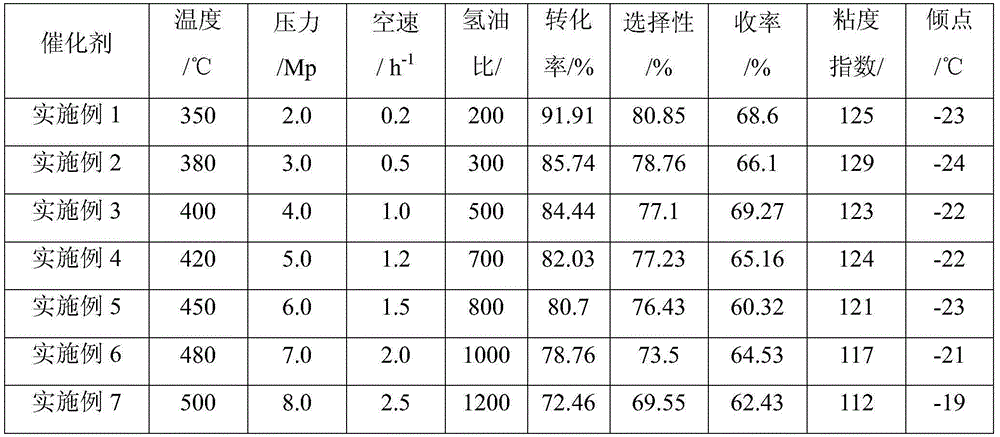

Examples

Embodiment 1

[0021] Prepare SAPO-11 molecular sieve according to the method described in patent CN101503201A: 50ml deionized water, 10ml phosphoric acid, 12g pseudoboehmite, 3.5ml tetraethyl orthosilicate, 10ml di-n-propylamine are mixed successively, stir well, and adjust the pH to 6.5, transferred to a polytetrafluoroethylene-lined reactor for crystallization at 180°C for 48 hours, cooled, washed, filtered, and dried to obtain molecular sieve powder, and roasted at 600°C for 5 hours to obtain SAPO-11 molecular sieve;

[0022] Composition of RaneyNi by final catalyst weight: V 2 o 5 =0.05:1, weigh a certain amount of NiAl 3 -Al, with a certain amount of V 2 o 5 Mix well mechanically, soak in 5.0(wt)% NaOH solution at 90°C for 6h, wash with distilled water until neutral, and dry to obtain (RaneyNi / V 2 o 5 ; Composition RaneyNi / V by final catalyst weight 2 o 5 : SAPO-11=5:1, weigh a certain amount of the above SAPO-11 molecular sieve, and RaneyNi / V 2 o 5 And safflower powder, water...

Embodiment 2

[0025] Prepare ZSM-22 molecular sieve according to the method described in patent CN103101924A: After mixing 10.4g deionized water and 0.07g aluminum sulfate evenly, add 0.22gKOH to it, stir and clarify, add 0.43g1,6-hexanediamine, under stirring Add 3g of tetraethyl orthosilicate, continue to stir until the solution evenly forms a silica-alumina gel, then place it in a reaction kettle for crystallization at 185°C for 24 hours, filter the product with suction, and dry it to obtain the original powder of ZSM-22 molecular sieve, 550°C Roasting for 6h to obtain ZSM-22 molecular sieve;

[0026] Composition RaneyNi / :Cr by final catalyst weight 2 o 3 =0.1:1, weigh a certain amount of NiAl 3 , with a certain amount of Cr 2 o 3 Mix well mechanically, soak in 50(wt)% NaOH solution at 100°C for 0.5h, wash with distilled water until neutral, and dry to obtain RaneyNi / Cr 2 o 3 ; Composition RaneyNi / Cr by final catalyst weight 2 o 3 : SAPO-11=4:1, weigh a certain amount of the abov...

Embodiment 3

[0029] Prepare SAPO-11 molecular sieve according to the method described in patent CN102381716A: weigh 10.85g pseudoboehmite, dissolve in 18.0g deionized water to make a solution, heat, stir for 0.5h; measure 9.7ml di-n-propylamine dropwise In the solution obtained in the previous step, stir for 2 hours, then weigh 10.3g of silica sol and add it to the solution, stir for 2 hours to obtain an aqueous slurry; when the aqueous slurry is heated to 80°C, add 16.45g of phosphoric acid dropwise to the aqueous In the slurry, pH=7.0, stirred for 1h, a colloidal mixture was obtained, and its molar composition was di-n-propylamine: Al 2 o 3 :P 2 o 5 : 0.6SiO2 2 : 50H 2 O, put the colloidal mixture at 190°C for 24h, cool and wash the filtrate, dry at 110°C for 12h, and then roast in a muffle furnace at 600°C for 4h to obtain SAPO-11 molecular sieve, the final composition is Al 2 o 3 :P 2 o 5 : SiO 2 =1:0.44:0.3.

[0030] Composition of RaneyNi:Fe by final catalyst weight 2 o 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com