A kind of equipment using waste fiber to make board

A technology for waste fibers and boards, which is applied in the removal of solid waste and other directions, can solve the problems of high raw material requirements, high recycling costs, increased costs, etc., and achieves the effect of saving water resources, simplifying the process and shortening the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

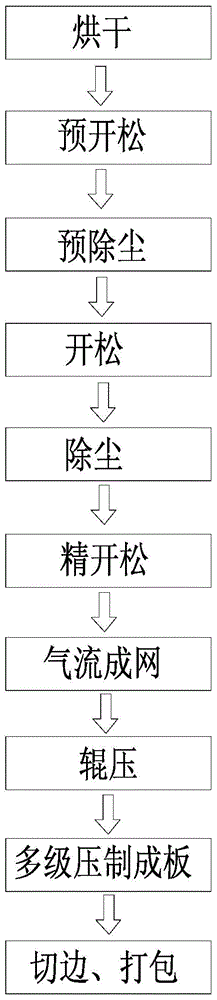

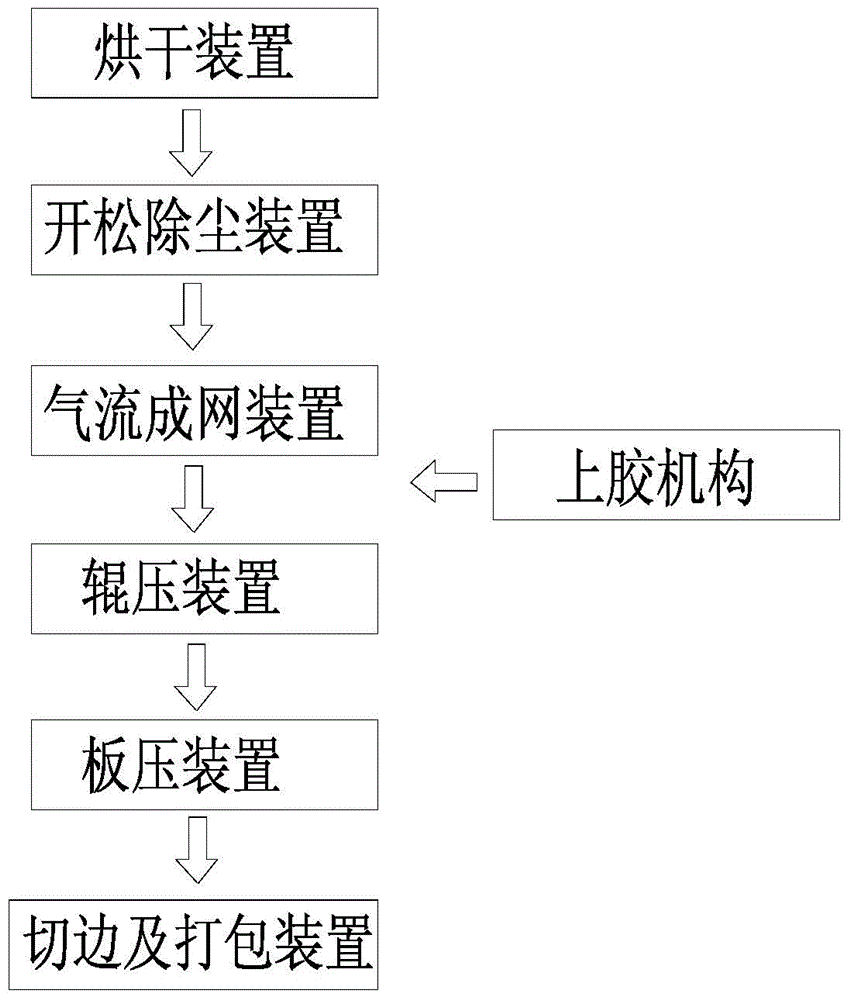

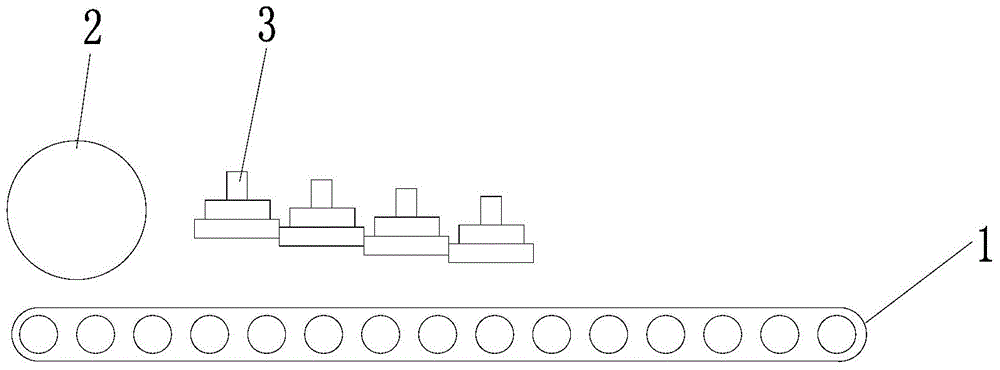

[0025] The schematic diagram of the technological process of the method for the present invention to utilize waste fiber to manufacture plate is as figure 1 As shown, waste filter bags are used as waste fiber raw materials in this embodiment, but those skilled in the art can easily understand that using waste textiles as waste fiber raw materials can also realize the present invention, as long as its main component is polyphenylene sulfide fiber , polyimide fiber, polytetrafluoroethylene fiber, polyester fiber, acrylic fiber, glass fiber, aramid fiber, flumes fiber and metas fiber and other fibers. Method of the present invention can be processed according to the following steps:

[0026] (1) Drying: Dry the waste filter bags to keep the water content of the waste fibers below 1%. If there are obvious non-fibrous substances such as steel rings...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com