A microwave catalytic oxidation equipment for treating landfill leachate

A microwave catalytic oxidation and equipment technology, which is applied in water/sewage multi-stage treatment, illuminated water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of difficult effective combination of microwave and catalytic active sites, and the service life of magnetron short, discontinuous microwave heating, etc., to achieve the effect of improving microwave utilization efficiency, prolonging service life, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

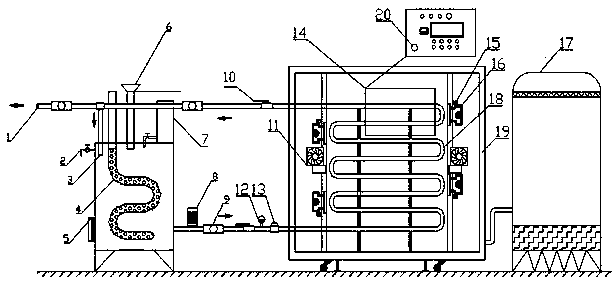

[0030] Microwave catalytic oxidation equipment see figure 1 , mainly including mixing water tank, microwave reactor, water cooling device, circulation system, automatic control system. The upper part of the mixing water tank is provided with an overflow valve 2, a water inlet 6, and a dosing tank 7, and a water level gauge 5 and an aeration pipe 4 are arranged in the mixing water tank. The microwave reactor is surrounded by a shell 19, and an outer wire 11, a magnetron 16, a transformer 15, and a coil 18 are arranged inside, and the microwave reactor is connected with a cooling system 17. The circulation system is provided with a forward connecting pipe connecting the mixing water tank and the microwave reactor, on which a circulating water pump 8, a solenoid valve 9, and a flow meter 12 are arranged, and the connecting pipe is connected with the lower end of the coil pipe 18 of the microwave reactor; the circulation system is also provided with There is a return connection p...

Embodiment 2

[0035] Utilize the microwave catalytic oxidation equipment of embodiment 1 to process landfill leachate, method is as follows:

[0036] (1) Fully mix and aerate the landfill leachate to be treated and iron carbon (30 mesh) according to 100:1 (mass ratio), and adjust the pH value to 5.0 to obtain a reaction mixture;

[0037] (2) The reaction mixture enters the coil in the microwave reactor through the water pump;

[0038] (3) Set the temperature of the microwave reactor to 80°C, the running time to 30 minutes, and start the automatic running system;

[0039] (4) Press garbage leachate into the mixed water tank during operation: 30%H 2 o 2 (Volume ratio)=100: Add H in 3 minutes and 5 times 2 o 2 solution;

[0040] (5) Adjust the pH value of the landfill leachate after microwave catalytic oxidation treatment to 9.0, and let it stand for 25 minutes.

[0041] (6) Take the supernatant to measure its COD Cr . COD Cr From 6720mg / L before treatment to 429mg / L after treatment, ...

Embodiment 3

[0043] Utilize the microwave catalytic oxidation equipment of embodiment 1 to process landfill leachate, method is as follows:

[0044] (1) Fully mix and aerate the landfill leachate to be treated and iron carbon (40 mesh) at 200:1 (mass ratio), and adjust the pH value to 4.0 to obtain a reaction mixture;

[0045] (2) The reaction mixture enters the coil in the microwave reactor through the water pump;

[0046] (3) Set the temperature of the microwave reactor to 70°C, the running time to 15 minutes, and start the automatic running system;

[0047] (4) Press garbage leachate into the mixed water tank during operation: 30%H 2 o 2 (Volume ratio)=100: Add H in 4 times in 1 minute 2 o 2 solution;

[0048] (5) Adjust the pH value of the landfill leachate after microwave catalytic oxidation treatment to 8.0, and let it stand for 15 minutes.

[0049] (6) Take the supernatant to measure its COD Cr . COD Cr From 19260mg / L to 958mg / L, the removal rate was 95.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com