High-performance polycarboxylate superplasticizer for pipe piles

A high-performance, polycarboxylic acid technology, applied in the field of cement superplasticizers, can solve problems such as bottom removal, failure to guarantee slump retention, neglect of slump retention performance, concrete workability, etc., to achieve Moderate water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

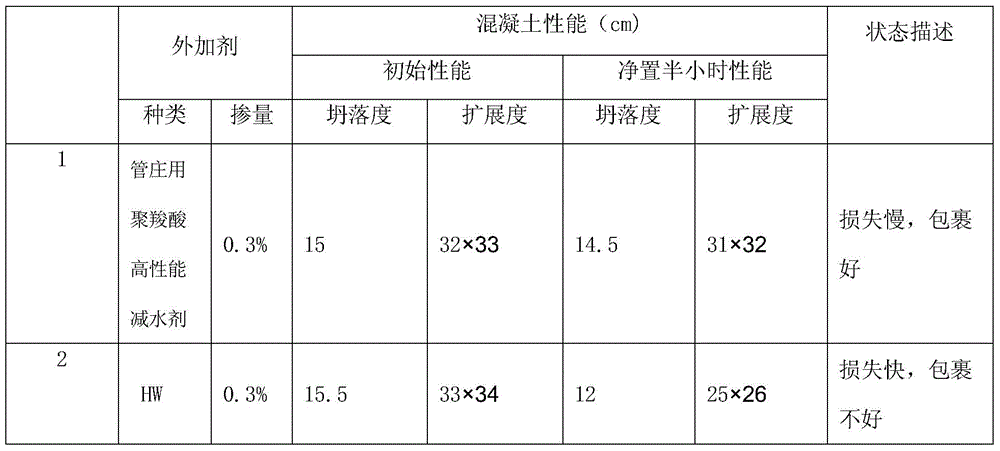

Image

Examples

Embodiment 1

[0013] 70 parts of isopentenol polyoxyethylene ether (1000), 15 parts of 2-phenylacrylic acid, 3 parts of hydrogen peroxide, 1 part of mercaptopropionic acid, and 2 parts of ascorbic acid; mix the above raw materials and react in the redox reaction system for 2 hours, The temperature is controlled at 55-65°C. After the reaction is completed, fractional distillation is carried out to remove impurities to obtain the product.

Embodiment 2

[0015] 85 parts of isopentenol polyoxyethylene ether (1500), 10 parts of 2-phenylacrylic acid, 1 part of hydrogen peroxide, 1 part of mercaptopropionic acid, and 1 part of ascorbic acid; mix the above raw materials and react in the redox reaction system for 2 hours, The temperature is controlled at 55-65°C. After the reaction is completed, fractional distillation is carried out to remove impurities to obtain the product.

Embodiment 3

[0017] 78 parts of isopentenol polyoxyethylene ether (1200), 12 parts of 2-phenylacrylic acid, 5 parts of hydrogen peroxide, 1 part of mercaptopropionic acid, and 0.5 parts of ascorbic acid; mix the above raw materials and react in the redox reaction system for 2 hours, The temperature is controlled at 55-65°C. After the reaction is completed, fractional distillation is carried out to remove impurities to obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com