Swash plate based on bismaleimide

A technology of bismaleimide and swash plate, which is applied in the field of swash plate of automobile air-conditioning compressors, can solve the problems of increasing social energy consumption, harmful social environment, and increasing the difficulty of preparation, and achieves easy control of spraying thickness, reasonable composition, The preparation process is simple and controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of swash plate based on bismaleimide, preparation comprises the following steps:

[0040] (1) Preparation of copolymer, at 150°C, add 550g of bismaleimide monomer and 450g of allyl bisphenol A monomer into a beaker, react for 30 minutes, pour the liquid into a tray, and let it cool naturally The obtained solid is bismaleimide / diallyl bisphenol A copolymer;

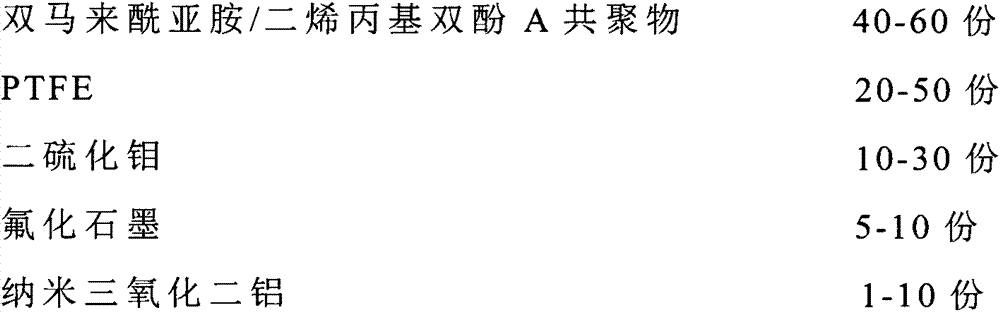

[0041] (2) Preparation of wear-resistant coating: at 50° C., bismaleimide / diallyl bisphenol A copolymer is dissolved in acetone to obtain a mass concentration of 30% copolymer acetone solution; then PTFE, Molybdenum disulfide, graphite fluoride and the reinforcing material nano-alumina are mixed evenly to obtain a solid lubricant; finally, the copolymer acetone solution is mixed evenly with the solid lubricant to obtain a wear-resistant coating solution; the mass ratio of each component for:

[0042]

[0043] (3) Spraying: first preheat the substrate 45# steel at 150°C; then spray the wear-resistant coat...

Embodiment 2

[0046] A kind of swash plate based on bismaleimide, preparation comprises the following steps:

[0047](1) Preparation of copolymer, at 150°C, add 580g of bismaleimide monomer and 420g of allyl bisphenol A monomer into a beaker, react for 30 minutes, pour the liquid into a tray, and let it cool naturally The obtained solid is bismaleimide / diallyl bisphenol A copolymer;

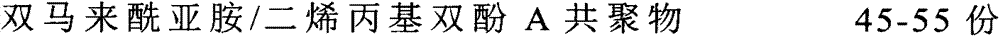

[0048] (2) Preparation of wear-resistant coating: at 50° C., bismaleimide / diallyl bisphenol A copolymer is dissolved in acetone to obtain a mass concentration of 35% copolymer acetone solution; then PTFE, Molybdenum disulfide, graphite fluoride and the reinforcing material nano-alumina are uniformly mixed to obtain a solid lubricant; finally, the copolymer acetone solution and the solid lubricant are uniformly mixed to obtain a wear-resistant coating solution; the mass ratio of each component for:

[0049]

[0050]

[0051] (3) Spraying: first preheat the substrate 45# steel at 150°C; then spray the we...

Embodiment 3

[0054] A kind of swash plate based on bismaleimide, preparation comprises the following steps:

[0055] (1) Preparation of copolymer, at 150°C, add 600g of bismaleimide monomer and 400g of allyl bisphenol A monomer into a beaker, react for 30 minutes, pour the liquid into a tray, and let it cool naturally The obtained solid is bismaleimide / diallyl bisphenol A copolymer;

[0056] (2) Preparation of wear-resistant coating: at 50° C., bismaleimide / diallyl bisphenol A copolymer is dissolved in acetone to obtain a mass concentration of 33% copolymer acetone solution; then PTFE, Molybdenum disulfide, graphite fluoride and the reinforcing material nano-alumina are uniformly mixed to obtain a solid lubricant; finally, the copolymer acetone solution and the solid lubricant are uniformly mixed to obtain a wear-resistant coating solution; the mass ratio of each component for:

[0057]

[0058] (3) Spraying: first preheat the substrate 45# steel at 150°C; then spray the wear-resistan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com