Papermaking coating and preparation method thereof as well as coated paper using papermaking coating

A technology for coating paper and coatings, applied in paper coatings, papermaking, textiles and papermaking, etc., can solve the problems affecting production operation, poor dispersion, poor uniformity of papermaking coatings, etc., achieve effective dispersion regulation, provide antibacterial functions, The effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of the above-mentioned papermaking coating comprises the following steps: firstly add 20-40 parts by absolute dry mass of acrylic latex to the container, and then slowly add 50-80 Parts by mass of nano-titanium dioxide powder, while adding 2.4-6.4 parts by mass of ethanol dropwise (preferably in the form of an aqueous ethanol solution); stir evenly (about 40 minutes) and add 0.3-1.0 parts by mass of dispersant (silicon NaOH); after stirring evenly (about 10min), add 20-50 parts by mass of light calcium carbonate to the container; after stirring evenly (about 20min), selectively add NaOH solution to the container to adjust the pH value between 8 and between 9.

[0018] A coated paper comprises base paper and a coating coated on the surface of the base paper. The coating is formed by coating the surface of the base paper with the above-mentioned papermaking coating and drying. The coating amount of the papermaking coating is 10-20g / m 2 , and form ...

Embodiment 1

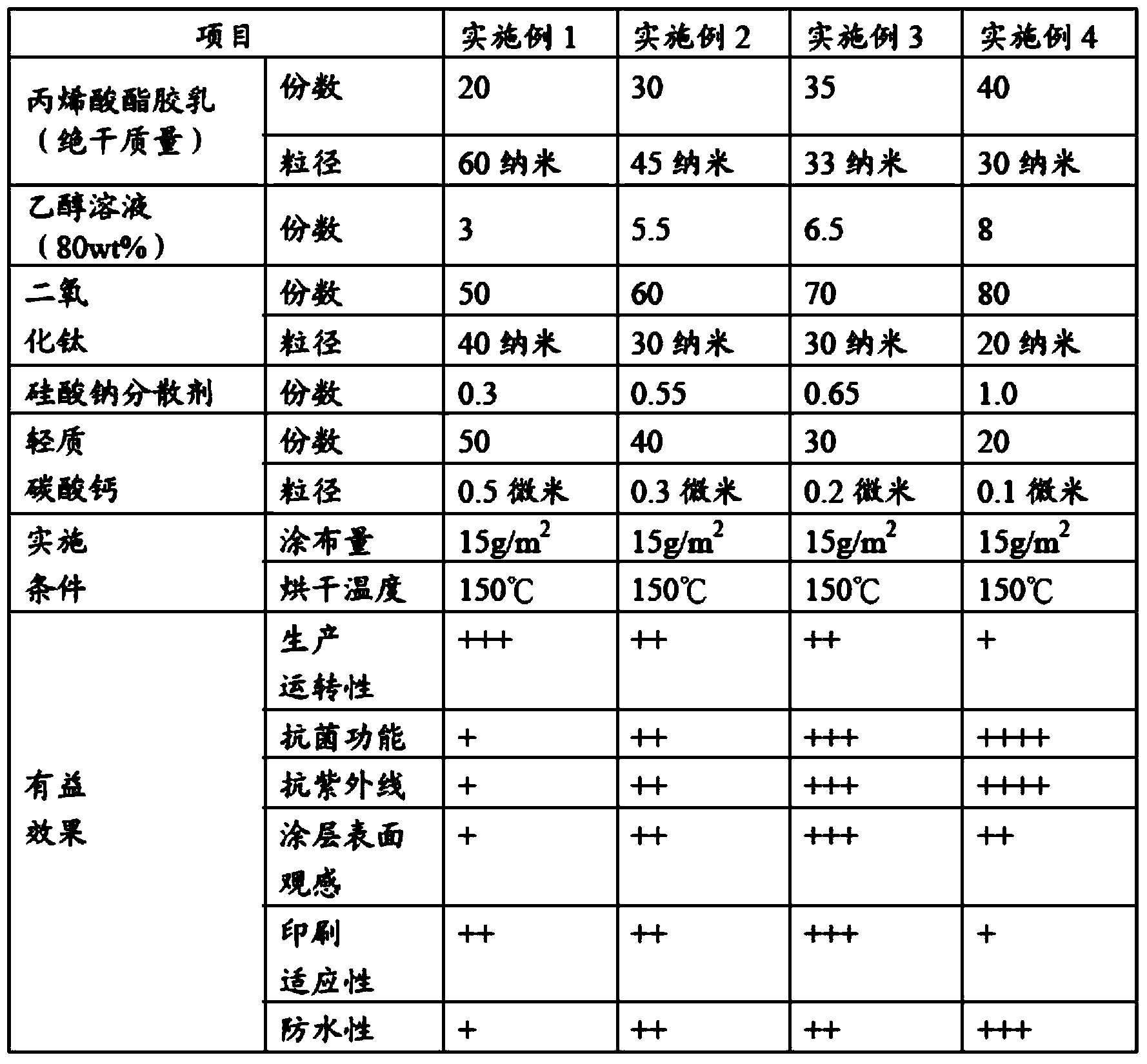

[0022] Add acrylic latex (solid content 35%), nano-titanium dioxide dry powder, ethanol solution (mass percentage concentration 80%), sodium silicate dispersant, needle-shaped light calcium carbonate in the container, add NaOH solution after stirring to adjust the pH value to 8.5, that is, the paper coating is prepared. Please refer to Table 1 for specific experimental parameters and conditions.

[0023] The papermaking coating prepared in Example 1 was coated on the base paper surface and dried to obtain a coating.

Embodiment 2

[0025] Refer to the method and steps of Example 1 to configure the papermaking coating and coat the base paper. Please refer to Table 1 for different experimental parameters.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com