A flange joint two-plate diversion zinc alloy vertical one-way valve

A flange joint and zinc alloy technology, which is applied in the direction of lifting valves, control valves, valve devices, etc., can solve the problems of increasing the gas phase load of the pipeline, increasing energy consumption, and operating fluctuations of the decompression device, so as to reduce the processing accuracy requirements, Avoid accidental failure, fast and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described with embodiment:

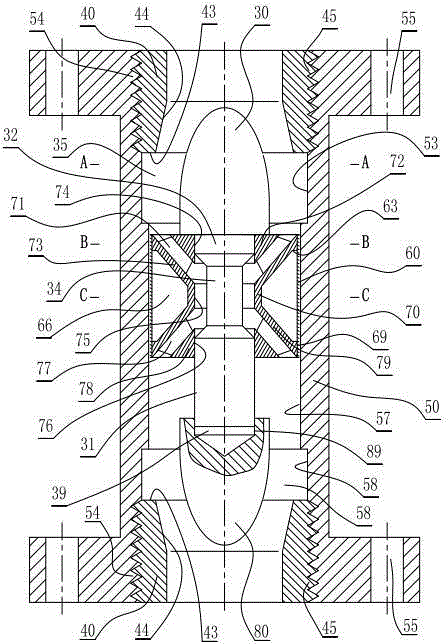

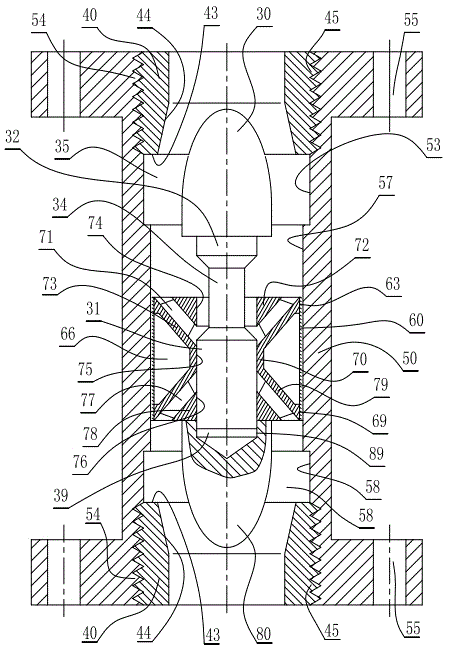

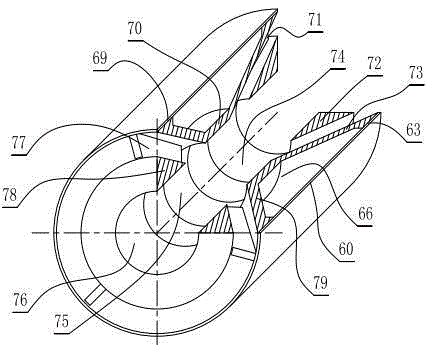

[0029] Figure l, figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 with Figure 7Among them, a flange joint two-plate flow-guiding zinc alloy vertical one-way valve, including a flange head valve body 50, an upper guiding body 30, a cavity sleeve 60, a moving valve core 70, a lower guiding body 80, and a symmetrical arrangement up and down The tapered hole gland 40, the upper and lower ends of the outer circle of the flange head valve body 50 have flat flanges 55, and the upper and lower inner circle through holes 57 of the flange head valve body 50 have upper and lower stepped holes 53 and The lower step hole 58, the upper end of the upper step hole 53 and the lower end of the lower step hole 58 respectively have fastening internal screw holes 54; the plane end of the upper guide body 30 is fixedly connected to the upper cylinder 32, and the upp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com