Electrolytic cells for studying the electrochemical behavior of electroactive oxides in molten electrolytes

A molten electrolyte and electrolytic cell technology, applied in the field of electrolytic cells, can solve problems such as difficulty in conducting stable and reliable electroactive ion electrochemical research and testing, and achieve the effects of avoiding direct short-circuit of electrons, stable and reliable performance, and preventing adverse effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

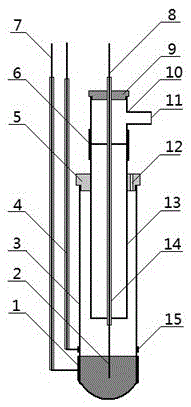

[0021] An electrolytic cell for studying the electrochemical behavior of electroactive oxides in molten electrolytes. Such as figure 1 As shown, the electrolytic cell includes ZrO 2 Tube 3, reference electrode 15, auxiliary electrode 1 and solid-state working electrode 2. ZrO 2 The closed end of tube 3 is filled with molten electrolyte, ZrO 2 The open end port of the tube 3 is equipped with an alumina plug 5; in ZrO 2 The outer surface of the closed end of the tube 3 is surrounded and sintered with an auxiliary electrode 1 and a reference electrode 15 in sequence from bottom to top, and the upper boundary of the auxiliary electrode 1 is connected with ZrO 2 The liquid level of the molten electrolyte in the tube 3 is even, and the reference electrode 15 is close to the upper boundary of the auxiliary electrode 1; one end of the reference electrode lead 4 is fixedly connected to the reference electrode 15, and one end of the auxiliary electrode lead 7 is fixedly connected to...

Embodiment 2

[0029] An electrolytic cell for studying the electrochemical behavior of electroactive oxides in molten electrolytes. Except following technical parameter, all the other are with embodiment 1:

[0030] The dopant is Y 2 o 3 , ZrO 2 The inner diameter of the tube 3 is 10-15 mm, and the wall thickness is 1.5-2.5 mm.

[0031] The materials of the auxiliary electrode 1 and the reference electrode 15 are both platinum, the thickness of the platinum layer is 20-35 μm, and the porosity is 25-35%.

[0032] The material of the solid working electrode 2 is inert metal iridium, and the diameter of the solid working electrode 2 is 1-2 mm.

Embodiment 3

[0034] An electrolytic cell for studying the electrochemical behavior of electroactive oxides in molten electrolytes. Except following technical parameter, all the other are with embodiment 1:

[0035] The dopant is Y 2 o 3 , ZrO 2 The inner diameter of the tube 3 is 15-20mm, and the wall thickness is 2-3mm.

[0036] The auxiliary electrode 1 and the reference electrode 15 are made of platinum, the thickness of the platinum layer is 35-50 μm, and the porosity is 30-40%.

[0037] The material of the solid working electrode 2 is inert metal rhodium, and the diameter of the solid working electrode 2 is 0.2-1.2mm.

[0038] When performing high-temperature measurement in this specific embodiment, the electrolytic cell is placed in a constant temperature zone in a tubular high-temperature furnace, and air with a flow rate of 100-600 mL / min passes through the high-temperature furnace. Therefore, the outside surface of the electrolytic cell is in a flowing air environment. Ar or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com