Method for manufacturing tunable photonic crystal and tunable photonic crystal

A technology of photonic crystals and manufacturing methods, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of high price, long time consumption, and restricted application range, etc., and achieve the effects of fast response speed, convenient implementation, and various means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

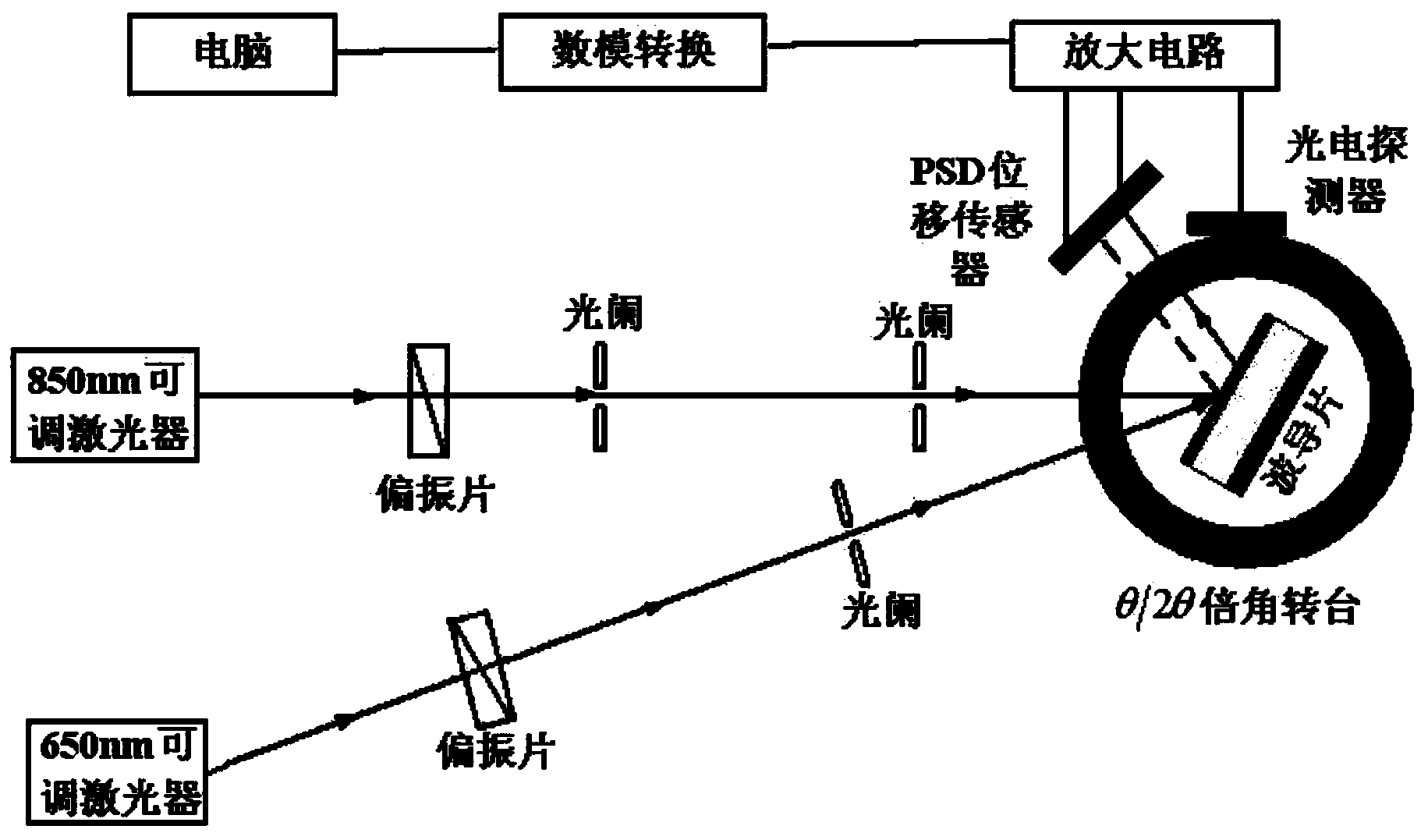

[0042] In this embodiment, photodetectors are selected to detect changes in the reflectivity of the probe light, such as image 3 As shown, under the premise that the detection light is not turned on, the θ / 2θ turntable is rotated, and the light intensity of the pump light measured by the photodetector is observed at the same time, so that the light intensity reaches the minimum value. Turn on the detection light, and use the photodetector to record the change of the reflectivity of the detection light, turn off the pump light, and the signal measured by the photodetector will change accordingly, after the measured signal is stable, turn on the pump light until the signal reappears Stable, repeat the above steps, you can detect if Figure 4 Shown is the effect of the light reflectance being modulated by the switching pump light.

[0043] Depend on Figure 4 It can be seen that the reflectance of the probe light will change with whether the pump field is applied, and the refl...

Embodiment 2

[0045] Different from Embodiment 1, this embodiment uses a PSD displacement sensor to record the change of the lateral displacement of the reflected light beam of the detection light. On the premise that the detection light is not turned on, the θ / 2θ turntable is rotated, and the light intensity of the pump light measured by the photodetector is observed at the same time, so that the light intensity reaches the minimum value. Turn on the probe light, and use the PS sensor to record the lateral displacement change of the reflected light of the probe light, turn off the pump light, and the signal measured by the photodetector will change accordingly, after the measured signal is stable, turn on the pump light until the signal Stabilize again, repeat the above steps, you can detect the effect of the lateral displacement of the reflected light with the modulation of the switching pump light, the effect is as follows Figure 5 shown.

[0046] Depend on Figure 5 It can be seen th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com