Manufacturing method of submicron photonic crystal phase array light beam splitter

A production method and technology of photonic crystals, applied in optics, instruments, optical components, etc., can solve problems such as crystal structure complexity, achieve uniform intensity distribution, and expand the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

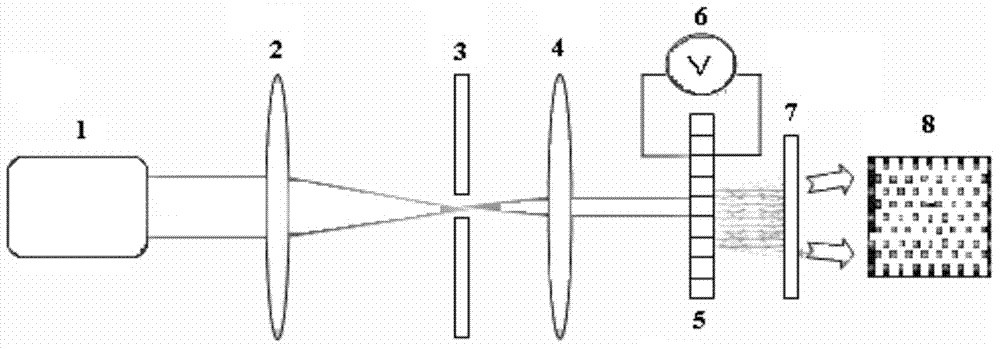

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

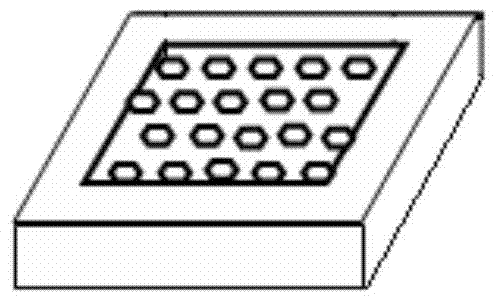

[0022] The two-dimensional submicron photonic crystal phase array optical beam splitter proposed by the present invention mainly utilizes the electro-optical effect and piezoelectric effect of photonic microstructure crystals, and applies an external electric field to modulate the change of crystal refractive index and piezoelectric thickness. , realize the phase change to form a phase array grating, and uniform diffraction beam splitting occurs when the plane light wave passes through the phase grating.

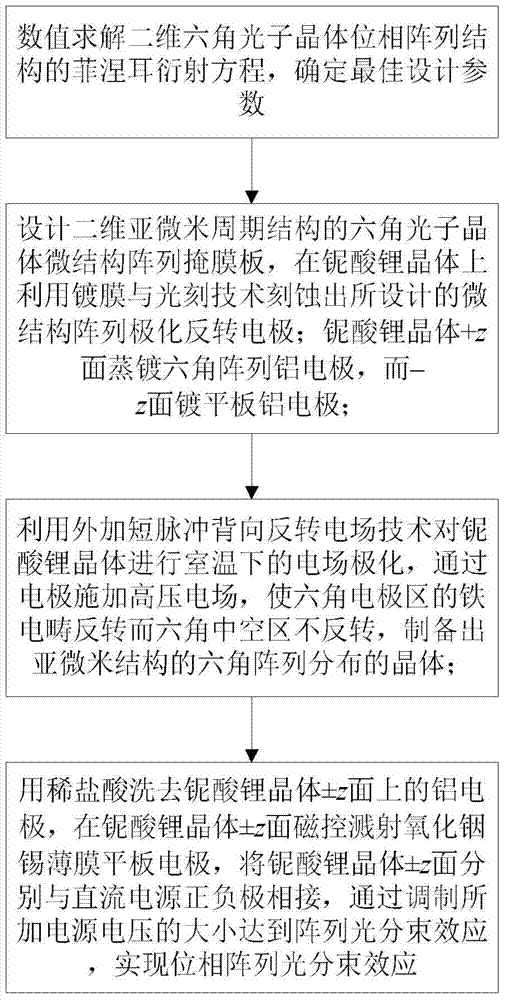

[0023] The manufacture method flow process of the optical beam splitter designed by the present invention is as follows figure 1 As shown, specifically:

[0024] 1) The present invention utilizes the Fresnel diffraction theory and the Fourier transform theory of the secondary phase factor to analyze the Tablot effect diffraction of the two-dimensional photonic micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com