Preparation method for semiconductor device with improved surge current resistance

A semiconductor, anti-surge technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve problems such as increased conduction voltage drop, increased device conduction loss, and device damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

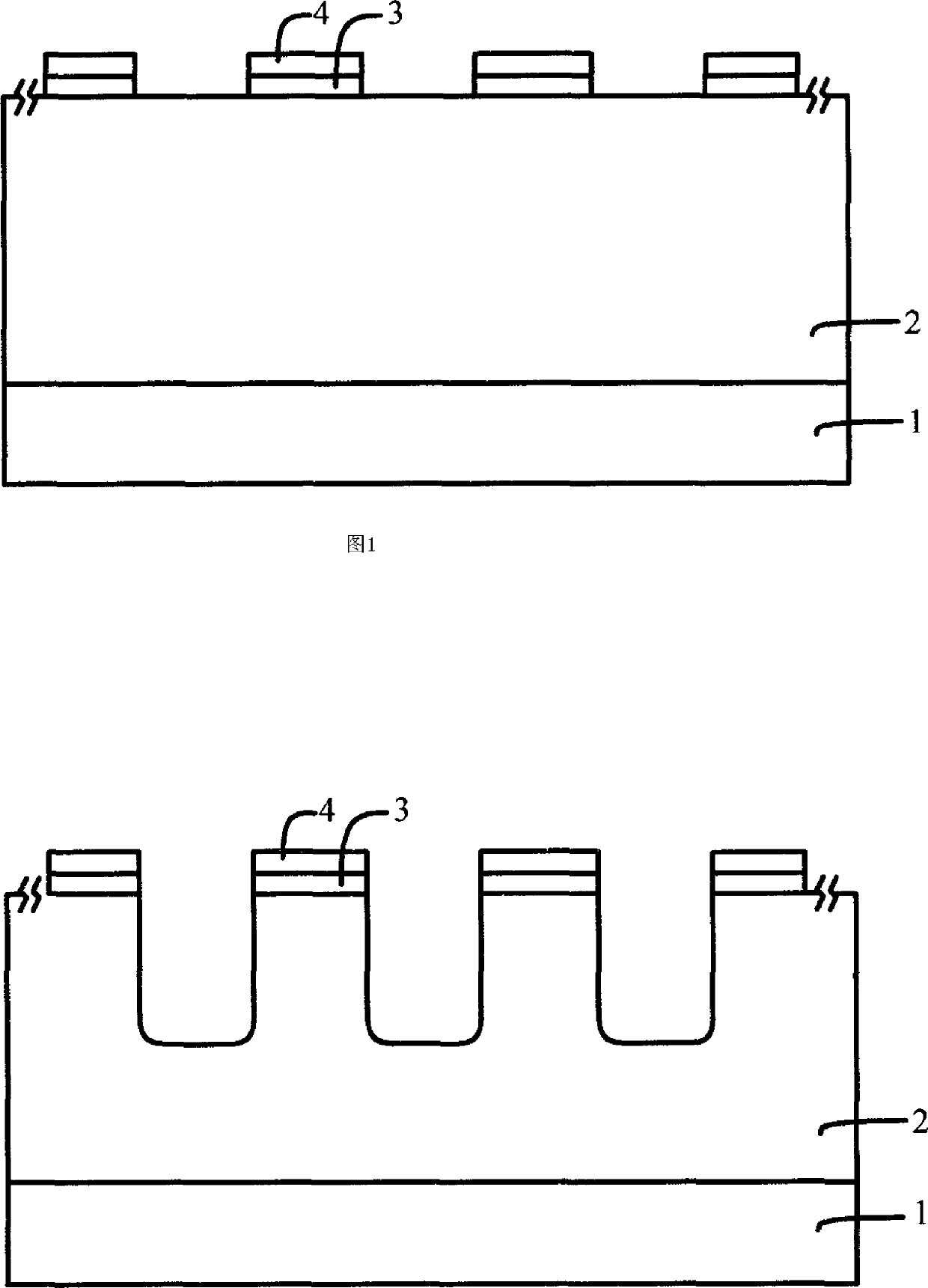

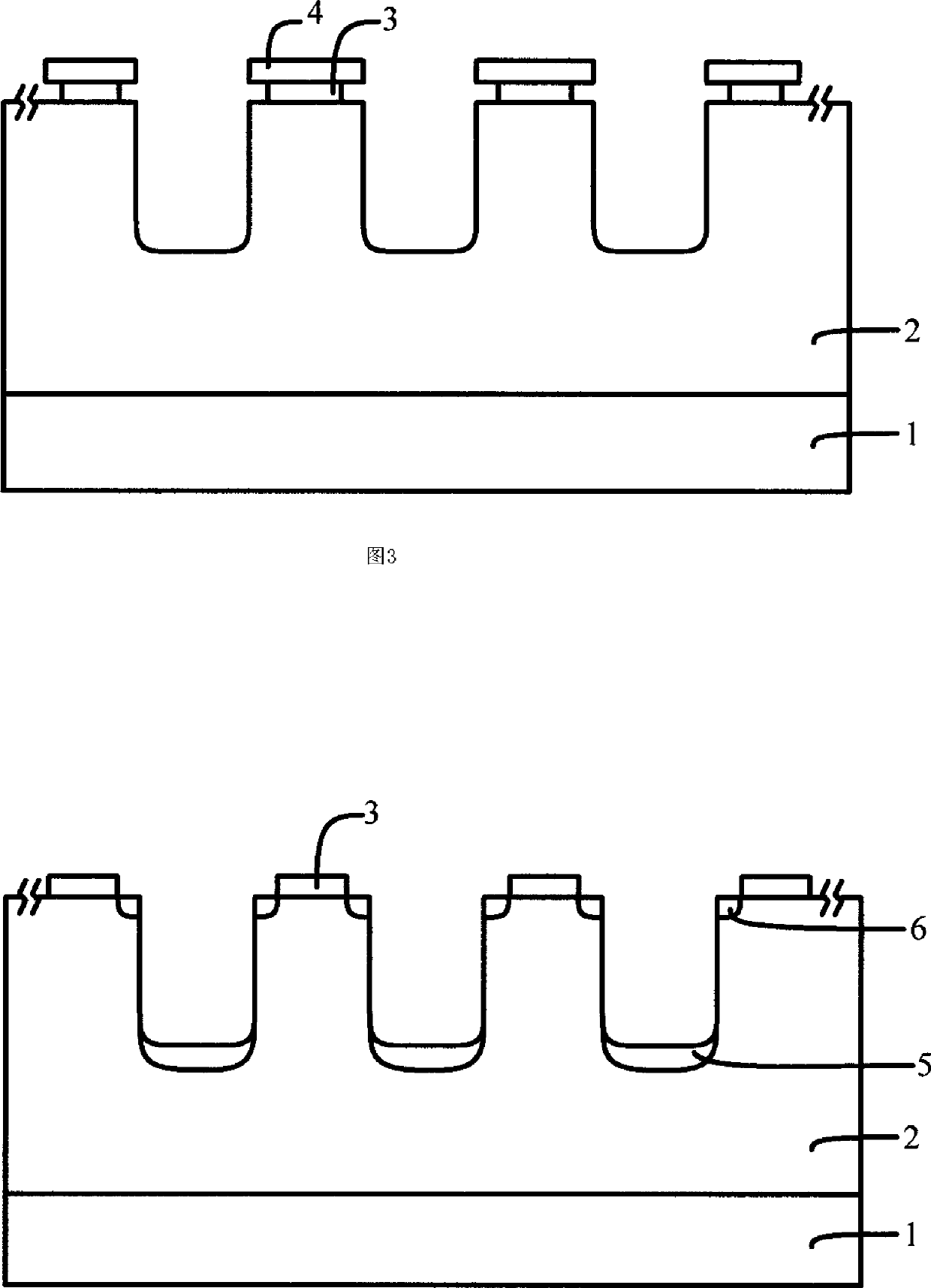

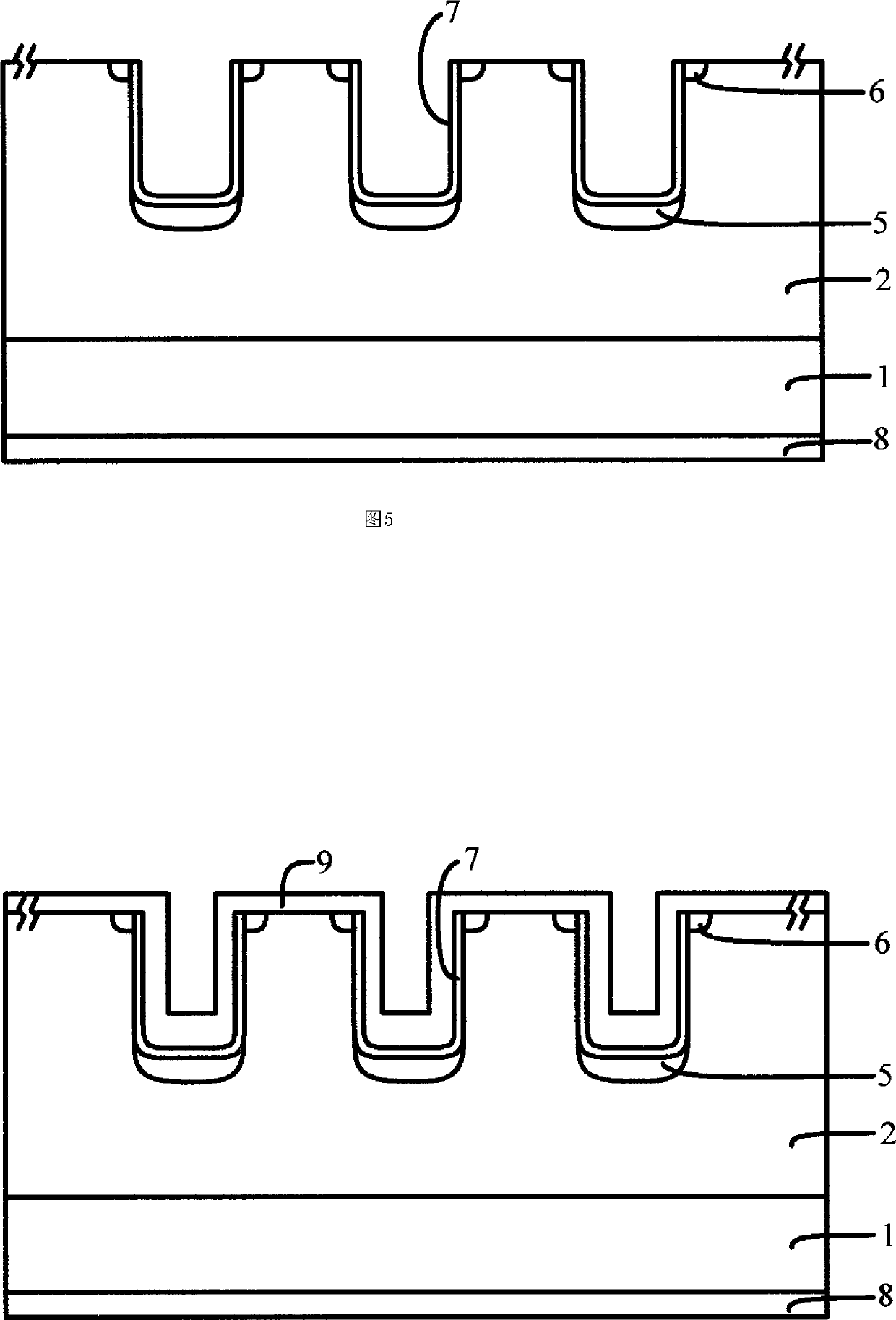

[0023] Image 6 In order to be a cross-sectional view of a semiconductor device with improved anti-surge current capability of the present invention, the following is combined Image 6 The semiconductor device of the present invention will be described in detail.

[0024] A semiconductor device with anti-surge current capability, comprising: a substrate layer 1, which is an N conductivity type silicon carbide semiconductor material, and the doping concentration range of the N type material is [1e15 / cm 3 , 1e20 / cm 3 ]; on the upper surface of the substrate layer 1 is the drift layer 2, which is an N conductivity type silicon carbide semiconductor material, its doping concentration is lower than that of the substrate layer 1, and the doping concentration range of the N-type material is [1e13 / cm 3 , 1e19 / cm 3 ], etched by RIE method on the surface of the layer to form a deep groove; ion implantation at the bottom of the trench and on both sides of the mesa forms P-type implant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com