Preparation method of soybean sauce flavored base material

A soy sauce flavor and base material technology, which is applied in the field of soy sauce and condiment production, can solve the problems not involved in the preparation method of flavor base material, achieve high ammonia nitrogen and total nitrogen content, increase ammonia nitrogen and total nitrogen content, and high yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Using 50kg of baker's yeast as raw material, add water to make the mass percentage of baker's yeast in the liquid reach 20%, autolyze at 55°C for 12 hours to obtain yeast enzymatic solution; add phosphoric acid, wherein the mass ratio of phosphoric acid to yeast enzymatic solution is 1%. Treat in a high-pressure reactor at 120°C for 2.5 hours to obtain yeast extract; adjust the pH value of yeast extract to 6.5 with sodium hydroxide, add ethanol until the volume concentration of ethanol in the system reaches 30%, reflux extraction in the condenser tube, heat to boiling, and extract Keep slightly boiling during the process, the extraction time is 1 hour, remove insoluble impurities, and obtain the supernatant, which is vacuum concentrated to a solid content of 40% by weight, wherein the temperature during the concentration is controlled at 55-58 ° C, the vacuum degree is controlled At 0.05-0.06 MPa, a soy sauce flavor base material is obtained.

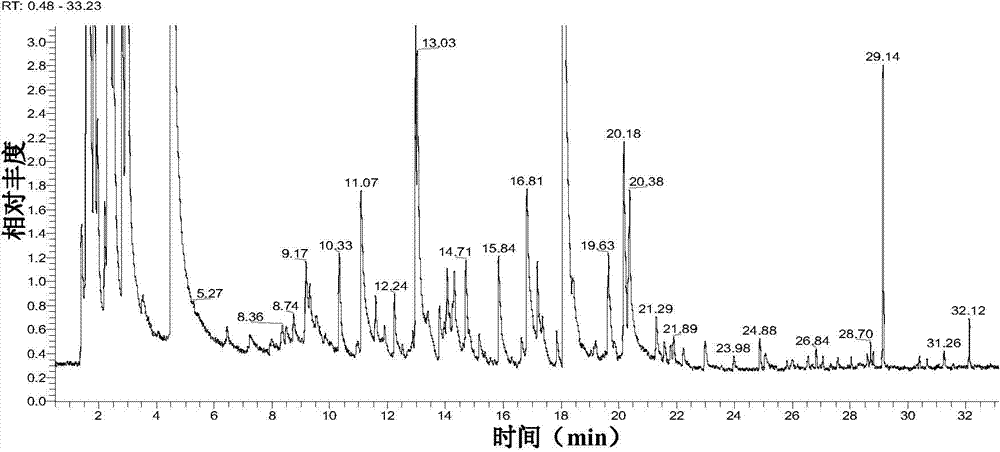

[0022] Using GC-MS to ana...

Embodiment 2

[0030] Using 50kg of baker’s yeast as raw material, add water to make the mass percentage of baker’s yeast in the liquid reach 30%, and autolyze at 50°C for 24 hours to obtain yeast enzymolysis solution; add phosphoric acid, wherein the mass ratio of phosphoric acid to yeast enzymolysis solution is 2%. Treat in a high-pressure reactor at 110°C for 2.0 hours to obtain yeast extract; adjust the pH value of yeast extract to 7.0 with sodium hydroxide, add ethanol until the volume concentration of ethanol in the system reaches 30%, reflux extraction in the condenser tube, heat to boiling, and extract Keep slightly boiling during the process, the extraction time is 2 hours, remove insoluble impurities, and obtain a supernatant, which is vacuum concentrated to a solid content of 40% by weight, wherein the temperature during the concentration is controlled at 58-60 ° C, and the vacuum degree is controlled At 0.08-0.1MPa, the soy sauce flavor base material was obtained, and the resultin...

Embodiment 3

[0032] Using 50kg of baker’s yeast as raw material, add water to make the mass percentage of baker’s yeast in the liquid reach 30%, autolyze at 50°C for 24 hours to obtain yeast enzymolysis solution; add phosphoric acid, wherein the mass ratio of phosphoric acid to yeast enzymolysis solution is 2%, in Treat in a high-pressure reactor at 110°C for 2.0 hours to obtain yeast extract; adjust the pH value of yeast extract to 7.0 with sodium hydroxide, add ethanol until the volume concentration of ethanol in the system reaches 30%, reflux extraction in the condenser tube, heat to boiling, and extract Keep slightly boiling during the process, the extraction time is 2 hours, remove insoluble impurities, and obtain a supernatant, which is vacuum concentrated to a solid content of 40% by weight, wherein the temperature during the concentration is controlled at 56-58 ° C, and the vacuum degree is controlled At 0.08-0.1MPa, the soy sauce flavor base material was obtained, and the resulting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com