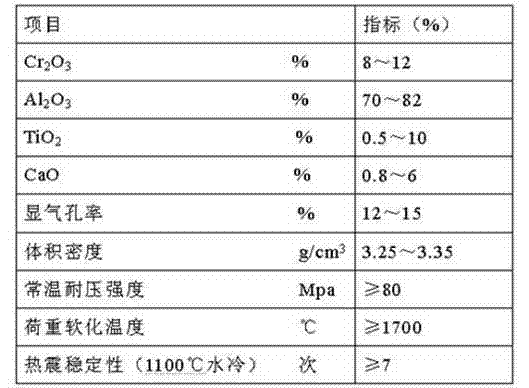

Chrome corundum-titanium brick and production method thereof

A chrome corundum titanium brick and a production method technology, applied in the field of refractory materials, can solve the problems of inability to meet use requirements, poor slag erosion resistance and thermal shock stability, and achieve good slag erosion resistance and strong slag erosion resistance. , the effect of promoting sintering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

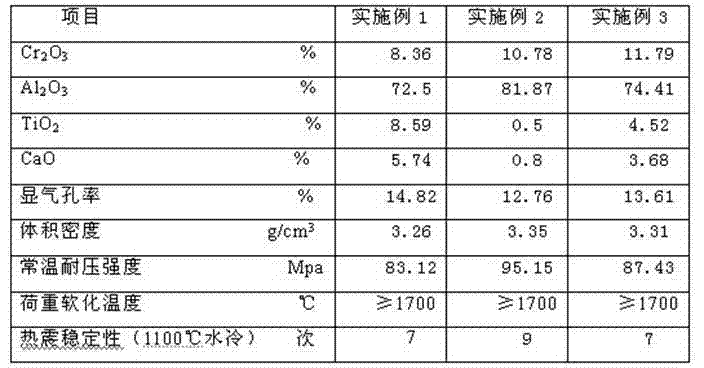

Examples

Embodiment 1

[0034] The composition of chrome corundum titanium brick is:

[0035] Chrome corundum 900kg;

[0036] High titanium slag 100kg;

[0037] Lime 80kg;

[0038] Al in the chrome corundum 2 o 3 The mass percentage content is 82% ~ 84%, Cr 2 o 3 The mass percentage content is 12%~14%, Al 2 o 3 and Cr 2 o 3 The mass percentage content of the total amount is ≥96%; the TiO in the high titanium slag 2 The mass percentage content is 90% to 94%; the CaO mass percentage content in the lime is ≥80%.

[0039] Concrete preparation steps are as follows:

[0040] a. Raw materials and processing

[0041] Crushing the chrome corundum to a particle size of ≤5mm; finely grinding the high-titanium slag to a particle size of 180 mesh; finely grinding the lime to a particle size of 180 mesh;

[0042] b. to sieve

[0043] The crushed chrome corundum is screened and classified, and the classified particle sizes are 5mm-3mm, 3mm-1mm, 1mm-0mm granular materials and 180-mesh and 325-mesh po...

Embodiment 2

[0051] The composition of chrome corundum titanium brick is:

[0052] Chrome corundum 995kg;

[0053] Titanium dioxide 5kg;

[0054] Lime 10kg;

[0055] Al in the chrome corundum 2 o 3 The mass percentage content is 82% ~ 84%, Cr 2 o 3 The mass percentage content is 12%~14%, Al 2 o 3 and Cr 2 o 3 The mass percentage content of the total amount is ≥96%; the TiO in the titanium dioxide 2 The mass percentage content is ≥ 98%; the CaO mass percentage content in the lime is ≥ 80%.

[0056] Concrete preparation steps are as follows:

[0057] a. Raw materials and processing

[0058] Crushing the chrome corundum to a particle size of ≤5mm; taking titanium dioxide with a particle size of 325 mesh; finely grinding the lime to a particle size of 180 mesh;

[0059] b. to sieve

[0060] The crushed chrome corundum is screened and classified, and the classified particle sizes are 5mm-3mm, 3mm-1mm, 1mm-0mm granular materials and 180-mesh and 325-mesh powders;

[0061] c. slee...

Embodiment 3

[0068] The composition of chrome corundum titanium brick is:

[0069] Chrome corundum 990kg;

[0070] High titanium slag 50kg;

[0071] Lime 50kg;

[0072] Al in the chrome corundum 2 o 3 The mass percentage content is 82% ~ 84%, Cr 2 o 3 The mass percentage content is 12%~14%, Al 2 o 3 and Cr 2 o 3 The mass percentage content of the total amount is ≥96%; the TiO in the high titanium slag 2 The mass percentage content is 90% to 94%; the CaO mass percentage content in the lime is ≥80%.

[0073] Concrete preparation steps are as follows:

[0074] a. Raw materials and processing

[0075] Crushing the chrome corundum to a particle size of ≤5mm; finely grinding the high-titanium slag to a particle size of 180 mesh; finely grinding the lime to a particle size of 180 mesh;

[0076] b. to sieve

[0077] The crushed chrome corundum is screened and classified, and the classified particle sizes are 5mm-3mm, 3mm-1mm, 1mm-0mm granular materials and 180-mesh and 325-mesh pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com