A kind of anti-radiation finishing processing method of fabric

A processing method and anti-radiation technology, which is applied in the processing of textile materials, liquid/gas/steam textile material processing, fiber processing, etc., can solve the problems of inapplicability, metal fiber processing and use limitations, etc., and achieve excellent cushioning, good Washing resistance, uniform look and feel effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 1

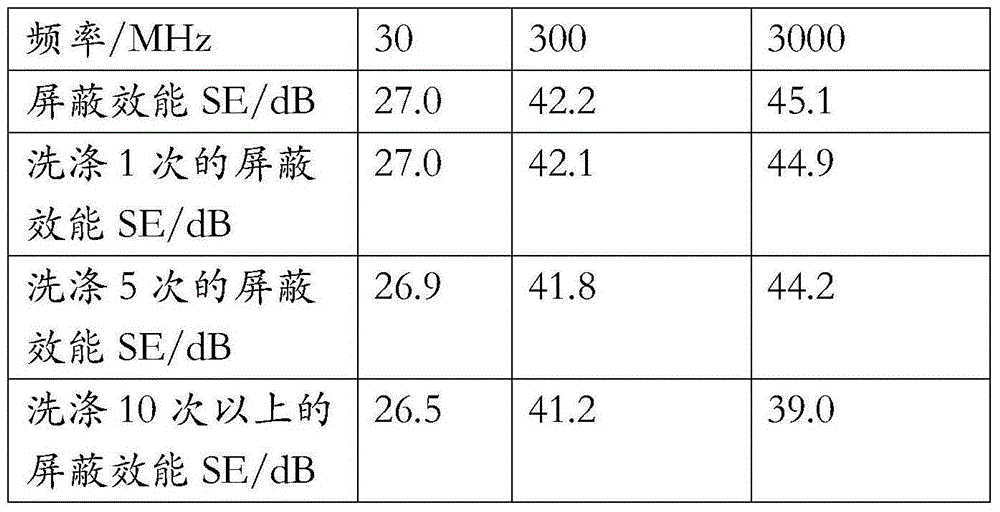

[0045] Embodiment one, 1# fabric

[0046] 1. Preparation of materials

[0047] (1) Fabric: 26sTK / 1 jersey

[0048] (2) Nano-magnetic metal absorber: self-made nano-magnetic metal particles 1#

[0049] The preparation method of nano magnetic metal particles 1#: add 2g FeCl to 500mL 2 and 5gFeCl 3 , after fully dissolved, add NaOH solution dropwise at a constant speed under the action of a stirring bar, and when the pH value rises to 6-7, Fe will be generated 3 o 4 , filter the resulting precipitate, dry it, and finally make it into nanoparticles with an ultrasonic pulverizer.

[0050] (3) Polymer adhesive: Polyurethane adhesive LF-85 (Shanghai Lifeng Chemical Technology Co., Ltd.).

[0051] 2. Anti-radiation finishing process

[0052] The anti-radiation finishing process adopts the padding and baking process, and the fabric is dried and baked after padding with the finishing solution, so that the nano-magnetic metal is attached to the fabric.

[0053] (1) Composition of...

Embodiment 2 2

[0064] Embodiment two, 2# fabric:

[0065] 1. Preparation of materials

[0066] (1) Fabric: T / C50 / 50 polyester cotton jersey

[0067] (2) Nano-magnetic metal absorber: self-made nano-magnetic metal particles 1#

[0068] (3) Polymer adhesive: Polyurethane low-temperature adhesive (Shanghai Textile Research Institute)

[0069] 2. Anti-radiation finishing process

[0070] The anti-radiation finishing process adopts the padding and baking process, and the fabric is dried and baked after padding the finishing solution, so that the nano-magnetic metal is attached to the fabric.

[0071] (1) Composition of working fluid:

[0072] Nano magnetic metal wave absorbing agent 60g / L

[0073] Polymer binder 60g / L

[0074] (2) Radiation protection finishing process curve

[0075] The fabric is dipped and rolled twice in the working solution → drying (90°C, 3min) → baking (140°C, 2min) → cooling

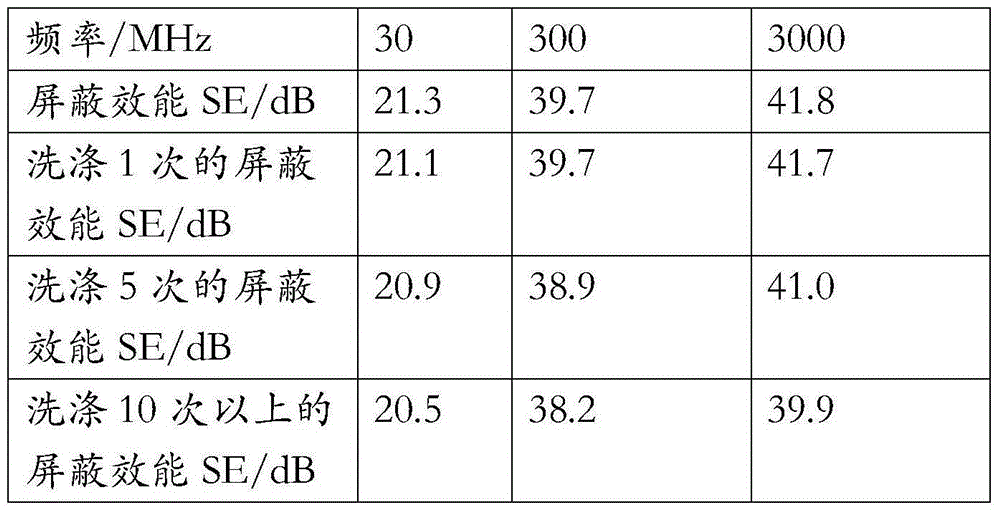

[0076] 3. Radiation protection performance test

[0077] According to GB / T23463-2009 "Pr...

Embodiment 3

[0082] Embodiment three, 3# fabric

[0083] 1. Preparation of materials

[0084] (1) Fabric: 150D pure polyester double-sided cloth

[0085] (2) Nano-magnetic metal absorber: self-made nano-magnetic metal particles 1#

[0086] (3) Polymer adhesive: Polyurethane adhesive Bilibai PUNEW (BASF).

[0087] 2. Anti-radiation finishing process

[0088] The anti-radiation finishing process adopts the padding and baking process, and the fabric is dried and baked after padding the finishing solution, so that the nano-magnetic metal is attached to the fabric.

[0089] (1) Composition of working fluid:

[0090] Nano magnetic metal wave absorbing agent 30g / L

[0091] Polymer binder 40g / L

[0092] (2) Radiation protection finishing process curve

[0093] The fabric is dipped and rolled twice in the working solution → drying (90°C, 3min) → baking (145°C, 2min) → cooling

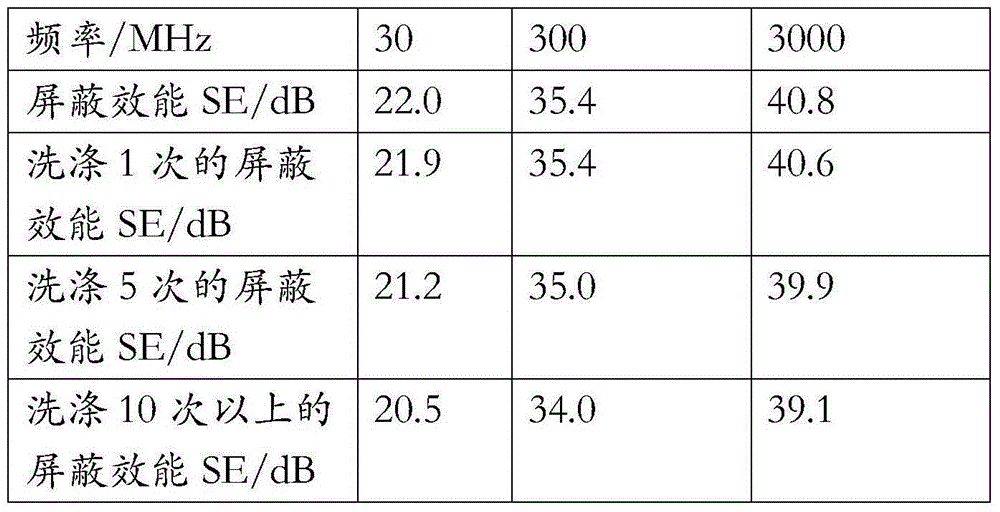

[0094] 3. Radiation protection performance test

[0095] According to GB / T23463-2009 "Protective Clothing Microwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com