Double buffer relief valve

A technology of overflow valve and double buffer, which is applied to engine components, fuel injection pumps, machines/engines, etc., can solve the problems of reduced control accuracy of fuel intake, increased gradient of fuel pressure drop, and shortened life of system components. Achieve the effect of improving reliability, reducing pressure drop gradient, and reducing oil drainage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described in more detail below in conjunction with accompanying drawing example:

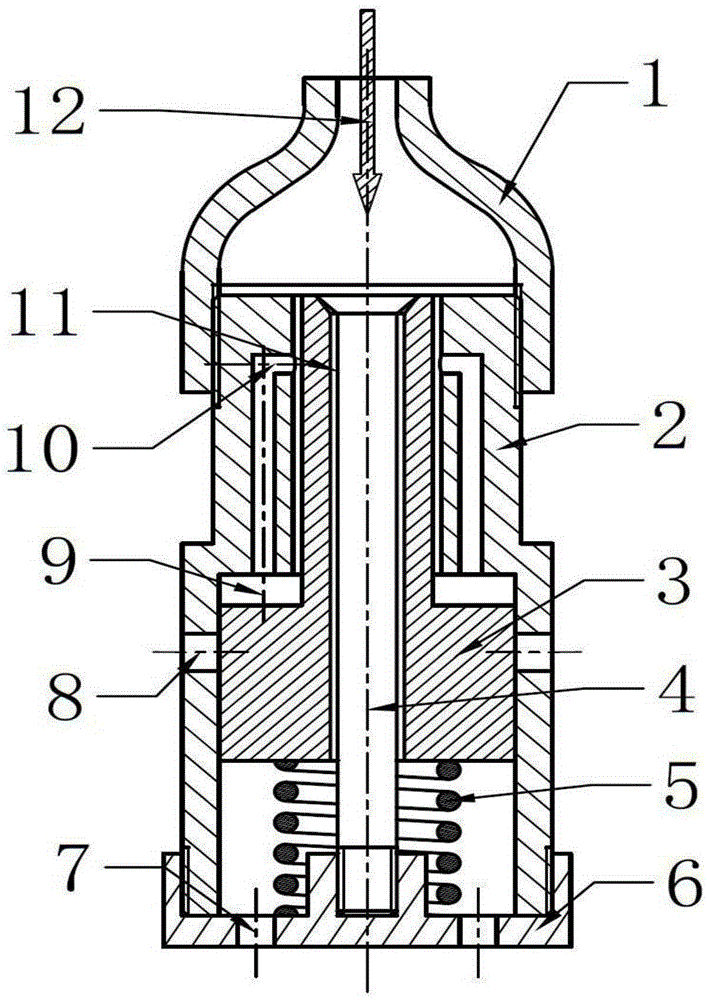

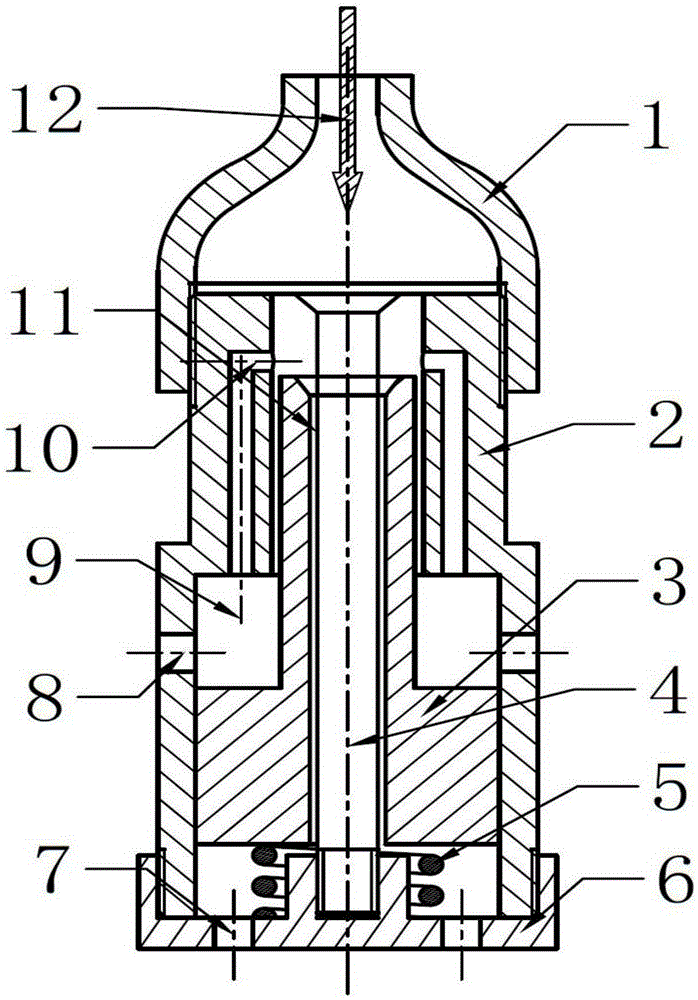

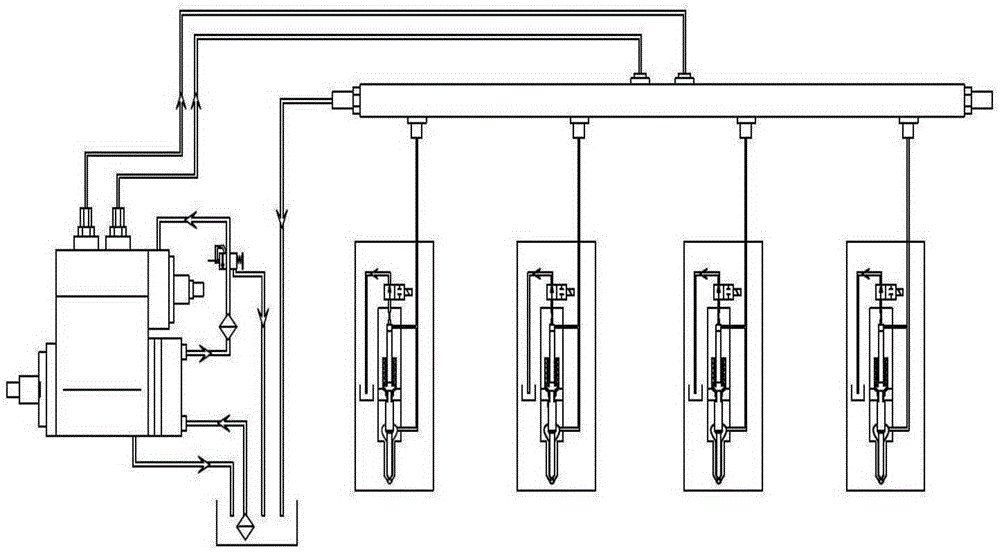

[0016] combine Figure 1~3 , the main structural components of the present invention include: oil inlet housing 1, overflow valve body 2, moving piston 3, fixed valve stem 4, return spring 5, base 6, discharge hole 7, discharge hole 8, variable volume chamber 9. Throttle hole 10, throttle oil passage 11 and oil inlet 12. The oil inlet housing 1 is installed on the upper end of the overflow valve, and the oil inlet on the oil inlet housing and the upper end surface of the overflow valve form a fixed volume chamber. The moving piston 3 adopts a variable cross-section piston, which is installed in the overflow valve body. The lower end surface of the moving piston 3 is supported by a return spring 5. The moving piston 3 is a hollow piston. On the one hand, a fixed valve stem 4 needs to be installed in the center of the moving piston 3. The moving mass of the moving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com