Full-pseudocapacitance super capacitor

A technology for supercapacitors and pseudocapacitors, applied in hybrid capacitor electrodes, hybrid capacitor collectors, etc., can solve the problems of insufficient specific capacity of supercapacitors, achieve multi-charge storage and release capacity, simple preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

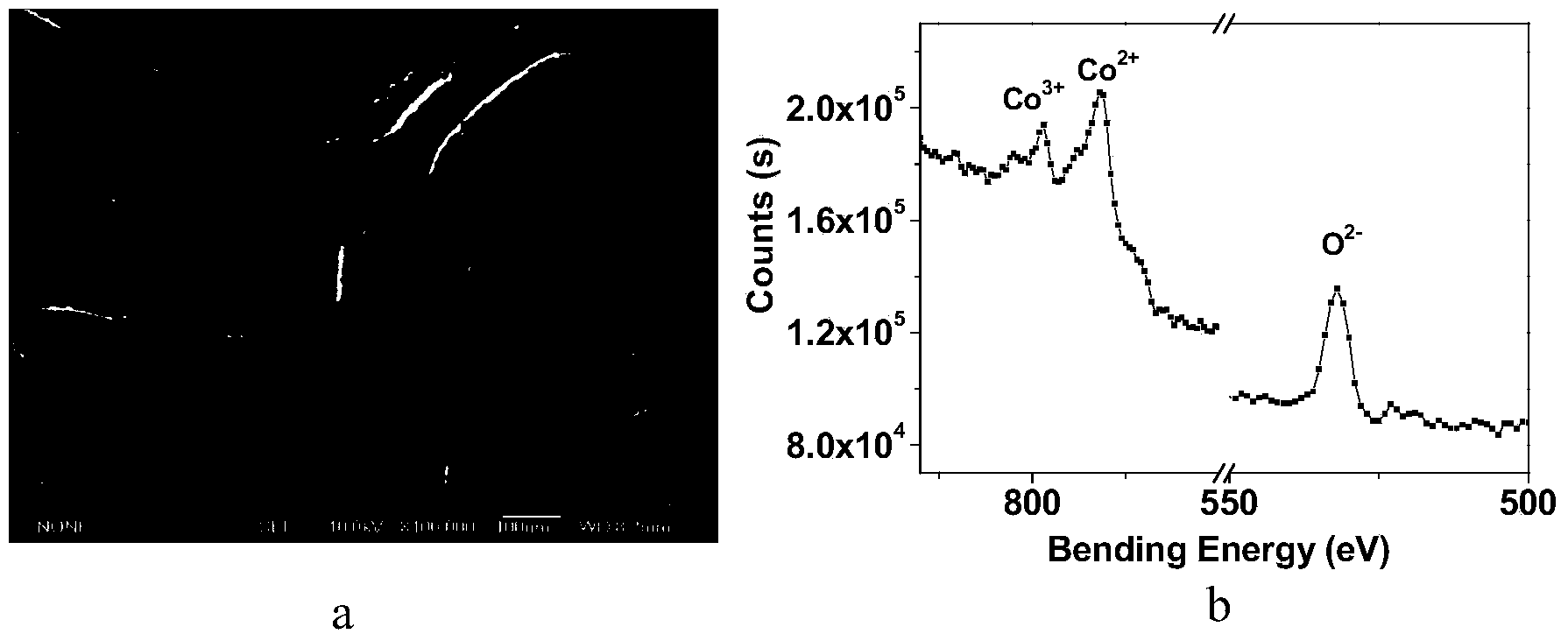

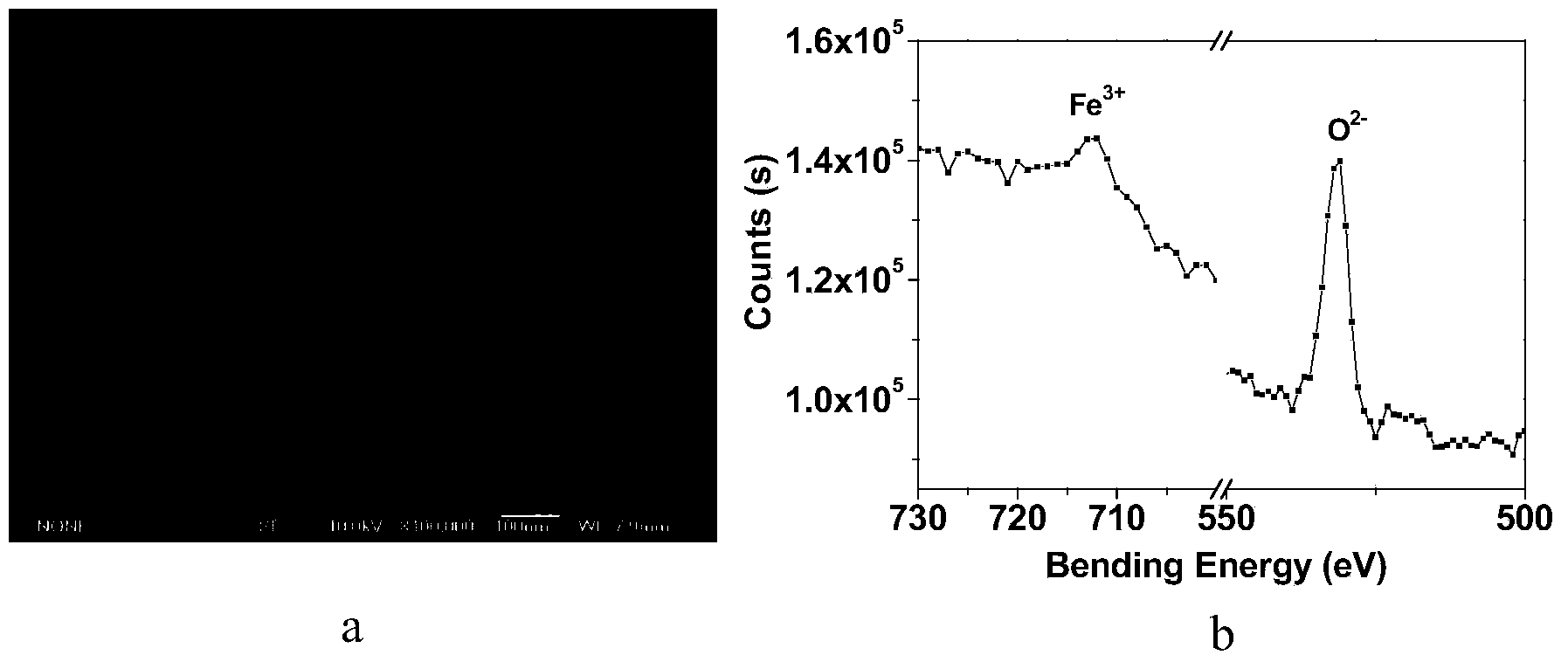

Image

Examples

Embodiment 1

[0028] (1) Preparation of multi-walled carbon nanotube / conductive carbon cloth substrate. The preparation method includes: adding 7.25 grams of nickel nitrate hexahydrate to 50 milliliters of a mixed solution of ethylene glycol and ethanol with a volume ratio of 1:1, and stirring for 20 minutes to Completely dissolve, put the solution into a spray bottle; spray the above solution evenly on the surface of the conductive carbon cloth until the conductive carbon cloth is wet, put it in the middle of the quartz tube in the tube furnace, and mix ethanol and ethyl alcohol with a volume ratio of 3:7 The diol mixture is placed on the inner edge of the furnace wall at one end of the quartz tube inlet; the tube furnace heats up, feeds 150sccm hydrogen and 50sccm argon at the same time, reaches 850 degrees Celsius and closes the hydrogen, and maintains it for 30 minutes until ethanol and ethylene diol After the alcohol mixed solution is completely volatilized, the temperature is naturally...

Embodiment 2

[0035] (1) Preparation of multi-walled carbon nanotube / conductive carbon cloth substrate. The preparation method includes: adding 3 grams of nickel nitrate hexahydrate into a mixed solution of 50 ml of ethylene glycol and ethanol, stirring until completely dissolved, and putting the solution into a spray bottle; the above solution is evenly sprayed on the surface of the conductive carbon cloth, and after the conductive carbon cloth is wet, it is placed in the middle of the quartz tube in the tube furnace, and the mixed solution of ethanol and ethylene glycol with a volume ratio of 1:5 is placed in the quartz tube At the inner edge of the furnace wall at one end of the air inlet; the tube furnace is heated up, and 150sccm hydrogen and 50sccm argon are introduced at the same time, and the hydrogen is turned off when it reaches 800 degrees Celsius, and the temperature is naturally cooled to 100 degrees Celsius after the ethanol and ethylene glycol mixture is completely volatilized....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com