Method for depositing high k gate medium on graphene material and application

A technology of graphene and gate dielectric, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of increasing the overall thickness of the gate dielectric, the influence of the process, and the reduction of carrier mobility. Increase the scope of application and solve the effect of selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

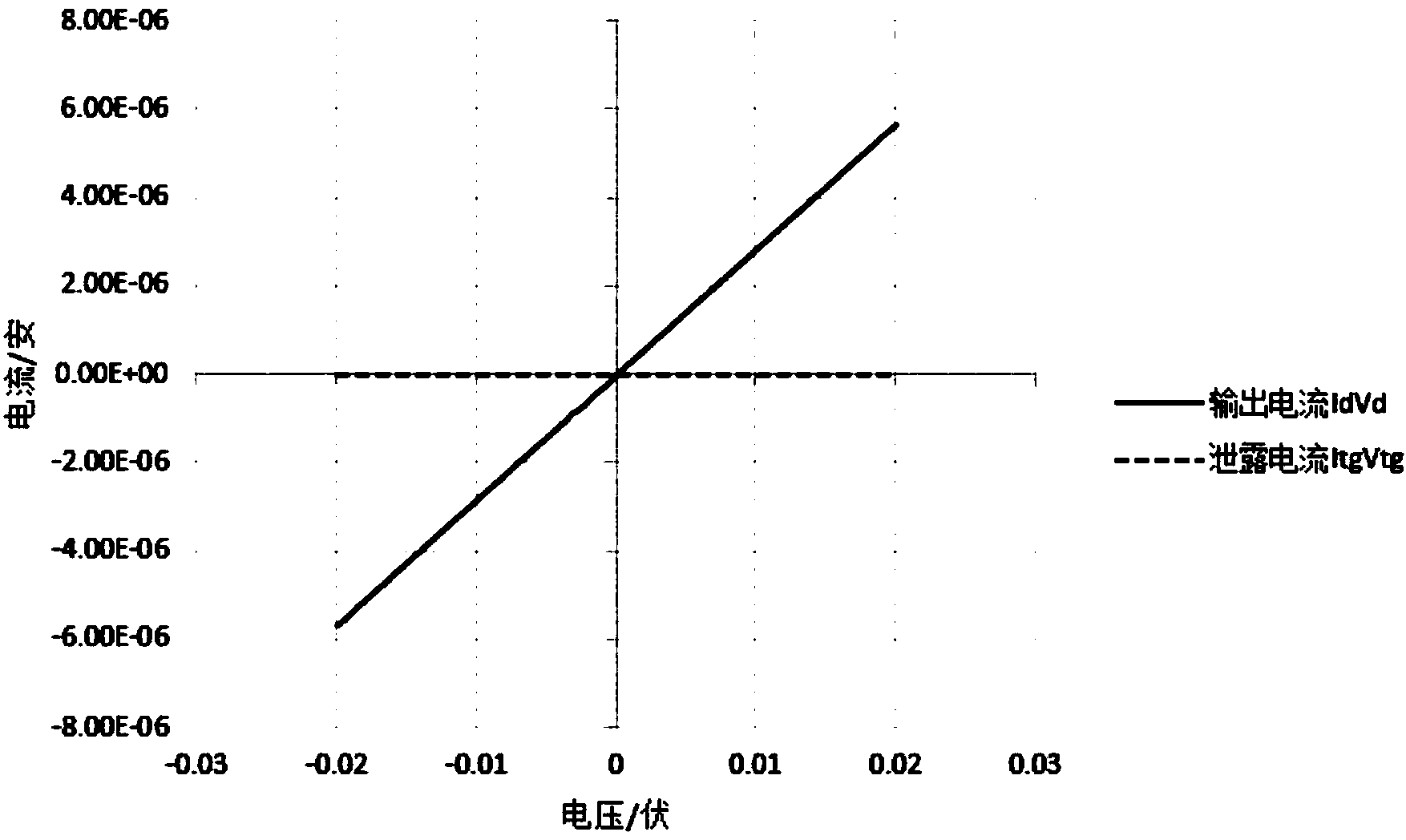

[0031] Example 1: ALD deposition of high-k dielectric on the surface of single-layer graphene

[0032] Preparation of graphene materials

[0033] Using transparent tape and highly oriented graphite flakes, graphene was prepared by mechanical exfoliation, and the substrate was 300nm thermally grown SiO on low-resistance silicon 2 .

[0034] Characterization of graphene materials.

[0035] Observe the shape and color of the prepared graphene under an optical microscope, and preliminarily determine its surface flatness and the number of graphite layers. Raman scattering spectrum was used for further characterization, the number of layers of graphene was determined according to the height ratio of G peak and 2D peak, and the surface defects of graphene were judged according to the height of D peak. Single-layer and defect-free graphene is selected as the sample, that is, the ratio of the G peak to the 2D peak of the Raman spectrum is about 0.5, and there is no obvious D peak. ...

Embodiment 2

[0042] Example 2: ALD deposition of high-k dielectric on the surface of exfoliated multilayer graphene

[0043] Preparation of graphene materials.

[0044] Using transparent tape and highly oriented graphite flakes, graphene was prepared by mechanical exfoliation, and the substrate was 300nm thermally grown SiO on low-resistance silicon 2 .

[0045] Characterization of graphene materials.

[0046] Observe the shape and color of the prepared graphene under an optical microscope, and preliminarily determine its surface flatness and the number of graphite layers. Raman scattering spectrum was used for further characterization, the number of layers of graphene was determined according to the height ratio of G peak and 2D peak, and the surface defects of graphene were judged according to the height of D peak. The graphene with multiple layers and no defects is selected as the sample, that is, the ratio of the G peak to the 2D peak of the Raman spectrum is greater than 0.5, and t...

Embodiment 3

[0053] Example 3: ALD deposition of high-k dielectric on CVD graphene

[0054] Preparation of graphene materials.

[0055] Under the catalysis of copper foil, graphene is grown by CVD, and the process of PMMA wet transfer is used to obtain uniform single-layer graphene.

[0056] Characterization of graphene materials.

[0057] Observe the shape and color of the prepared graphene under an optical microscope to preliminarily determine the uniformity of the graphene surface. Raman scattering spectrum was used for further characterization, the number of layers of graphene was determined according to the height ratio of G peak and 2D peak, and the surface defects of graphene were judged according to the height of D peak. Single-layer and defect-free graphene is selected as the sample, that is, the ratio of the G peak to the 2D peak of the Raman spectrum is about 0.5, and there is no obvious D peak.

[0058] The samples were pretreated by electron beam scanning.

[0059] Put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| relative permittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com